Turbine with deep peak regulation function and thermodynamic system

A thermal system and steam turbine technology, which is applied in the direction of steam engine devices, steam generation, mechanical equipment, etc., can solve the problems of waste of clean energy, inability to be fully utilized, and loss of peak-shaving ability of heating units.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

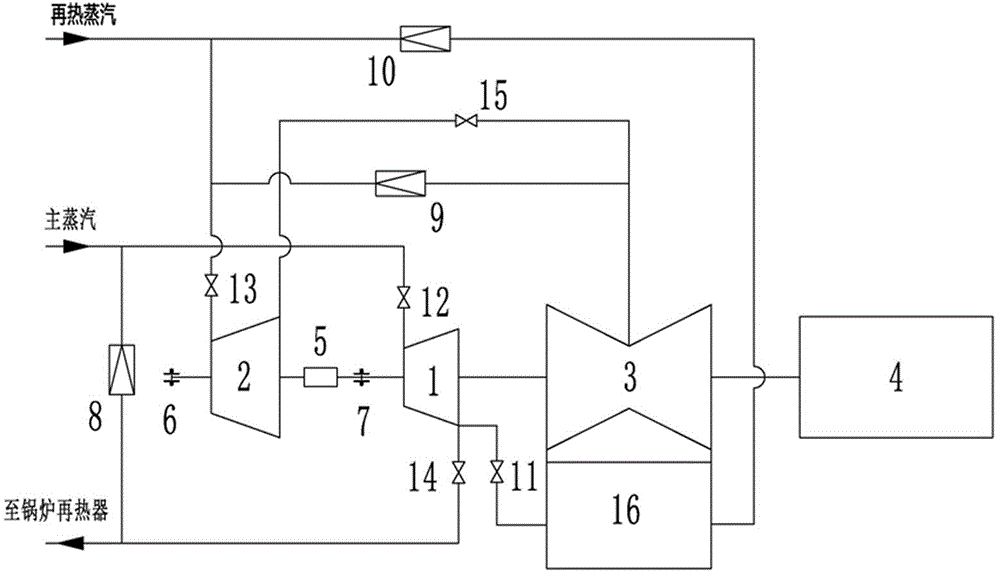

Embodiment 1

[0013] Embodiment 1: A steam turbine and thermal system with deep peak regulation function, including high-pressure cylinder 1, medium-pressure cylinder 2, low-pressure cylinder 3, generator 4, synchronous automatic clutch 5, first thrust bearing 6, and second thrust bearing 7. Medium pressure bypass valve 9, high pressure exhaust steam ventilation valve 11, high pressure steam inlet regulating valve 12, medium pressure steam inlet regulating valve 13, high pressure exhaust steam check valve 14, medium pressure exhaust steam butterfly valve 15, steam exhaust device 16 , in the shaft system of the unit, the medium pressure cylinder 2, high pressure cylinder 1, low pressure cylinder 3, and generator 4 are connected in sequence, and a synchronous automatic clutch 5 is set between the medium pressure cylinder 2 and the high pressure cylinder 1, and the steam inlet of the medium pressure cylinder 2 The first thrust bearing 6 is set on the side, and the second thrust bearing 7 is set...

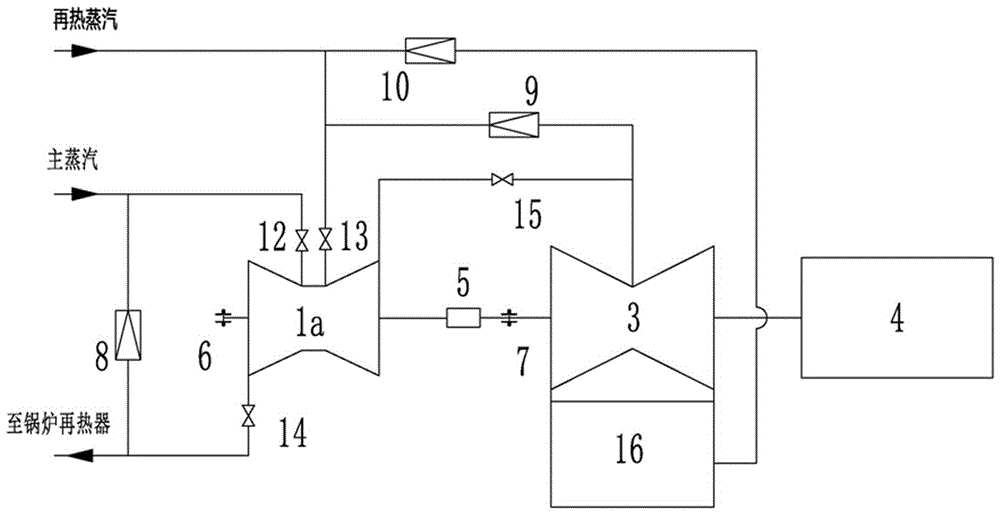

Embodiment 2

[0015] Embodiment 2: A steam turbine and thermal system with deep peak regulation function, including high and medium pressure cylinder 1a, low pressure cylinder 3, generator 4, synchronous automatic clutch 5, first thrust bearing 6, second thrust bearing 7, high pressure inlet Steam regulating valve 12, medium pressure steam inlet regulating valve 13, high pressure exhaust steam check valve 14, medium pressure exhaust steam butterfly valve 15, exhaust device 16, in the unit shaft system, high and medium pressure cylinder 1a, low pressure cylinder 3, generator 4 connected in sequence, a synchronous automatic clutch 5 is set between the high and medium pressure cylinder 1a and the low pressure cylinder 3, the first thrust bearing 6 is set on the high pressure exhaust side of the high and medium pressure cylinder 1a, and the side of the low pressure cylinder 3 close to the synchronous automatic clutch 5 is set The second thrust bearing 7, the main steam pipeline is connected to t...

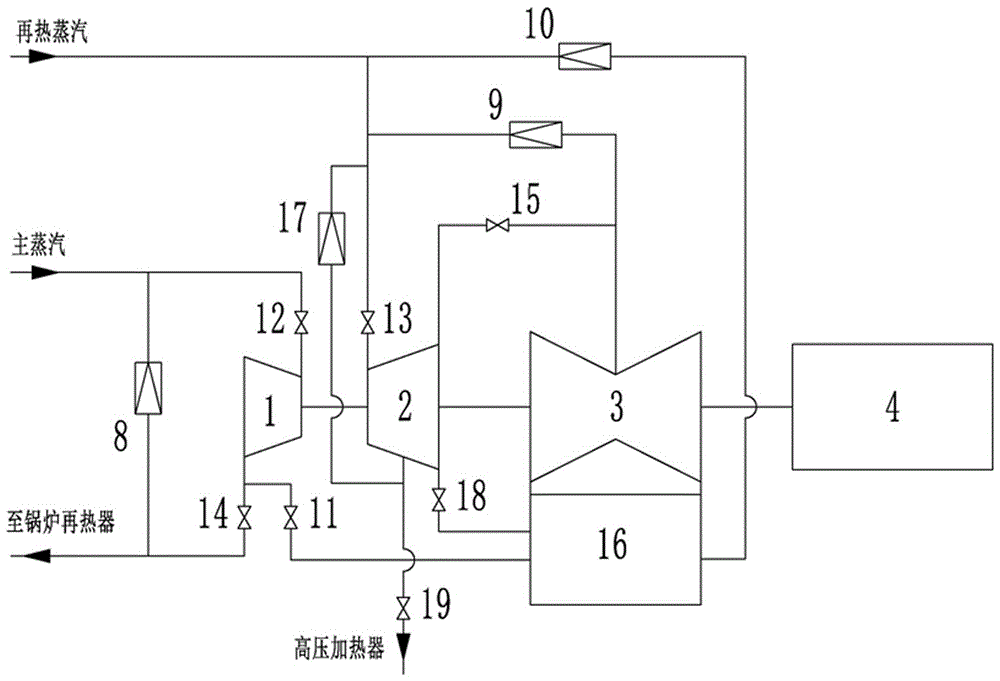

Embodiment 3

[0017] Embodiment 3: A steam turbine and thermal system with deep peak regulation function, including high-pressure cylinder 1, medium-pressure cylinder 2, low-pressure cylinder 3, generator 4, high-pressure exhaust steam ventilation valve 11, high-pressure steam inlet regulating valve 12, medium Pressure inlet steam regulating valve 13, high pressure exhaust steam check valve 14, medium pressure exhaust steam butterfly valve 15, steam exhaust device 16, reheat steam desuperheating and pressure reducing device 17, medium pressure exhaust steam ventilation valve 18, steam extraction check valve 19. In the shaft system of the unit, the high-pressure cylinder 1, the medium-pressure cylinder 2, the low-pressure cylinder 3, and the generator 4 are connected in sequence, and the main steam pipeline is connected to the steam inlet end of the high-pressure cylinder 1 through the high-pressure steam inlet regulating valve 12, and the high-pressure cylinder 1 The exhaust end of the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com