3D laser carving high-toughness UV type PVD finish paint

A flexible and laser engraving technology, applied in the field of chemical coatings, can solve the problems of poor paint film effect, UV topcoat can not be laser engraved, one hundred grid difference bending flying paint, etc., to achieve excellent ring test performance, artificial resistance Sweaty hands and improved flexibility

Active Publication Date: 2018-07-20

YIXING HONGTAI CHEM

View PDF3 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Solve the problem that the existing UV topcoat cannot be laser engraved, the laser engraving is cracked, the paint film layer behind the laser engraving is not effective, and the problem of bending and flying paint is poor.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

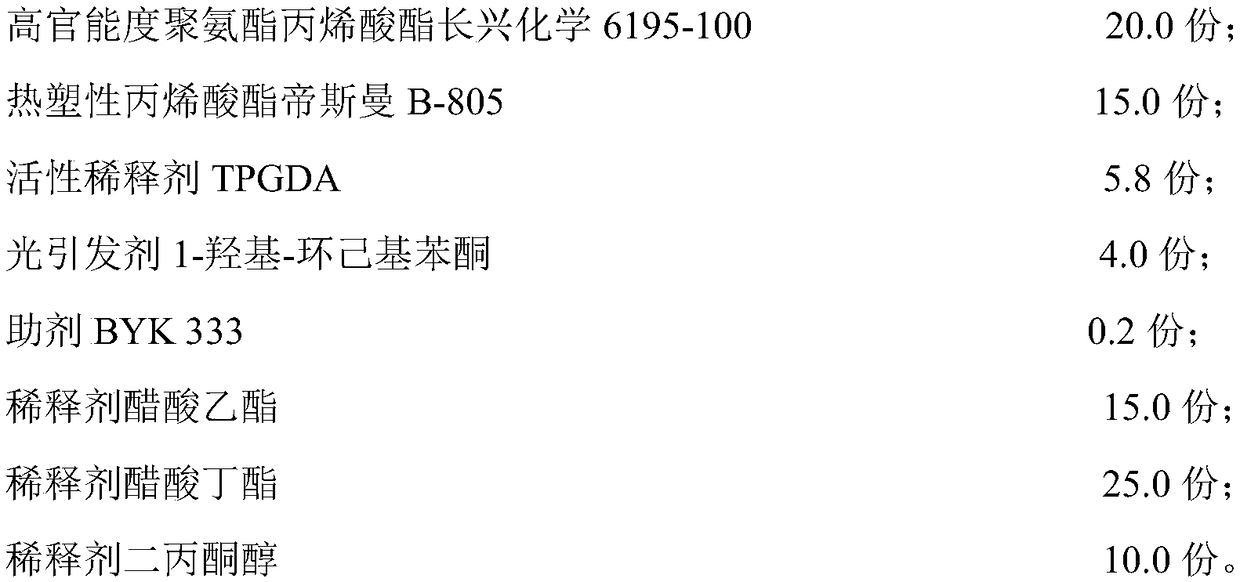

Embodiment 1

[0035] Example 1: Formulation

[0036]

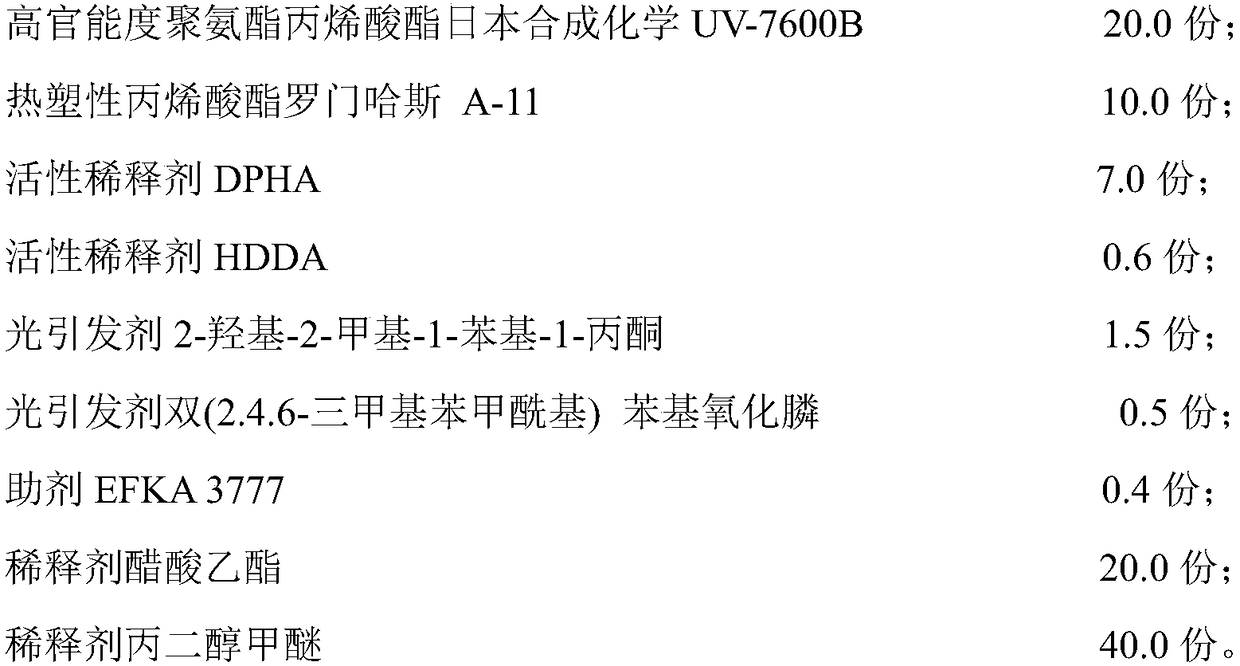

Embodiment 2

[0037] Example 2: Formulation

[0038]

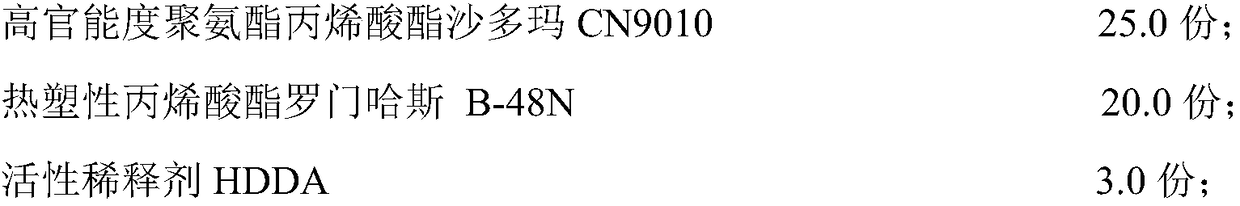

Embodiment 3

[0039] Embodiment 3: formula

[0040]

[0041]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to 3D laser carving high-toughness UV type PVD finish paint, which is mainly prepared from the following ingredients in parts by weight: 5 to 35 parts of high-functionality urethane acrylate, 5 to 30 parts of thermoplastic acrylate, 1 to 10 parts of reactive diluent, 0.1 to 5.0 parts of photoinitiators, 0.1 to 0.6 part of auxiliary agents and 35 to 80 parts of diluents. The finish paint provided by the invention effectively solves the wide universal problems that the paint adhesion and the toughness of the UV light curing vacuum film plating paint are low, and the matching of the primer of the UV light curing vacuum film plating paint and finish paint in the PU color paint is poor, and the like. The finish paint provided by the invention has a good protection effect and very high flexibility; an obtained paint film has the characteristics of high toughness, high bending performance, excellent annular testing performance and yellowing resistance performance and thelike. Meanwhile, the finish paint has the characteristics that the operation is convenient; the construction is simple; the normal temperature curing is realized; the applicability is wide, and the like. the appearance effect and the service life of the electronic product are effectively improved.

Description

technical field [0001] The invention belongs to the field of chemical coatings, in particular to a 3D radium-carved high-flexibility UV-type PVD topcoat. The topcoat can be used for surface decoration or protection of vacuum coating workpieces of electronic products such as mobile phones, digital cameras, and tablet computers. Background technique [0002] With the development of plastic decoration technology, most of the original plastic products are extrusion or compression molding. During the heating and extrusion process, volatile impurities in the raw materials may escape to the surface, forming more craters, and other microscopic defects. , leading to low surface gloss and poor aesthetics. In addition, most conventional plastic parts are wear-resistant, solvent-resistant, low-performance, easy to scratch, fog, and surface damage. Therefore, it is necessary to decorate the surface of plastic parts and protection. It is formed by using a plastic substrate to coat a pri...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D175/14C09D133/04

CPCC09D133/04C09D175/14C08L33/04C08L75/14

Inventor 陈朝岚吴玉民周明伟吴刚强郭猛刘晓明卢礼灿

Owner YIXING HONGTAI CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com