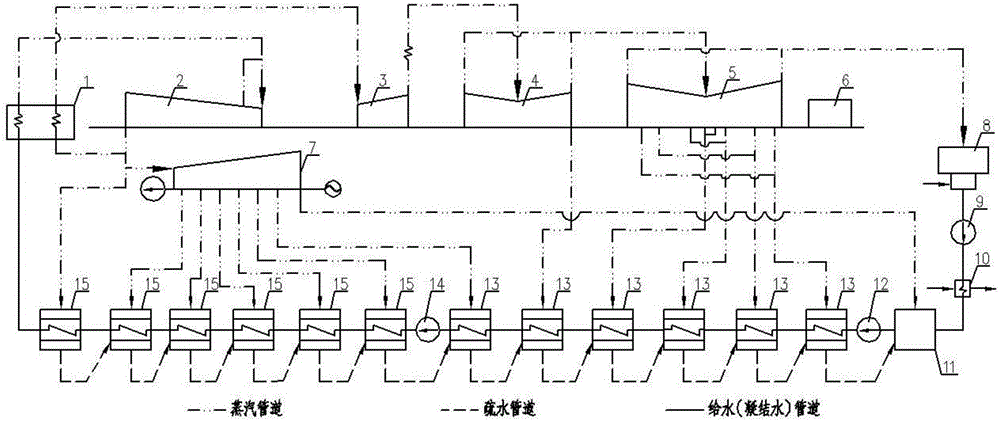

Secondary reheating double-machine back-heating thermodynamic system without deaerator for ultra-supercritical unit

An ultra-supercritical unit, double reheating technology, applied in feed water heaters, machines/engines, preheating, etc., can solve the problems of increasing the distance between the boiler room and the turbine room, large energy loss, and large superheat. Achieve the effects of reducing exhaust back pressure, low energy grade and increasing power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

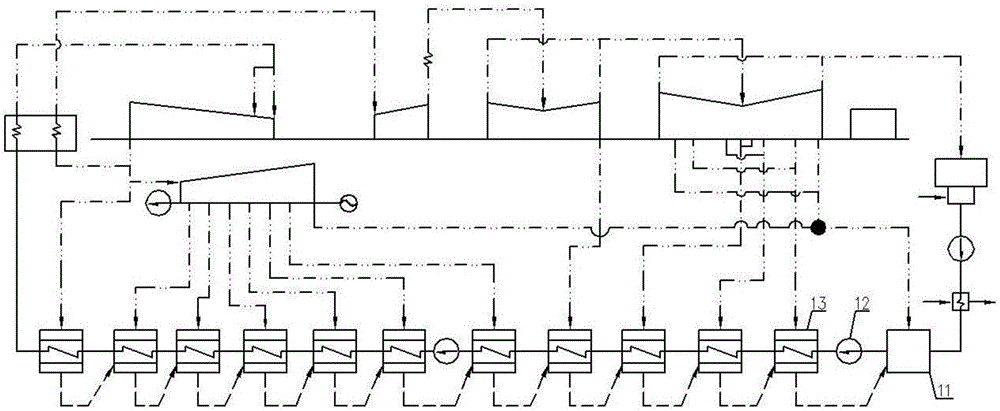

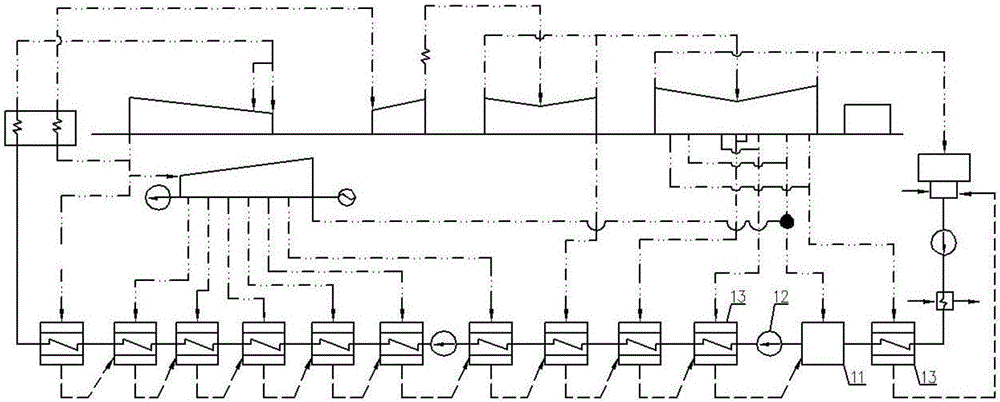

[0050] The present invention is described in detail below in conjunction with accompanying drawing:

[0051] The technical solution of the present invention is a deaerator-free device equipped with an EC-BEST dual-machine reheating system, which can remove the deaerator, reduce large-capacity high-temperature and high-pressure equipment, and improve the safety of the unit; it can reduce the exhaust steam of the BEST steam turbine. The back pressure increases the power generation of the BEST steam turbine; it can eliminate the pre-pump and simplify the boiler feed water process; it can reduce the difficulty of unit operation control; it can reduce the head of the condensate pump; it can save power consumption and improve unit efficiency; Basic investment; can reduce system cost; can reduce condenser cold end loss, improve unit economy; can reduce the superheat degree of steam extraction of steam turbine, improve unit economical ultra-supercritical double reheat unit thermal syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com