Flexible true stone paint and preparation method thereof

A real stone paint, flexible technology, applied in the field of architectural decorative coatings, can solve the problems of easy cracking of the paint film, poor stain resistance, insufficient toughness, etc., to improve hydrophobic performance, excellent crack resistance, promote plastic flow and elastic deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

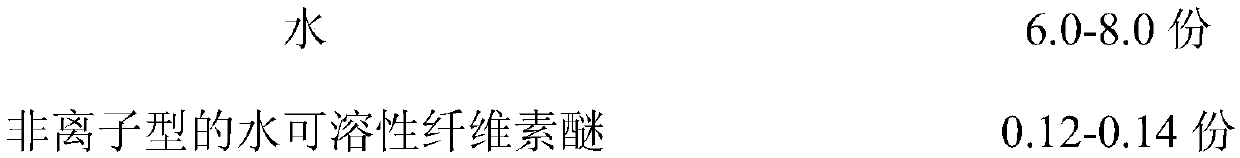

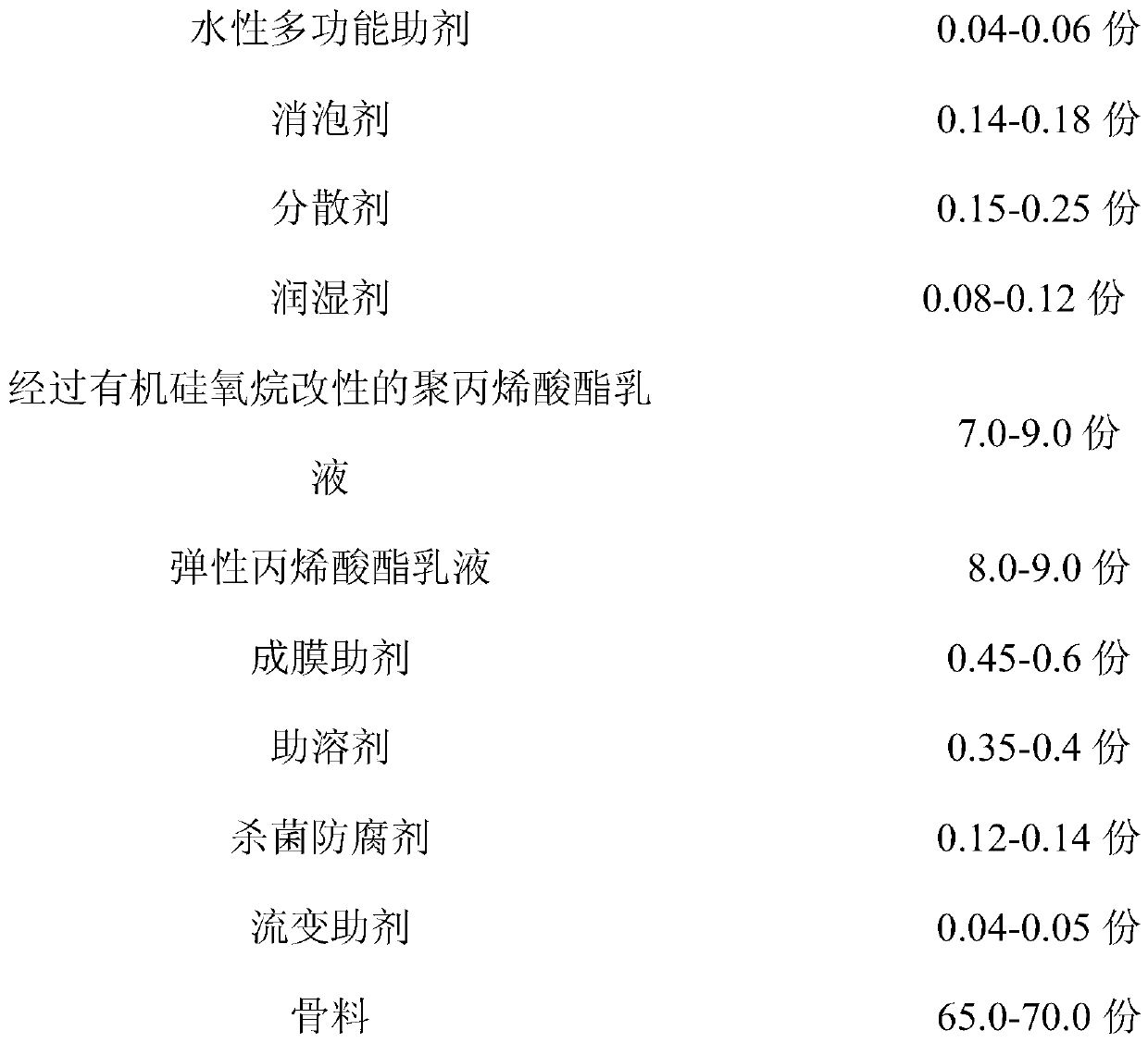

[0035] A kind of flexible real stone paint, it is formulated by the following components in weight ratio:

[0036]

[0037] The preparation method of this flexible genuine stone paint, it comprises the following steps carried out in sequence:

[0038] ①Under stirring at a speed of 700r / min, add non-ionic water-soluble cellulose ether into the deionized water, and stir for 4 minutes, and continue to add 2-amino-2-methyl-1 with a mass concentration of 95% while stirring. -The aqueous solution of propanol, then increase rotating speed to 900r / min and stir 8min;

[0039] ② Add oil-based defoamer, polyacrylic acid sodium salt dispersant, non-ionic surfactant, dimethyl silicon, etc. to the mixture prepared in step ① sequentially while stirring at a rotating speed of 900r / min. Oxane emulsion, surface treated highly dispersed nano-scale titanium dioxide and silica sol with hydroxyl groups, and then dispersed for 8 minutes;

[0040] ③Add polyacrylate emulsion modified by organosil...

Embodiment 2

[0043] A kind of flexible real stone paint, it is formulated by the following components in weight ratio:

[0044]

[0045]

[0046] The preparation method of this flexible genuine stone paint, it comprises the following steps carried out in sequence:

[0047] ①Under stirring at a speed of 500r / min, add non-ionic water-soluble cellulose ether to ordinary tap water, and stir for 5 minutes, and continue to add 2-amino-2-methyl- The aqueous solution of 1-propanol, then increase the rotating speed to 800r / min and stir for 10min;

[0048] ②Add organic silicon defoamer, ammonium polyacrylate dispersant, wetting agent, powder type water repellent, Nano-TiO 2 and silica sol, then dispersed for 0min;

[0049] ③Add organosiloxane-modified polyacrylate emulsion, elastic acrylate emulsion, film-forming aids, co-solvents, and the remaining silicone to the mixture prepared in step ② while stirring at a speed of 800r / min. Defoamer, bactericidal preservative and rheological additive, ...

Embodiment 3

[0052] A kind of flexible real stone paint, it is formulated by the following components in weight ratio:

[0053]

[0054]

[0055] The preparation method of this flexible genuine stone paint, it comprises the following steps carried out in sequence:

[0056] ①Under stirring at a speed of 750r / min, add non-ionic water-soluble cellulose ether into the water, and stir for 3 minutes, then add 2-amino-2-methyl-1-propane with a mass concentration of 90% while stirring Alcohol aqueous solution, then increase the rotating speed to 1000r / min and stir for 5min;

[0057] ②Add emulsion-type defoamer, dispersant, wetting agent, organosilicon water-repellent, and nano-TiO to the mixture prepared in step ① sequentially while stirring at a speed of 1000r / min. 2 and silica sol, and then dispersed for 5 minutes;

[0058] ③Add organosiloxane-modified polyacrylate emulsion, elastic acrylate emulsion, film-forming aids, co-solvents, and remaining emulsion type to the mixture prepared in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com