Coal mine explosion-proof frequency converter

An explosion-proof frequency converter and coal mine technology, applied in the field of frequency converter, can solve the problems of low system response speed, large heat dissipation fin spacing, small specific heat capacity of refrigerant, etc., and achieve the effects of rapid heat transfer, high heat dissipation efficiency, and reduced heat attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

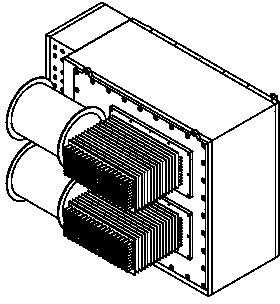

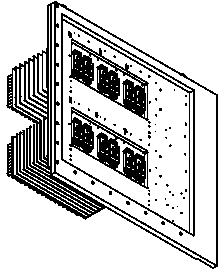

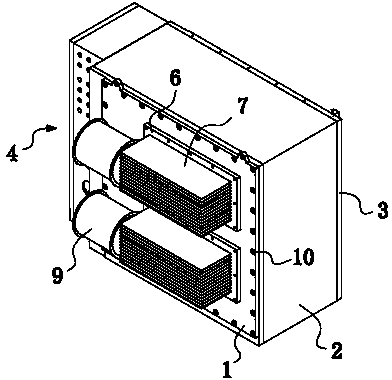

[0033] Such as image 3 , 4 , 5, and 6, an explosion-proof frequency converter for coal mines includes an explosion-proof housing 4 composed of a housing rear plate 1, a housing maintenance frame 2 and a door body 3, and the rectification power is set in the explosion-proof housing 4 Unit 5, the housing rear plate 1 is provided with a radiator substrate 6 that partially extends into the explosion-proof casing 4, the rectifier power unit 5 is fixed on the radiator substrate 6 extending into the explosion-proof casing 4, and the heat dissipation A plurality of heat dissipation fins 7 are arranged in parallel on the outside of the heat sink substrate 6 extending outward from the heat sink substrate 6 , and heat dissipation gaps 8 are provided between each heat dissipation fin 7 .

[0034] In order to improve the heat dissipation effect and enhanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com