Thermodynamic closed loop desiccant rotor system and process

a desiccant rotor and closed-loop technology, applied in the direction of heating types, separation processes, domestic cooling apparatus, etc., can solve the problems of high energy consumption, achieve the effect of maximizing the interchangeable and recovered energy capacity and capacity, significantly improving efficiency and energy conservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

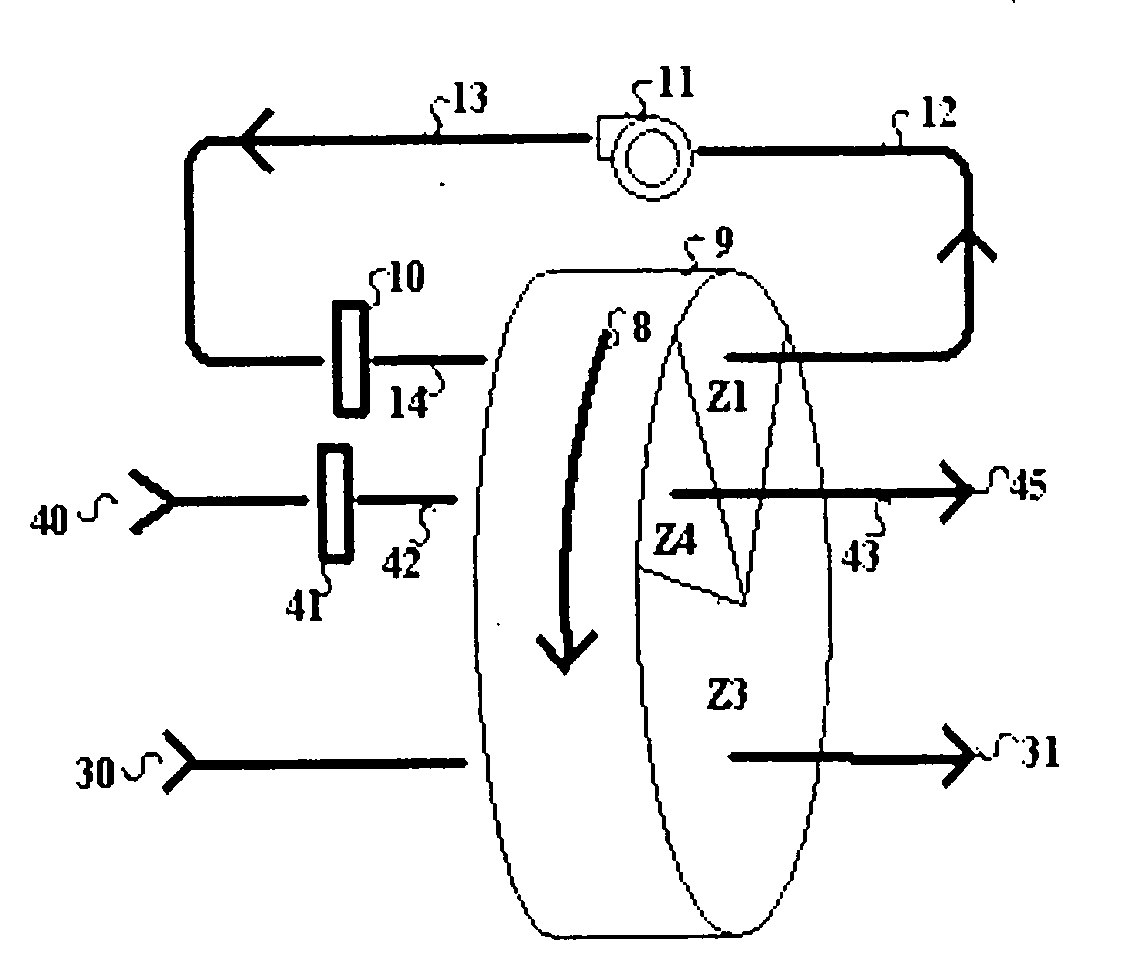

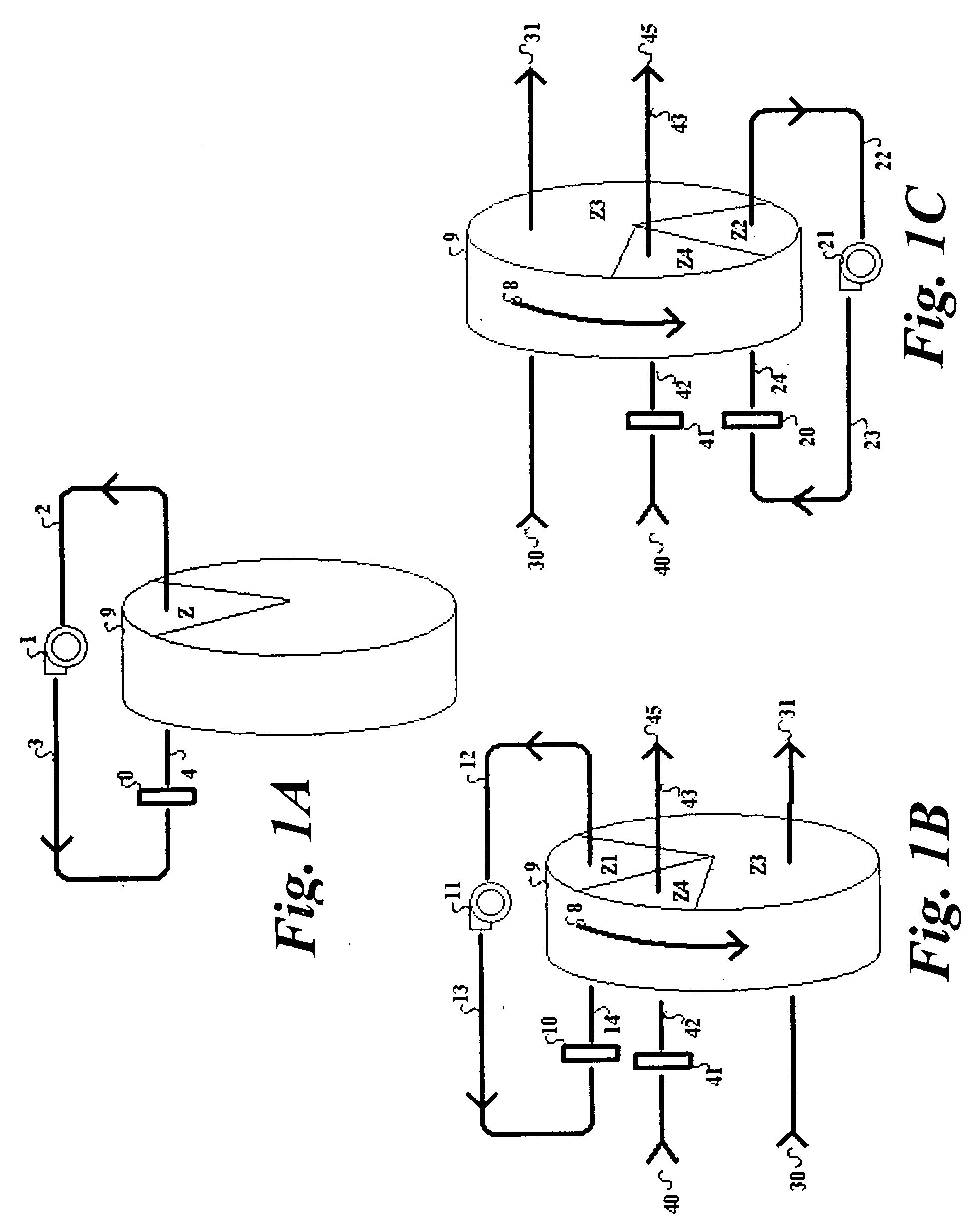

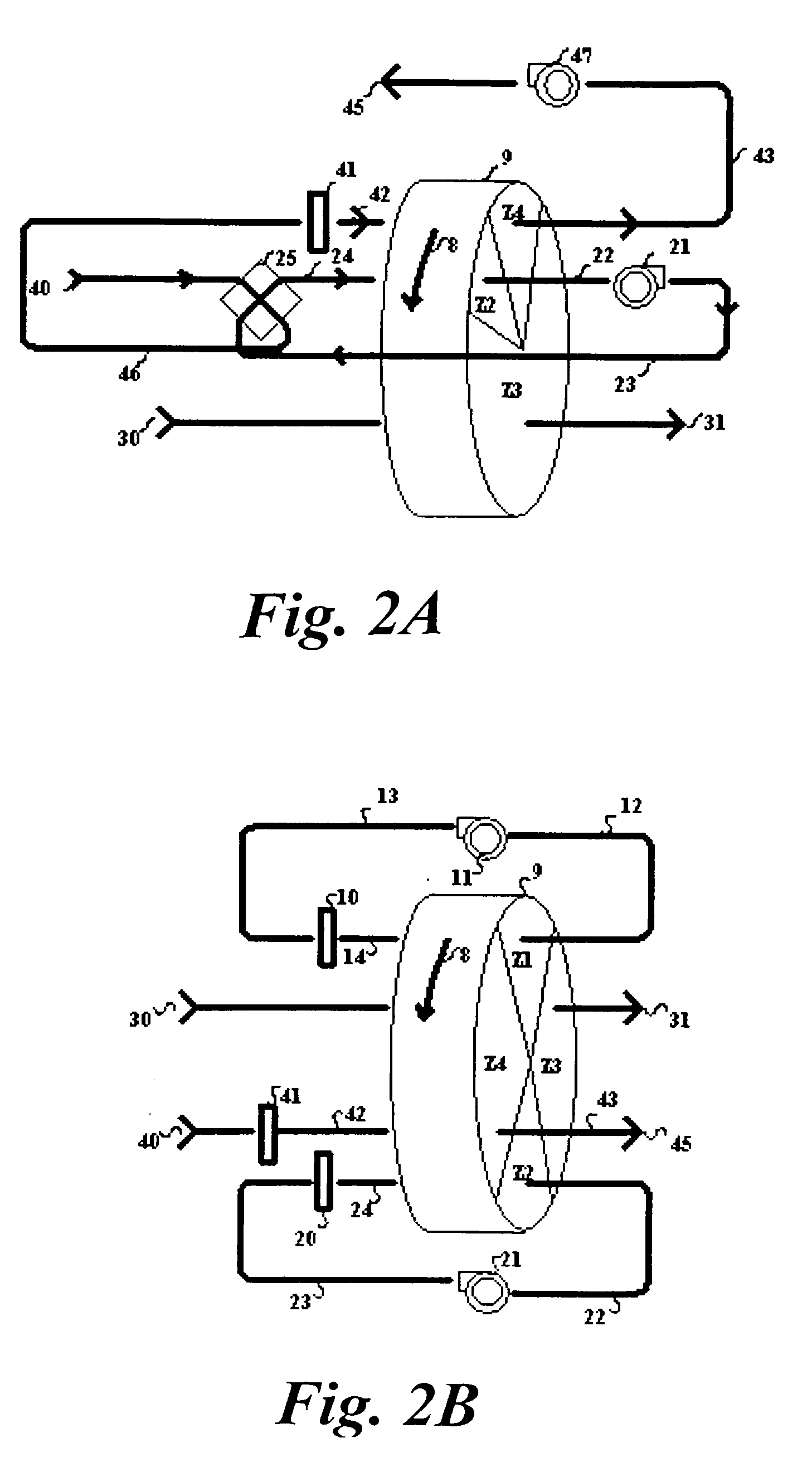

[0032]Detailed descriptions of several preferred embodiments are provided herein having arrangements of components and desiccant rotors with zoning features for carrying out various processes. It is to be understood, however, that the present invention may be embodied in various forms and combinations. Therefore, specific details disclosed herein are not to be interpreted as limiting, but rather as a basis for the claims and as a representative basis for teaching one skilled in the art to employ the present invention in virtually any appropriately detailed system, process, structure or manner.

[0033]As used herein, the term “air conditioning” is a general term meaning a system for controlling the temperature and humidity of air and other gases and includes dehumidification, humidification, and moisture release. Air conditioning systems for treating or conditioning and gases may include, for example, such systems as cooling systems, heating systems, gas separators, gas concentrators, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com