Tea vacuum drying, aroma improving and cooling device and method

A vacuum drying and cooling device technology, applied in tea drying, heating devices, drying solid materials, etc., can solve the problems of time-consuming, laborious, single, and energy-consuming cooling of tea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

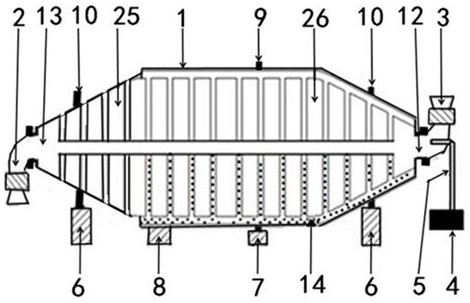

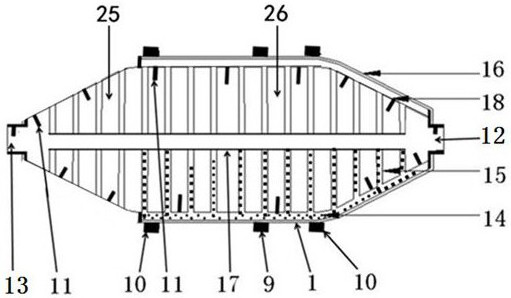

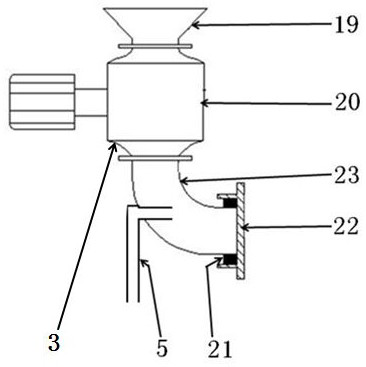

[0065] Such as figure 1 , figure 2 , image 3 , Figure 4 The shown cooling device for tea vacuum drying and aroma enhancement includes a drum bin 1, feeding equipment 3, discharging equipment 2, a driving device 7, a vacuum unit 4, a support wheel 6, an air duct 5, a raceway 10, and a gear ring 9 , Heating device 8.

[0066] A gear ring 9 is installed on the drum bin 1 , a raceway 10 is installed on the drum bin 1 , and the supporting roller 6 supports the raceway 10 on the drum bin 1 .

[0067]The driving device 7 is used to drive the gear ring 9 on the drum bin 1, and the drum bin 1 rotates on the supporting wheel 6 under the drive of the driving device 7; the drum bin 1 rotates 2 times per minute.

[0068] The drive device 7 is a variable speed motor.

[0069] Such as figure 1 , figure 2 The drum bin 1 shown includes a heating bin 16 , a drying bin 18 for extracting fragrance, and a heat-conducting working medium 14 .

[0070] The storehouse body of described dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com