Anti-exposure eucalyptus laminated wood veneer and production method thereof

A production method and veneer technology, applied in the joining of wooden veneers, wood processing appliances, manufacturing tools, etc., can solve the problems of harming consumers' health, increasing the amount of formaldehyde released, and increasing the amount of glue applied, and achieve the finished product size High stability, reduced formaldehyde emission, and the effect of overcoming resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

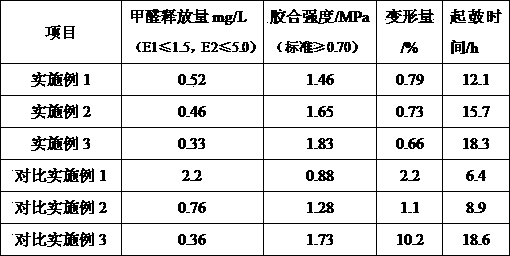

Embodiment 1

[0015] Manually select eucalyptus veneers of the same size, apply urea-formaldehyde resin adhesive, the amount of glue is 300g / ㎡, and form 5 layers of blanks. The first cold pressing is at room temperature and the pressure is 1.5MPa. Hot pressing, the temperature is 115-120 °C, and the pressure is 2 MPa; 60-80 °C constant temperature room for 5-8 hours; the constant temperature room is ventilated and naturally cooled, heat dissipation for 3-4 hours; the second cold pressing, the temperature is room temperature, The pressure is 1.5MPa, the second hot pressing, the temperature is 110-115°C, and the pressure is 2MPa; the second time is to keep in a constant temperature room, the temperature is 60-80°C, the time is 90-120min, and the constant temperature room is ventilated and cooled naturally , heat dissipation and health preservation for 3 to 4 hours; the third cold pressing, the temperature is normal temperature, and the pressure is 1.5MPa, the third hot pressing, the temperatur...

Embodiment 2

[0017] Manually select eucalyptus veneers of the same size, apply urea-formaldehyde resin adhesive purchased on the market, the glue amount is 250g / ㎡, and form 9 layers of blanks. The first cold pressing is at room temperature and the pressure is 1.8MPa. , the first hot pressing, the temperature is 115-120°C, and the pressure is 2.5MPa; 60-80°C constant temperature room for 5-8 hours; the constant temperature room is ventilated and naturally cooled, heat dissipation for 3-4 hours; the second cold pressing , the temperature is normal temperature, the pressure is 1.8MPa, the second hot pressing, the temperature is 110-115°C, and the pressure is 2.5MPa; the second time is to keep in a constant temperature room, the temperature is 60-80°C, and the time is 90-120min , the constant temperature room is ventilated to cool down naturally, heat dissipation and health preservation for 3-4 hours; the third cold pressing is at room temperature and the pressure is 1.8MPa, the third hot press...

Embodiment 3

[0019] Manually select eucalyptus veneers of the same size, apply urea-formaldehyde resin adhesive purchased on the market, the glue amount is 200g / ㎡, 15 layers of blanks are assembled, the first cold pressing is at room temperature, and the pressure is 2.0MPa , the first hot pressing, the temperature is 115-120°C, and the pressure is 3MPa; the 60-80°C constant temperature room is kept for 5-8 hours; The temperature is normal temperature, the pressure is 2.0MPa, the second hot pressing, the temperature is 110-115°C, and the pressure is 3MPa; the second time is to keep in a constant temperature room, the temperature is 60-80°C, the time is 90-120min, and the temperature is constant. The room is ventilated to cool down naturally, heat dissipation and health preservation for 3-4 hours; the third cold pressing is at room temperature and the pressure is 2.0MPa, the third hot pressing is at 120-125°C and the pressure is 3MPa, and it is polished with coarse sand and fine sandpaper Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com