Energy-saving system for multi-heat-source industry heating of thermal power plant and intelligent control method of energy-saving system

An energy-saving system, multi-heat source technology, applied in steam application, steam engine installation, combined combustion mitigation, etc., can solve the problems of no port provided, high energy consumption, unadjustable temperature parameters of the hot press, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0071] Example.

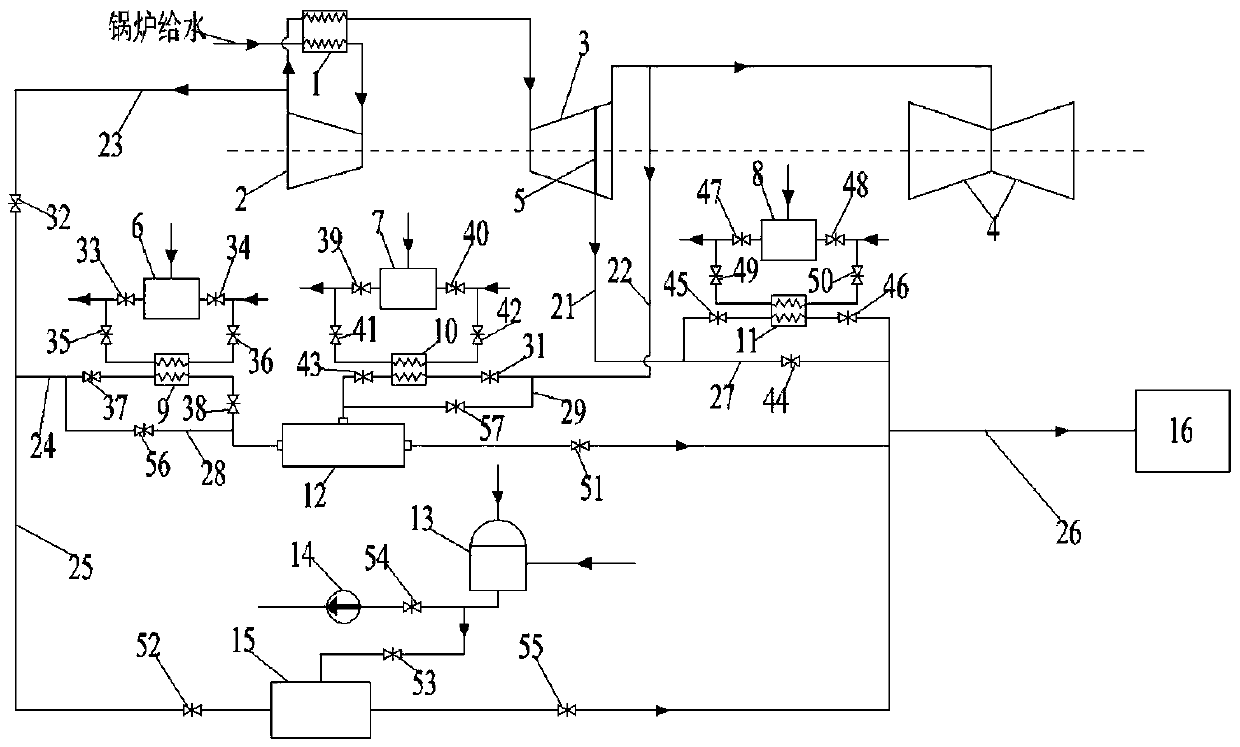

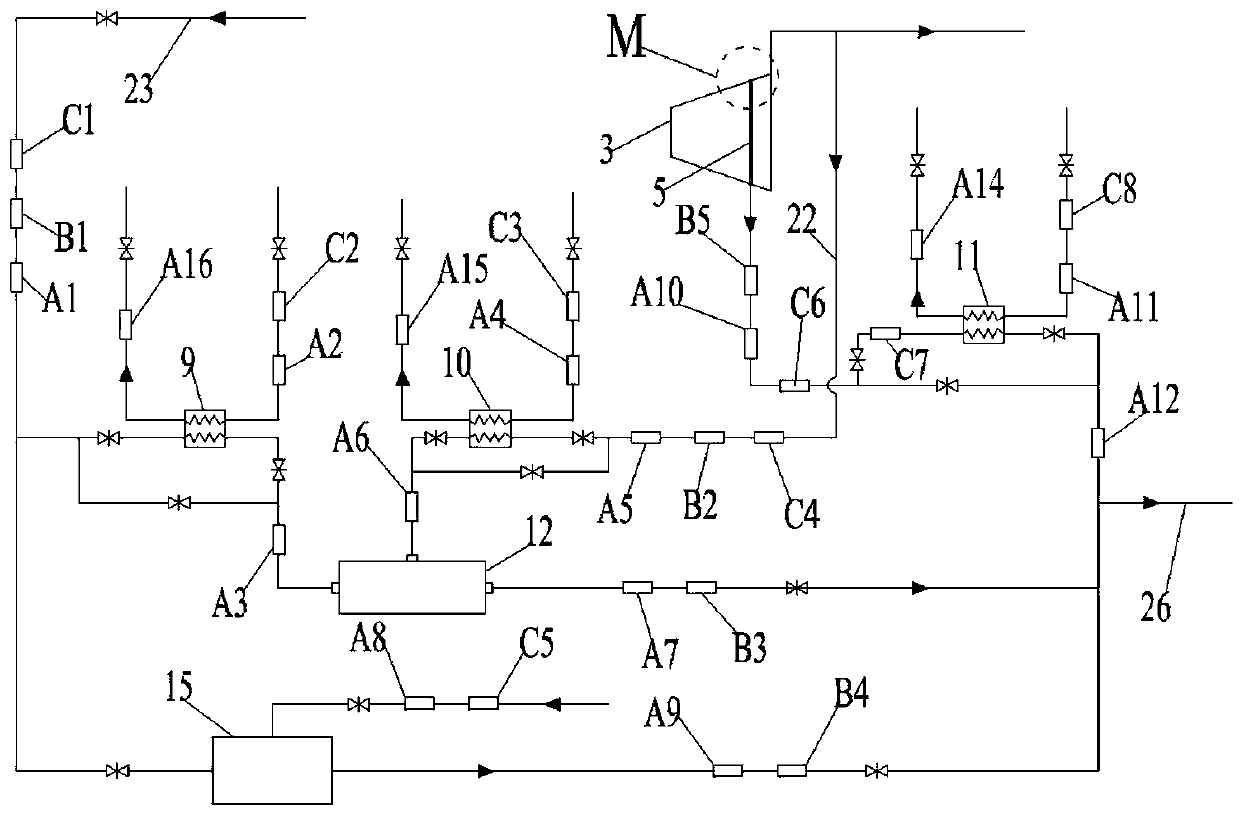

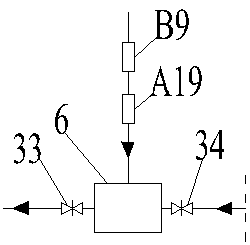

[0072] see Figure 1-7 , this embodiment relates to an energy-saving system for industrial heat supply with multiple heat sources in a thermal power plant, including a boiler 1, a steam turbine high-pressure cylinder 2, a steam turbine medium-pressure cylinder 3, a steam turbine low-pressure cylinder 4, a rotating partition 5, and an h-level regenerative heater 6. k-level regenerative heater 7, j-level regenerative heater 8, first heat exchanger 9, second heat exchanger 10, third heat exchanger 11, pressure matcher 12, deaerator 13, feeder Water pump 14, temperature and pressure reducer 15 and steam user 16.

[0073] The boiler 1, the steam turbine high-pressure cylinder 2, the steam turbine medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com