Method for detecting internal leakage of valve of thermodynamic system in power plant

A technology of a thermal system and a detection method, which is applied in the technical field of economic operation, can solve the problems of inability to obtain valves, leaking working medium flow, etc., and achieve the effects of improving operating economy, reducing leakage flow, and reducing coal consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

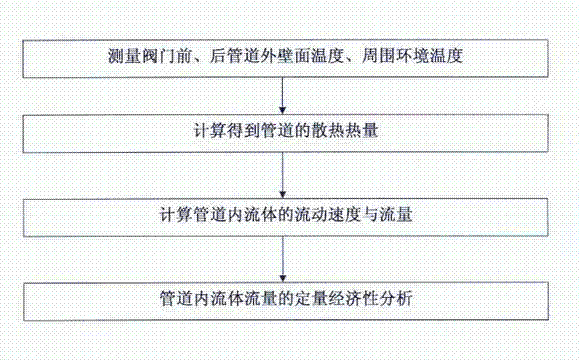

[0020] see figure 1 , the present invention provides a method for detecting internal leakage of a valve in a thermal system of a power plant, comprising the following steps:

[0021] (1) Measure the temperature of the outer wall surface of the front and rear pipes and the ambient temperature of the valve;

[0022] (2) Calculate the heat dissipation heat of the pipeline;

[0023] (3) Calculate the flow velocity and flow rate of the fluid in the pipeline;

[0024] (4) Quantitative economic analysis of the fluid flow in the pipeline.

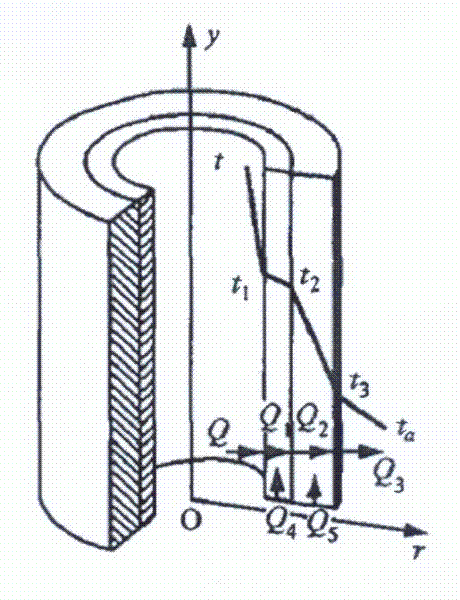

[0025] see figure 2 , the principle of a valve internal leakage detection method of a thermal system of a power plant of the present invention is as follows: According to the principle of heat transfer, when the valve has a working fluid leakage, there is steam or water and other working fluids with a temperature high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com