Water-based pressure-sensitive adhesive for polyethylene protective film and preparation method thereof

A polyethylene protective film and pressure-sensitive adhesive technology, which is applied in adhesives, graft polymer adhesives, film/sheet adhesives, etc., can solve the problems of users' health hazards and environmental pollution, and achieve Excellent performance, low energy consumption, excellent high temperature and high humidity resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

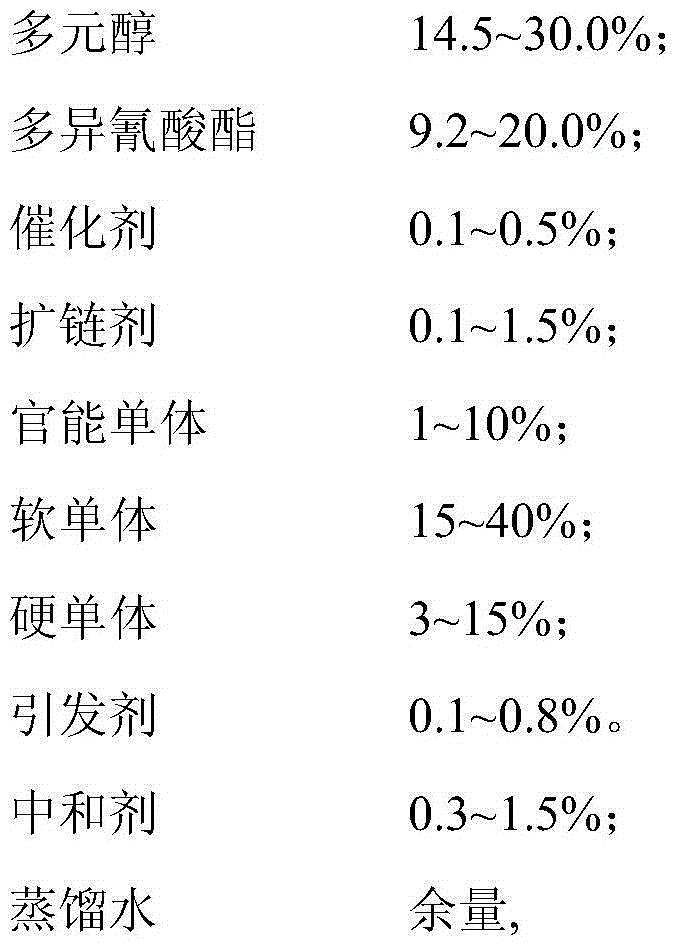

Method used

Image

Examples

Embodiment 1

[0055] 1. Synthetic PUA emulsion

[0056]After dehydrating 100g of polyoxypropylene diol and 50g of polyoxypropylene triol under reduced pressure, add 100g of diphenylmethane diisocyanate, 0.5g of stannous octoate, and 0.5g of di-n-butyltin dilaurate, at 80-85°C React for 2 hours, add 0.5g of ethylenediamine, add 100g of hydroxyethyl acrylate after 1 hour of heat preservation reaction, react for 1 hour, cool down to 45-50°C, add 3g of N,N-diethylethylamine, 0.5g of dimethylol Propionic acid, 80g butyl acrylate, 70g ethyl acrylate, 30g methyl acrylate, 20g methyl methacrylate, 437g distilled water, stirred for 0.5-1 hour, added 8g of azobisisobutyronitrile, and reacted at 80°C for 3 Hours, after cooling, filter to obtain PUA emulsion (polyurethane / acrylate composite emulsion).

[0057] 2. Preparation of water-based pressure-sensitive adhesive

[0058] Stir 95g of PUA emulsion and 5g of polymethylene polyphenyl polyisocyanate evenly at room temperature to obtain the water-base...

Embodiment 2

[0075] 1. Synthetic PUA emulsion

[0076] After dehydrating 145g of polyoxypropylene triol by vacuum distillation, add 55g of diphenylmethane diisocyanate, 37g of toluene diisocyanate, 1.5g of triethylenediamine, 1g of di-n-butyltin dilaurate, and react at 80-85°C for 2 1 hour, add 0.5g dimethylolpropionic acid, keep warm for about 1 hour, then add 35g hydroxyethyl acrylate, react for about 1 hour, cool down to 45-50°C, add 15g N,N-diethylethylamine, 0.5g Dimethylolpropionic acid, 320g butyl acrylate, 80g isooctyl acrylate, 75g methyl acrylate, 75g methyl methacrylate, 158g distilled water, stirred for 0.5-1 hour, added 1.5g azobisisobutyronitrile, in React at 80°C for about 3 hours, filter after cooling to obtain PUA emulsion.

[0077] 2. Preparation of water-based pressure-sensitive adhesive

[0078] 98g of PUA emulsion, 1g of polymethylene polyphenyl polyisocyanate, and 1g of 4,4-dimethylmethane-diisocyanate were evenly stirred at room temperature to obtain the water-base...

Embodiment 3

[0091] 1. Synthetic PUA emulsion

[0092] After 300g of polyoxypropylene triol is distilled and dehydrated under reduced pressure, add 200g of toluene diisocyanate, 2g of stannous octoate, and 3g of di-n-butyltin dilaurate, react at 80-85°C for 2 hours, add 5g of ethylenediamine, and keep warm for the reaction After about 1 hour, add 5g of hydroxyethyl acrylate and 5g of N-methylolacrylamide, react for about 1 hour, cool down to 45-50°C, add 4g of N,N-diethylethylamine, 10g of dimethylolpropionic acid, 120g butyl acrylate, 130g isooctyl acrylate, 30g methyl acrylate, 185g distilled water, stir for 0.5-1 hour, add 1g azobisisobutyronitrile, react at 80°C for about 3 hours, cool and filter to obtain PUA lotion.

[0093] 2. Preparation of water-based pressure-sensitive adhesive

[0094] Stir 99.9g of PUA emulsion and 0.1g of 4,4-dimethylmethane-diisocyanate evenly at room temperature to obtain the water-based pressure-sensitive adhesive of the present invention.

[0095] 3. De...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com