Continuous tea leaf vacuum drying fragrance extraction device and method

A vacuum drying and continuous technology, applied in tea drying, heating equipment, drying solid materials, etc., can solve the problems of easy loss of aroma, long time consumption, poor color of tea, etc., and achieve the effect of easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

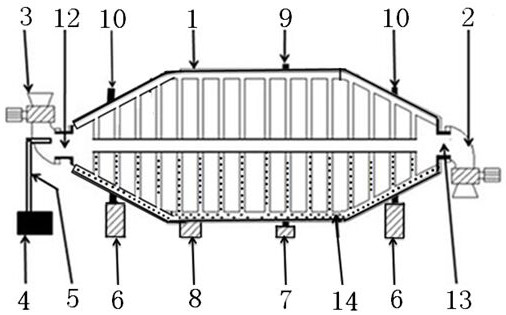

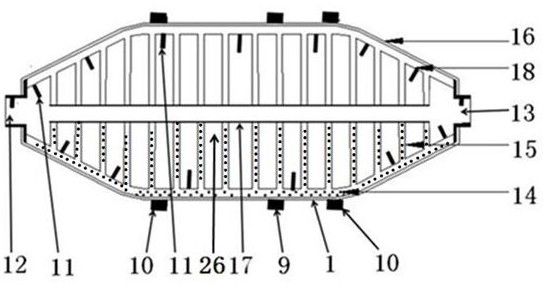

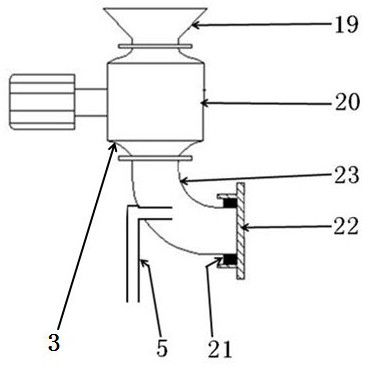

[0055] Such as figure 1 , figure 2 , image 3 , Figure 4 The shown continuous tea vacuum drying and aroma enhancing device includes a drum bin 1, feeding equipment 3, discharging equipment 2, driving device 7, vacuum unit 4, support roller 6, air guide pipe 5, raceway 10, gear ring 9. Heating device 8.

[0056] The described drum bin 1 is a single-drum drum bin.

[0057] A gear ring 9 is installed on the drum bin 1 , a raceway 10 is installed on the drum bin 1 , and the supporting roller 6 supports the raceway 10 on the drum bin 1 .

[0058] The driving device 7 is used to drive the gear ring 9 on the drum bin 1, the gear ring 9 on the drum bin 1 is driven by the driving device 7, and the drum bin 1 is driven by the driving device 7 on the supporting wheel 6 Carry out rotary motion; the drum bin 1 rotates 2 times per minute.

[0059] The drive device 7 is a variable speed motor.

[0060] Such as figure 1 , figure 2 The drum bin 1 shown includes a heating bin 16 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com