Large concrete block for lifting a crane, method for manufacturing same, and method for installing same

A concrete block and crane technology, which is applied in transportation and packaging, building construction, infrastructure engineering, etc., can solve problems such as difficulty in manufacturing concrete blocks, easy corrosion of lifting ring components, and increased construction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those of ordinary skill in the art can easily implement the present invention. The present invention can be implemented in various ways and is not limited to the embodiments described below. In addition, in order to explain the present invention more clearly, parts not related to the present invention should be omitted in the drawings. Reference should be made to the drawings, wherein like reference numerals are used throughout the different drawings to designate like parts.

[0050] In the specification, when the descriptive phrase "a part includes a member" is used, it means that the part may also include other components without excluding these other components, as long as no special description is given.

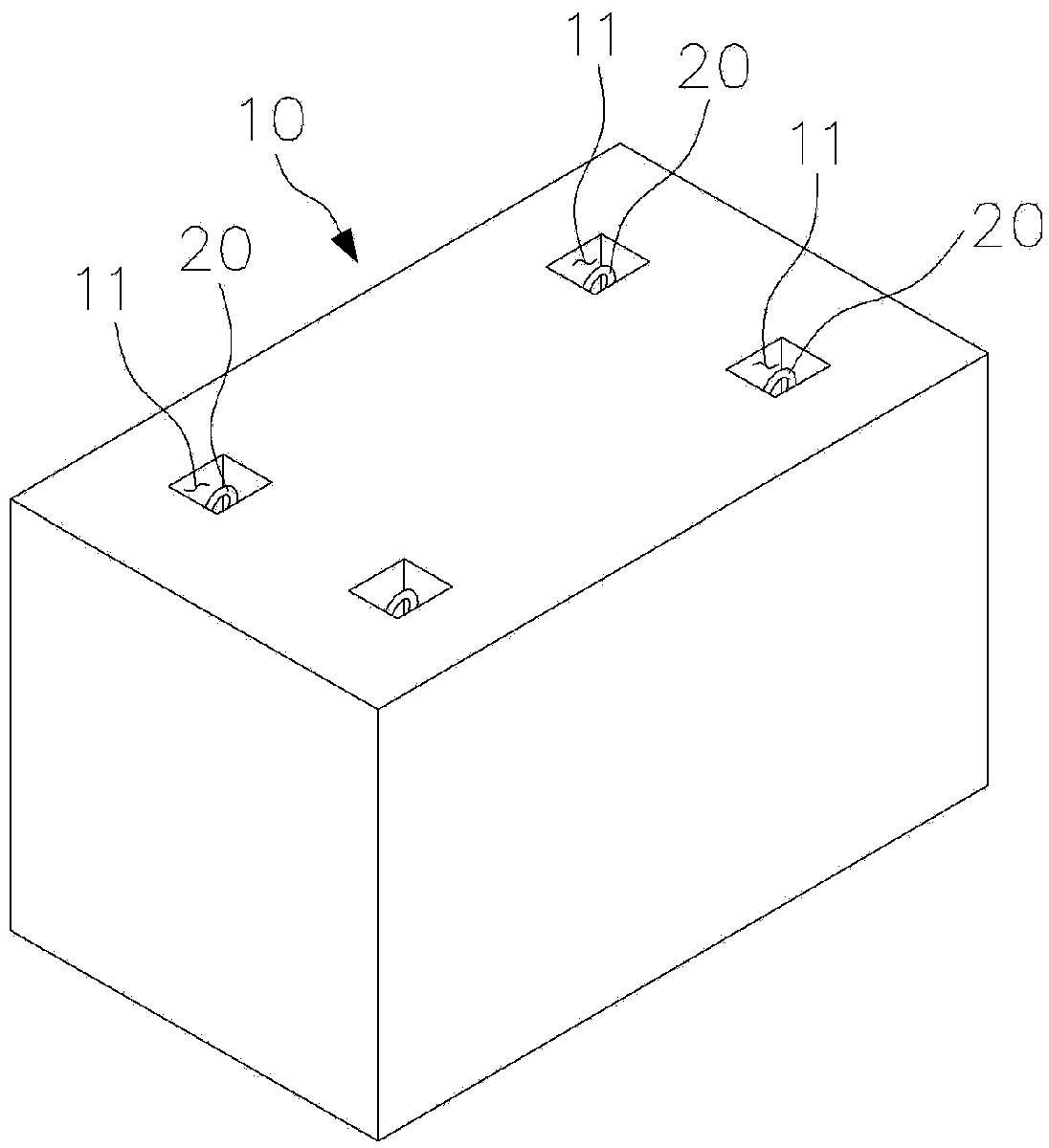

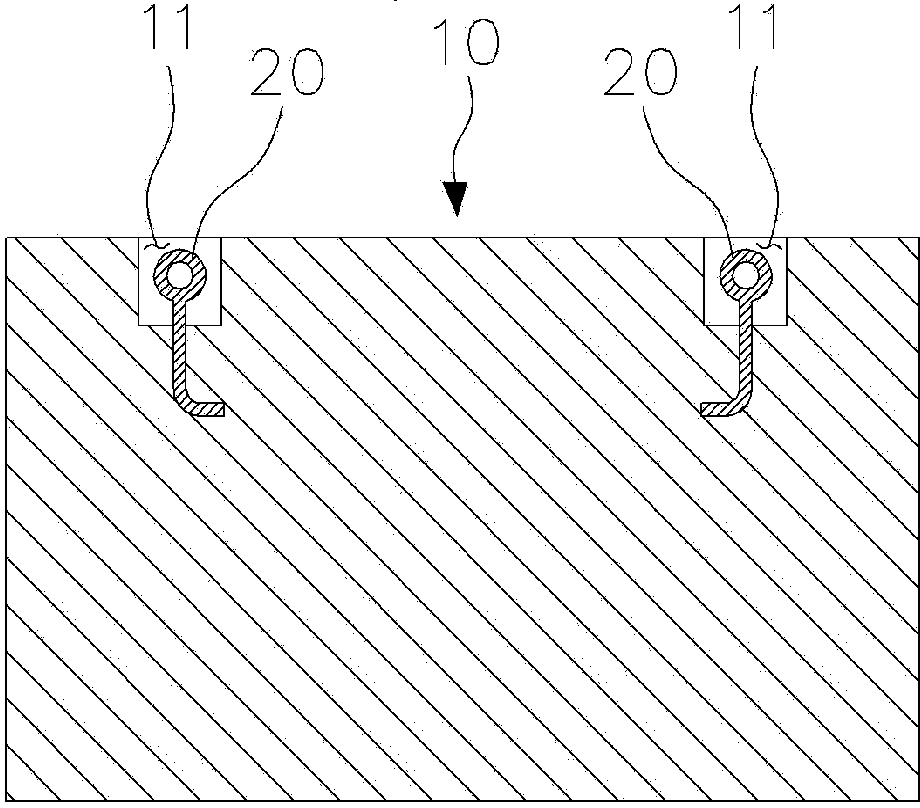

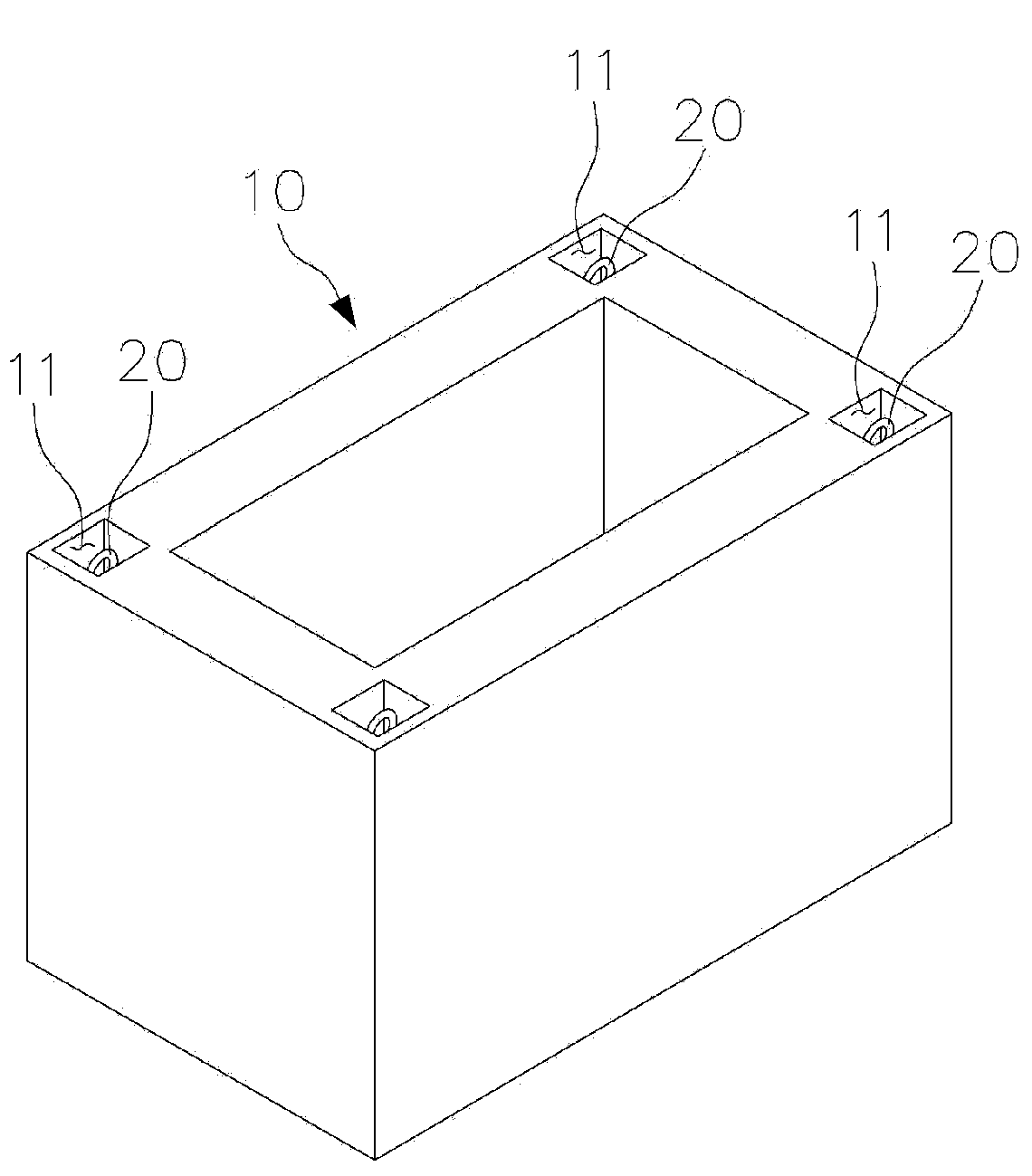

[0051] First, refer to Figure 4 and Figure 5 A large concrete block lifted by a crane according to a first embodiment o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com