A processing method for obtaining high corrosion resistance and ultra-thick galvanized layer for power fittings

A technology of electric power fittings and processing methods, applied in metal material coating process, hot dipping process, coating and other directions, can solve the problems of inability to match the life of electric power facilities for more than 30 years, and the zinc layer cannot be made thick, so as to eliminate adhesion Low strength, good adhesion, good thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

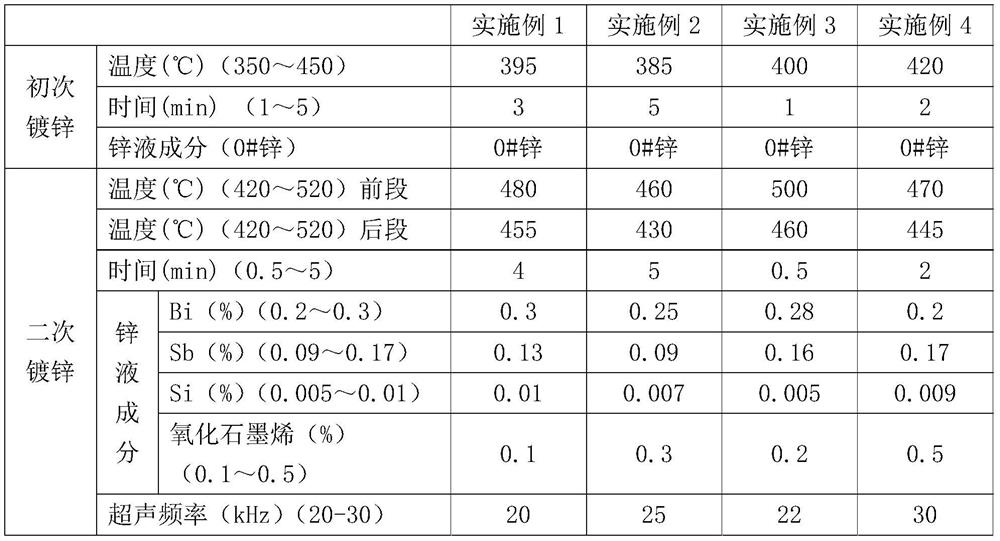

[0034] S1: Preliminary plating: place the pretreated workpiece in the primary galvanizing tank for initial plating for 3 minutes, and then take it out to dry, wherein the zinc solution in the primary galvanizing tank adopts 0# zinc, and the initial plating temperature is 395°C;

[0035] S2: Secondary galvanizing: The workpiece after primary galvanizing is placed in a rectangular secondary galvanizing pool for 4 minutes, then taken out to solidify and dry. 0.01% Si and 0.1% graphene oxide particles, the graphene oxide particles are porous graphene oxide nanoparticles, the secondary galvanizing temperature is 480 °C in the front section and 455 °C in the rear section, and the workpiece is sine wave up and down in the secondary galvanizing pool Ups and downs move forward, and at the same time, the ultrasonic wave is continuously vibrated, and the ultrasonic frequency is 20kHz.

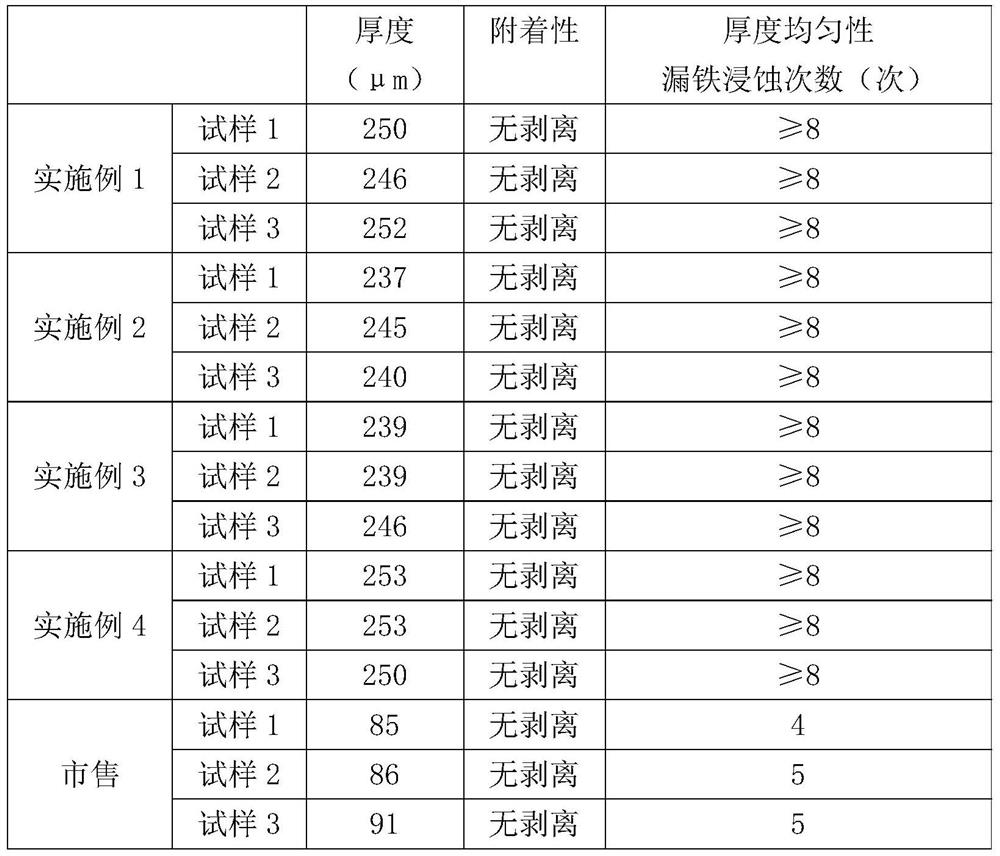

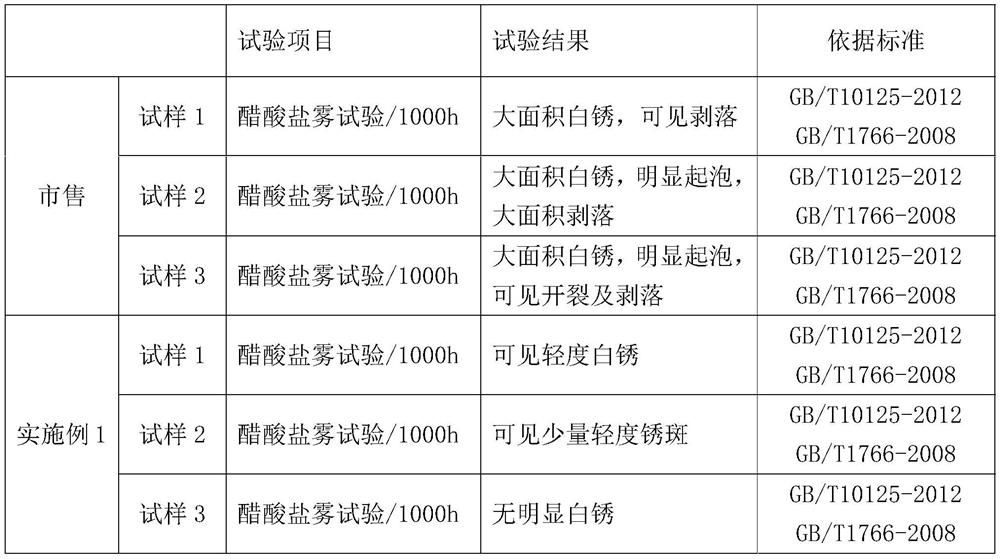

[0036] The steps of Examples 2 to 4 are the same as those of Example 1, except that the process parame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com