Heat exchange system for cryogenic separation device for coal gasification device feed gas methane

A cryogenic separation and heat exchange system technology, applied in the field of heat exchange systems, can solve the problems of affecting product synthesis rate, increasing energy consumption, disadvantages, etc., and achieve the effects of reducing irreversible loss, convenient start and stop, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

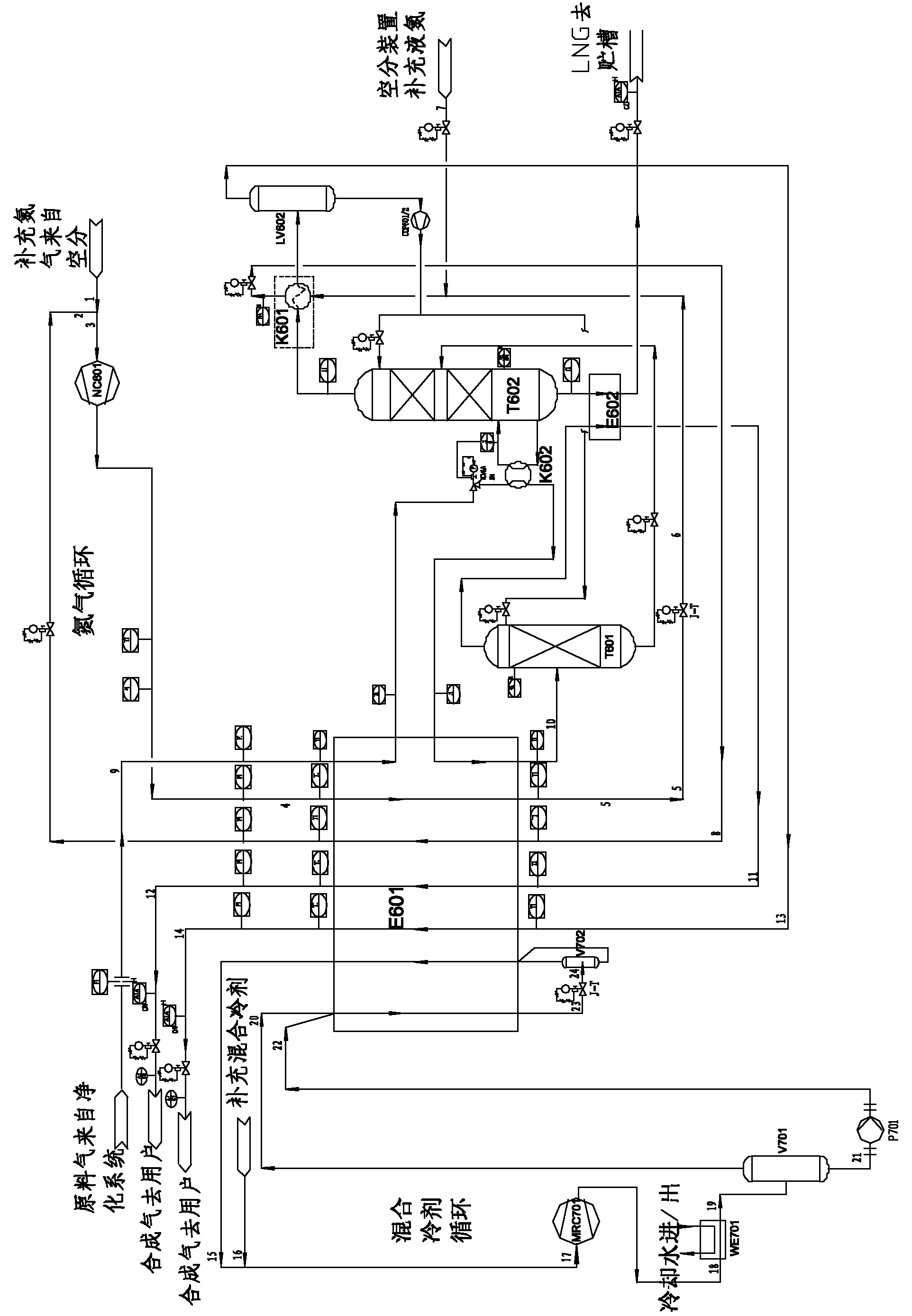

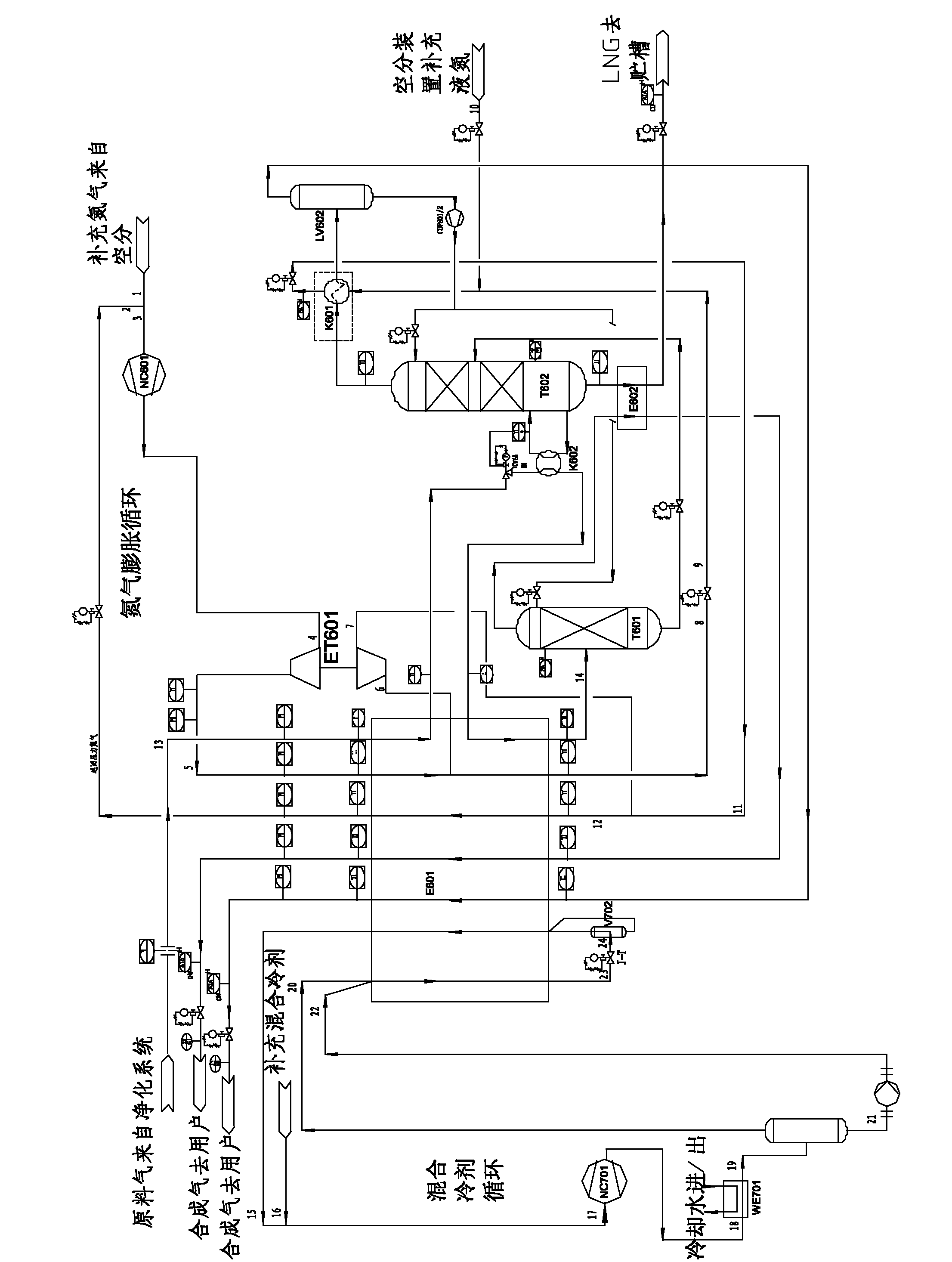

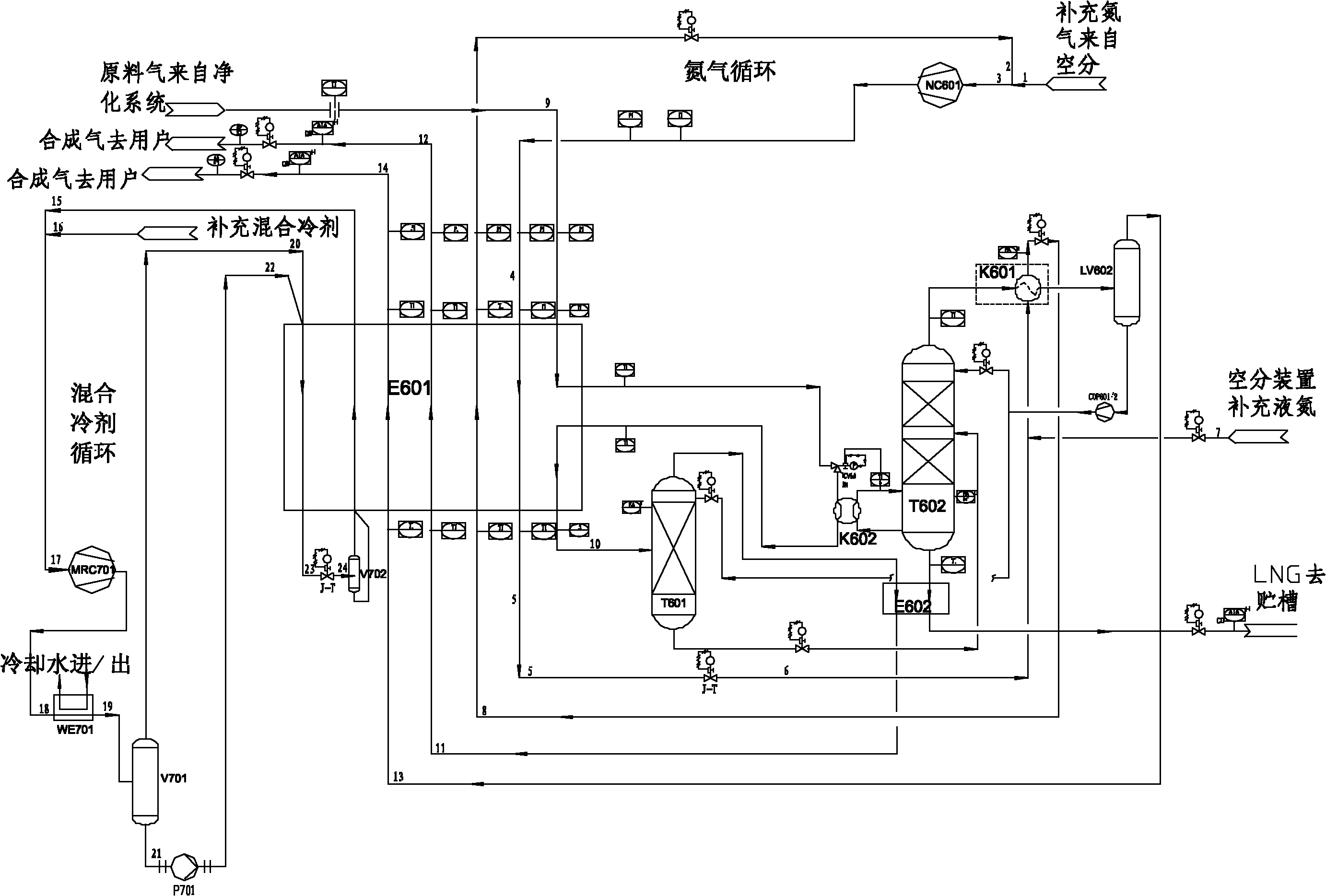

[0017] Specific embodiment 1 of the present invention, as figure 1 Shown, a coal gasification device to CH 4 The heat exchange system of the cryogenic separation unit includes a plate-fin main heat exchanger (E601), a closed mixed refrigerant cycle compressor (MRC701) and a nitrogen cycle compressor (NC601). The raw material gas is connected to the raw material gas inlet channel in the main heat exchanger and cooled therein, then extracted from the middle of the main heat exchanger, and then enters the raw material heat exchange gas channel in the main heat exchanger after being further cooled by the reboiler (K602) Cool and partially condense to -165°C ~ -160°C and lead to the washing tower (T601); the inlet and outlet of the mixed refrigerant heat exchange channel in the main heat exchanger are respectively connected to the closed mixed refrigerant cycle, and the inlet end is connected to the mixed refrigerant. The separator at the outlet of the final stage of the refrigera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com