Copper steel composite material for seawater enclosing aquaculture fishing net and manufacturing method for copper steel composite material

A composite material and colonization technology, applied in the field of metallurgy, can solve the problems of anti-biofouling, corrosion resistance and alloy strength, and achieve significant technological progress, cost reduction, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

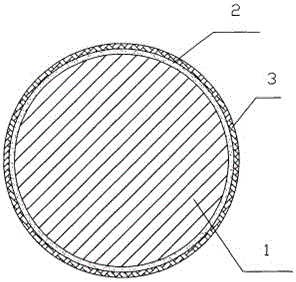

[0018] Such as figure 1 As shown, the present invention provides a copper-steel composite material for seawater enclosure fishing nets. The outer layer is a copper alloy layer 3, the core is steel 1, and the middle is a glued layer 2. The copper alloy layer 3 The thickness is 1-3mm, the mass percentage of copper in the copper alloy layer 3 is at least 70%, the strength of the steel 1 is greater than or equal to 600MPa, and the material of the bonding layer 2 is epoxy resin or phenolic resin, the thickness of the adhesive layer 2 is 10-30 μm.

[0019] The present invention also provides the above-mentioned method for preparing a copper-steel composite material for seawater enclosure fishing nets, comprising the following steps:

[0020] 1) Degreasing and pickling the steel material 1 as the core, and then applying glue 2 on the outer periphery of the steel material 1;

[0021] 2) Wrap the copper alloy 3 with a thickness of 1-3mm on the outer periphery of the steel material 1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com