Lithium-ion battery preparation method and battery prepared

A lithium-ion battery and battery technology, which is applied in the direction of battery electrodes, electrolyte storage battery manufacturing, secondary batteries, etc., can solve the problems of low initial charge and discharge efficiency and low initial discharge capacity, so as to improve the initial charge and discharge efficiency and improve the first discharge Capacity, the effect of increasing energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] In the preparation method of the present invention, a layer of SEI film is first formed on the negative electrode sheet, and then assembled with the positive electrode sheet to form a battery. The specific steps are:

[0029] ①Firstly, according to the conventional ratio and process, carry out the negative electrode ingredients, coating and other processes to prepare the negative electrode sheet required by a certain type of ordinary lithium-ion battery, and take a certain size of the separator used by the conventional battery to wrap the negative electrode sheet (in case the lithium ion is not passed through. The diaphragm is directly embedded in the negative electrode sheet), and the negative electrode sheet A required for the experiment is obtained;

[0030] ② Prepare lithium salt, organic solvent and appropriate amount of additives according to the conventional ratio to obtain electrolyte B;

[0031] ③Put pole piece A into solution B, and take a certain amount of m...

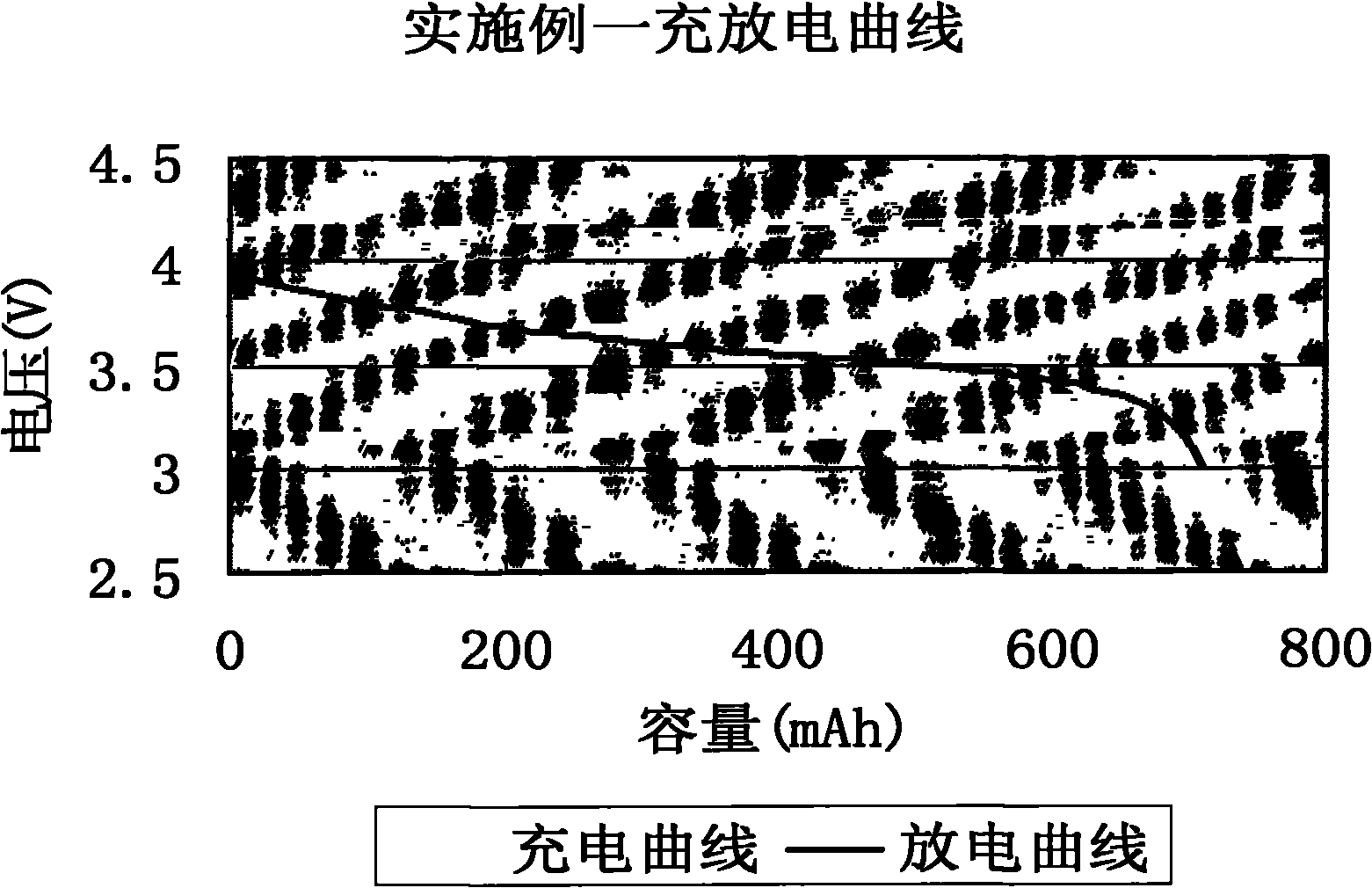

Embodiment 1

[0037] 1. Weigh 100g of graphite, 2.5g of conductive agent, 1.5g of dispersant and 4g of thickener and dissolve them in a certain amount of water, and then apply them according to the process requirements of 423048AHJ. After baking, the negative electrode sheet required for the experiment is obtained A;

[0038] 2. Weigh 1mol of LiPF6 and dissolve it in the EC solution to obtain 1mol / L LiPF6 electrolyte solution B, and add one or more of film-forming additives such as VC and PS to make the SEI film formed by the pole piece more uniform and dense;

[0039] 3. Weigh a certain amount of metal lithium sheet according to the capacity ratio, so that the capacity of the lithium sheet should be 1.05-1.1 times that of graphite; remove the oxide layer on the surface as the counter electrode C, and its size is the same as or slightly larger than that of the graphite electrode sheet ;

[0040] 4. Wrap the pole piece A with a separator, and put it into the electrolyte solution containing...

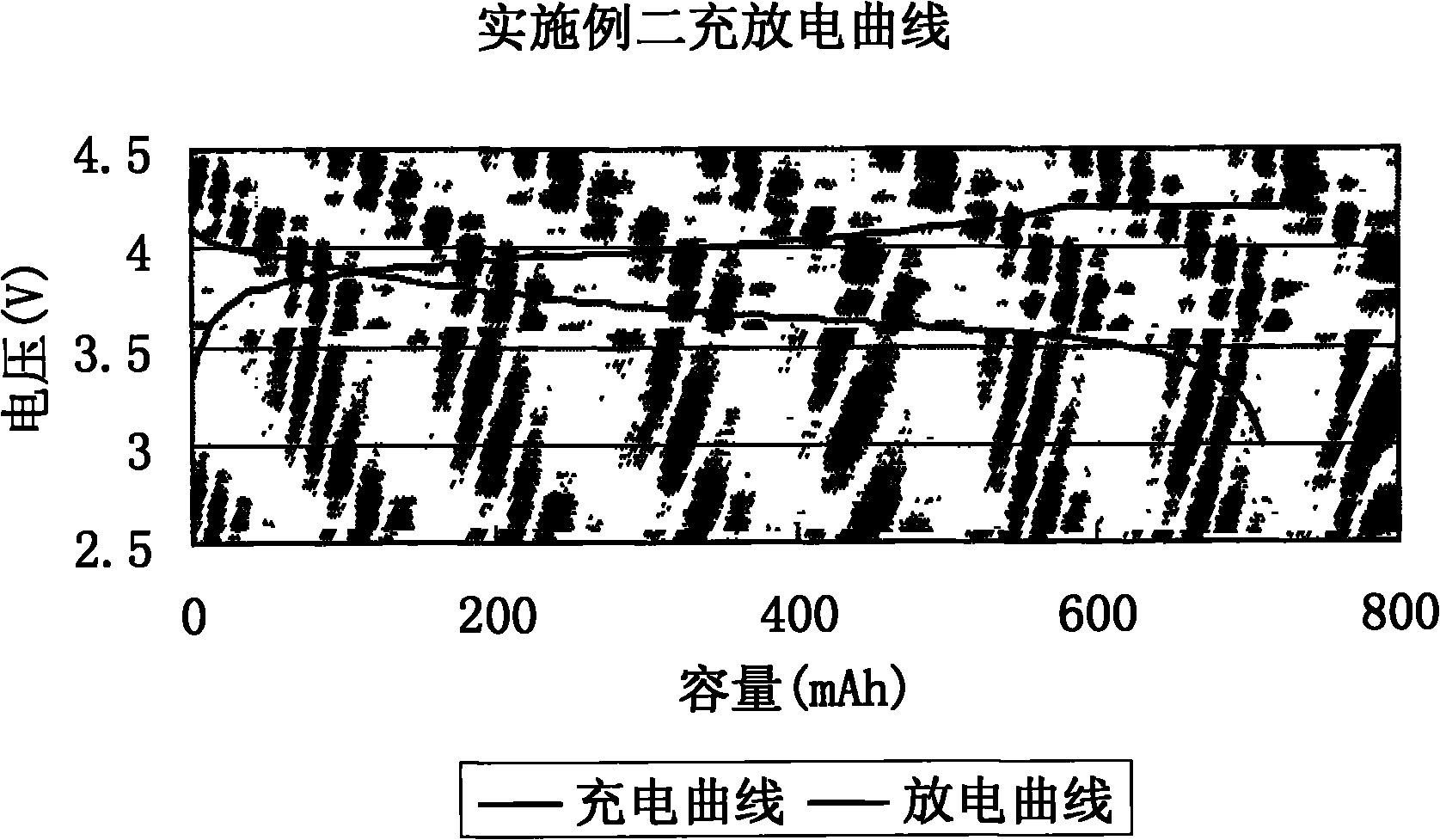

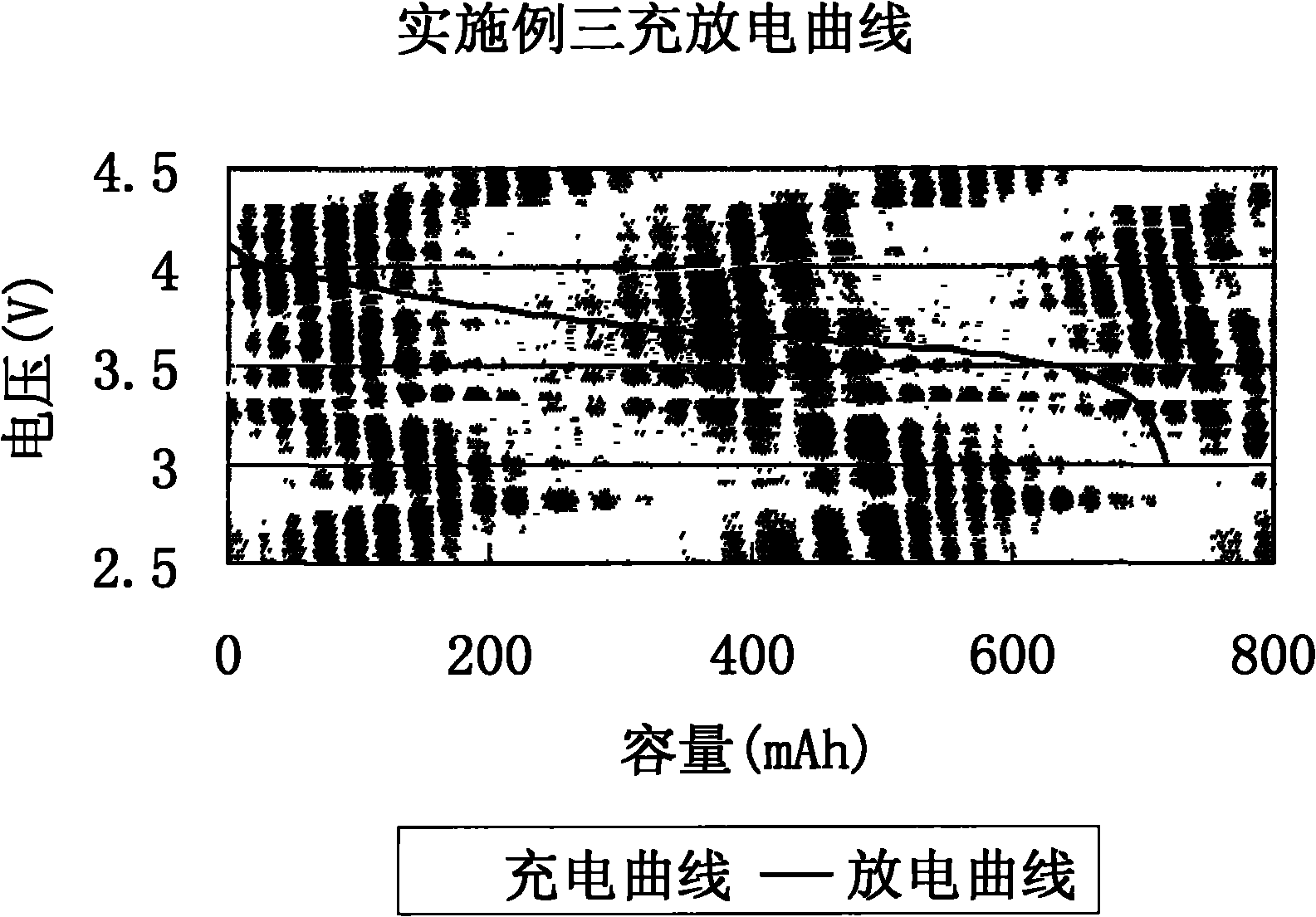

Embodiment 2

[0044] 1. Weigh 100g of graphite, 2.5g of conductive agent, 1.5g of dispersant and 4g of thickener and dissolve them in a certain amount of water, and then apply them according to the process requirements of 423048AHJ. After baking, the negative electrode sheet required for the experiment is obtained A;

[0045] 2. Weigh 1mol of LiPF6 and dissolve it in the solution of EC:DMC=3:7 to obtain 1mol / L LiPF6 electrolyte solution B;

[0046] 3. Weigh a certain amount of metal lithium sheet according to the capacity ratio, so that the capacity of the lithium sheet should be 1.05-1.1 times that of graphite; remove the oxide layer on the surface as the counter electrode C, and its size is the same as or slightly larger than that of the graphite electrode sheet ;

[0047]4. Wrap the pole piece A with a separator, put it together with the counter electrode C into the electrolyte solution containing LiPF6, let it stand for more than 10 hours, charge and discharge the simulated half-cell t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com