Boiler-turbine coupled flue gas waste heat utilization system capable of preheating air based on condensed water

A technology of flue gas waste heat and preheating air, applied in the directions of preheating, feed water heater, steam boiler, etc., can solve the problems of no consideration of restrictions, single form, low temperature sulfuric acid dew point corrosion, etc., achieving significant economic benefits and functional ability low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention proposes a waste heat utilization system of flue gas coupled with a machine furnace based on condensed water preheating air. The following will be described in conjunction with the accompanying drawings and examples.

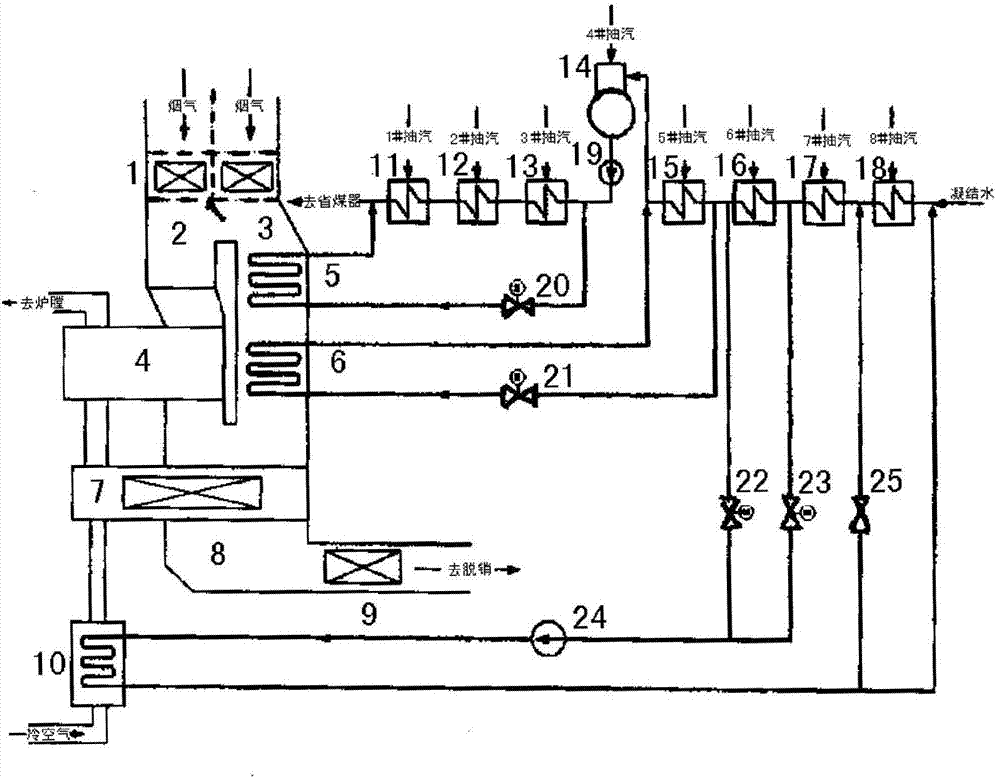

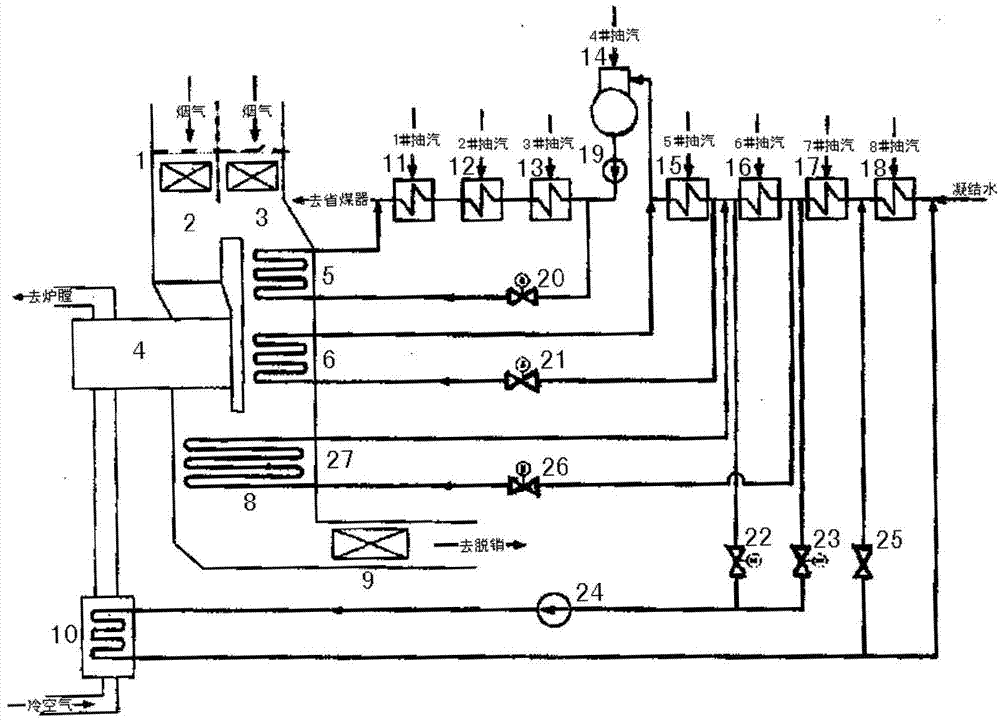

[0017] Such as figure 1 In the schematic diagram of the machine-furnace coupled flue gas waste heat utilization system based on condensed water preheating air shown, after the main flue 2 and the bypass flue 3 are connected in parallel, the upper end is connected to the main economizer 1, and the lower end is connected to the confluent flue 8 , the first-stage smoke-water heat exchanger 5 and the second-stage smoke-water heat exchanger 6 are set in turn in the bypass flue 3, and the flue gas-air heater 7 is set in the confluent flue 8; the main air preheater 4 Connect the combined flue 8, the main flue 2 and the flue gas-air heater 7 respectively; the air side of the flue gas-air heater 7 is respectively connected to the condensate-air heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com