Medical degradable antibacterial composite material as well as preparation method and application thereof

A technology of composite materials and polymer materials, which is applied in bone defect repair surgery, bone trauma surgery, medical degradable antibacterial composite materials and its preparation method and application, and medical devices for plastic surgery. It can solve the problem of non-degradable absorption and poor effect Too ideal, lower mechanical strength and other problems, to overcome the effects of excessively high acidity, controllable degradation and absorption speed, and controllable degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

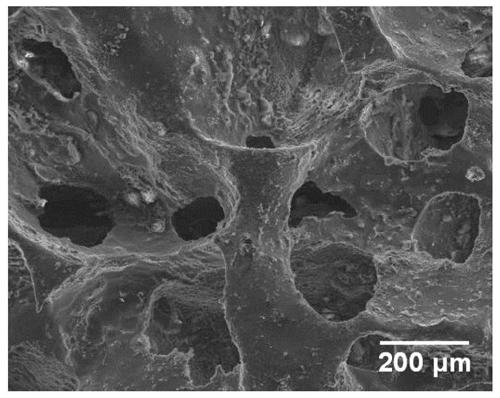

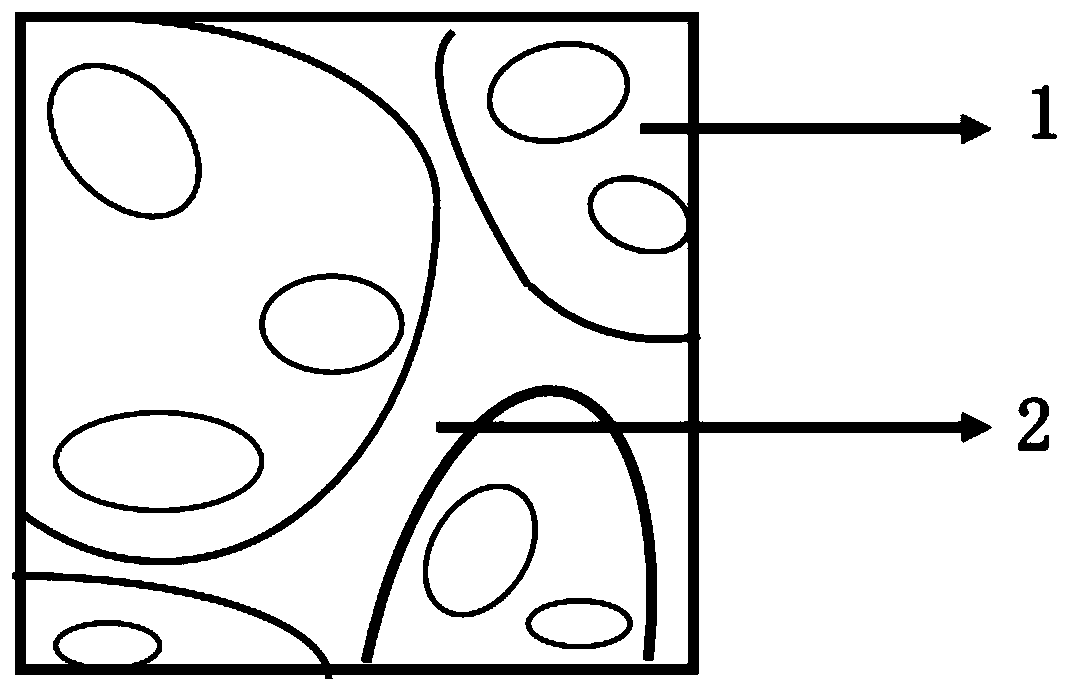

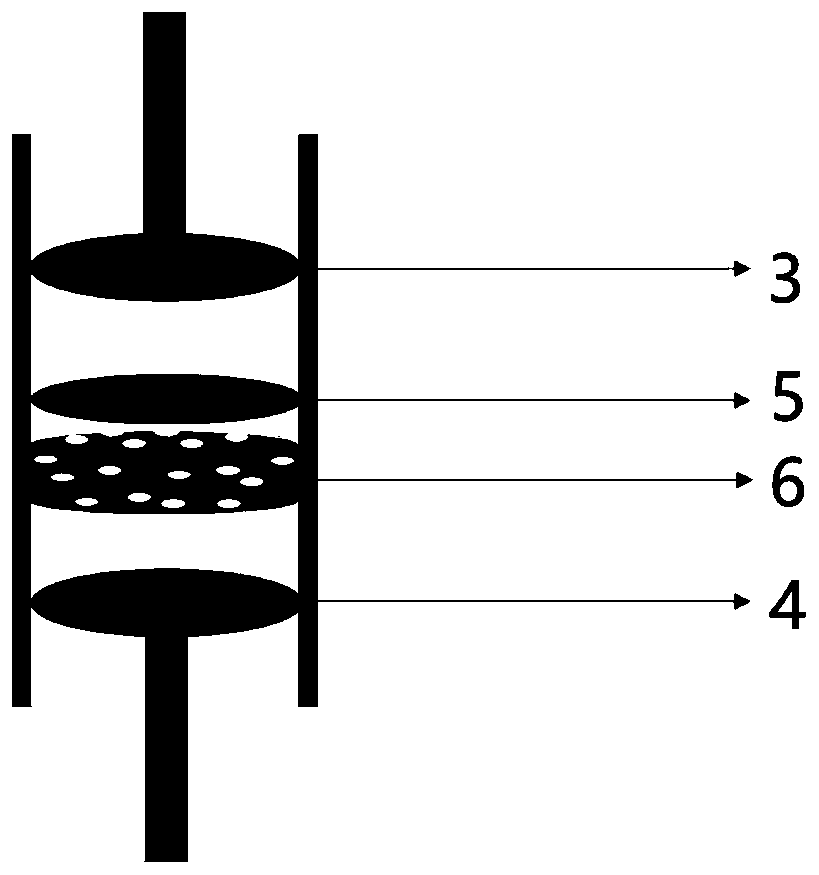

[0032] A medical biodegradable antibacterial composite material. The composite material uses ZX20 (97.7wt%Mg, 2wt%Zn, 0.3wt%Ca) porous magnesium alloy 6 with through-holes as a reinforcement (porosity 40%, pore size 200μm ) The holes 1 communicate with each other, the shape of the hole body is circular, the thickness of the porous magnesium material is 0.5mm, and the holes 1 of the reinforcement body are filled with degradable polymer materials polycaprolactone and polylactic acid, of which polylactic acid accounts for the high 10% of the volume of the molecular material, polycaprolactone accounts for 90% of the total volume of the polymer material, and the degradable polymer material is uniformly dispersed with nano-magnesium oxide powder. In the composite material, the degradable polymer material accounts for 19% of the total volume of the composite material, the porous magnesium alloy 6 accounts for 80% of the total volume of the composite material, and the nano-magnesium oxi...

Embodiment 2

[0041] A medical degradable antibacterial composite material, the composite material has through-holes AZ31 (96wt%Mg, 3wt%Al, 1wt%Zn) porous magnesium alloy 6 as a reinforcement (porosity 85%, pore size 3000μm, pores 1 are connected with each other, the shape of the pore body is polygonal, the thickness of the porous magnesium material is 5mm, and the holes of the reinforcement body 1 are filled with the degradable polymer materials polycaprolactone and polylactic acid. Polylactic acid accounts for 90% of the volume of the polymer material. %, polycaprolactone occupies 10% of the total volume of the polymer material, and nano-magnesium oxide powder is uniformly dispersed in the degradable polymer material. The degradable polymer material in the composite material accounts for 49% of the total volume of the composite material, porous Magnesium alloy 6 accounts for 50% of the total volume of the composite material, and nano-magnesium oxide powder accounts for 1% of the total volum...

Embodiment 3

[0050] A medical degradable antibacterial composite material, the composite material uses Mg2Zn (98wt%Mg, 2wt%Zn) porous magnesium alloy 6 with through-holes as a reinforcement (porosity: 50%, pore size: 400μm) and pores 1 communicate with each other , The shape of the pore body is polygonal or circular, the thickness of the porous magnesium material is 2mm, and the hole 1 of the reinforcement body is filled with the degradable polymer material polycaprolactone and polylactic acid, which accounts for 30% of the volume of the polymer material Polycaprolactone occupies 70% of the total volume of polymer materials, and nano-magnesium oxide powder is uniformly dispersed in the degradable polymer material. The degradable polymer material in the composite material accounts for 29.5% of the total volume of the composite material. Porous magnesium Alloy 6 accounts for 70% of the total volume of the composite material, and nano-magnesium oxide powder accounts for 0.5% of the total volume...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com