Method for preparing herbal biological fiber and biological paper pulp

A bio-fiber and herbal technology, applied in the field of herbal bio-fiber and bio-pulp preparation, can solve the problems of infeasibility, incomplete degumming, incomplete lignin decomposition, etc., to achieve sustainable development, reduce investment costs, The effect of shortening the preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

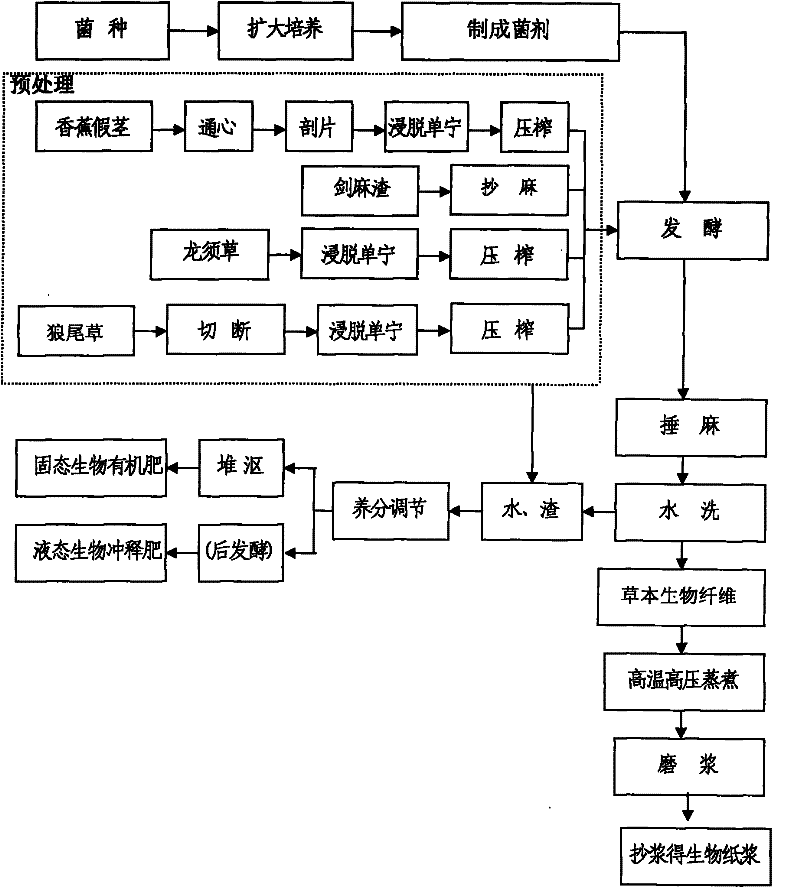

Method used

Image

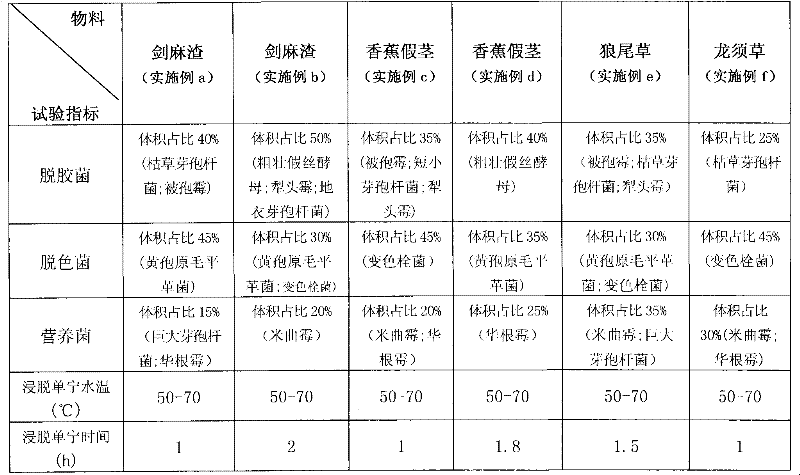

Examples

preparation example Construction

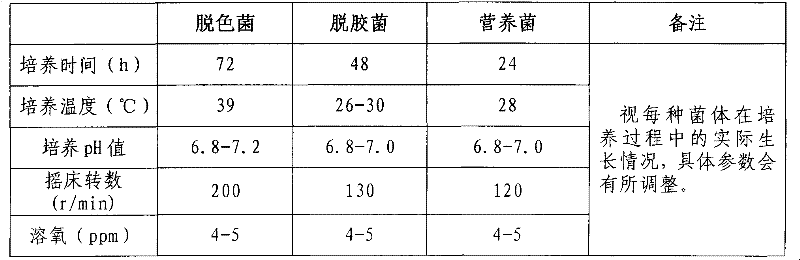

[0072] 1. Preparation of composite bacterial agent

[0073] Through a single strain fermentation experiment and multiple composite bacteria non-antagonistic cooperative fermentation experiments, the inventor finally screened out one or more of the aspergillus oryzae, Rhizopus chinensis, and Bacillus megaterium. Vegetative bacteria combination composed of various strains; Bacillus licheniformis, Bacillus Pumilus, Bacillus subtilis, Absidia, Mortierella, Candida stout Combination of degumming bacteria consisting of one or more strains of yeast (Candida valida); decolorizing bacteria consisting of one or more strains of Trametes versicolor, Phanerochaete chrysosporium A complex microbial flora composed of multiple strains.

[0074] 1. Bacterial strain culture to make bacterial liquid

[0075] After the three bacterial groups were cultured by seeds, they were multiplied and multiplied in a conical flask with a constant temperature shaker. The culture time was 24 to 72 hours, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com