A continuous black tea production line that simultaneously produces multiple tea shapes

A production line and technology of black tea, applied in the direction of tea treatment before extraction, etc., can solve the problems of difficulty in making different types of black tea, imprecise classification, single tea shape, etc., and achieve good taste consistency, good screening effect, and high tea aroma Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

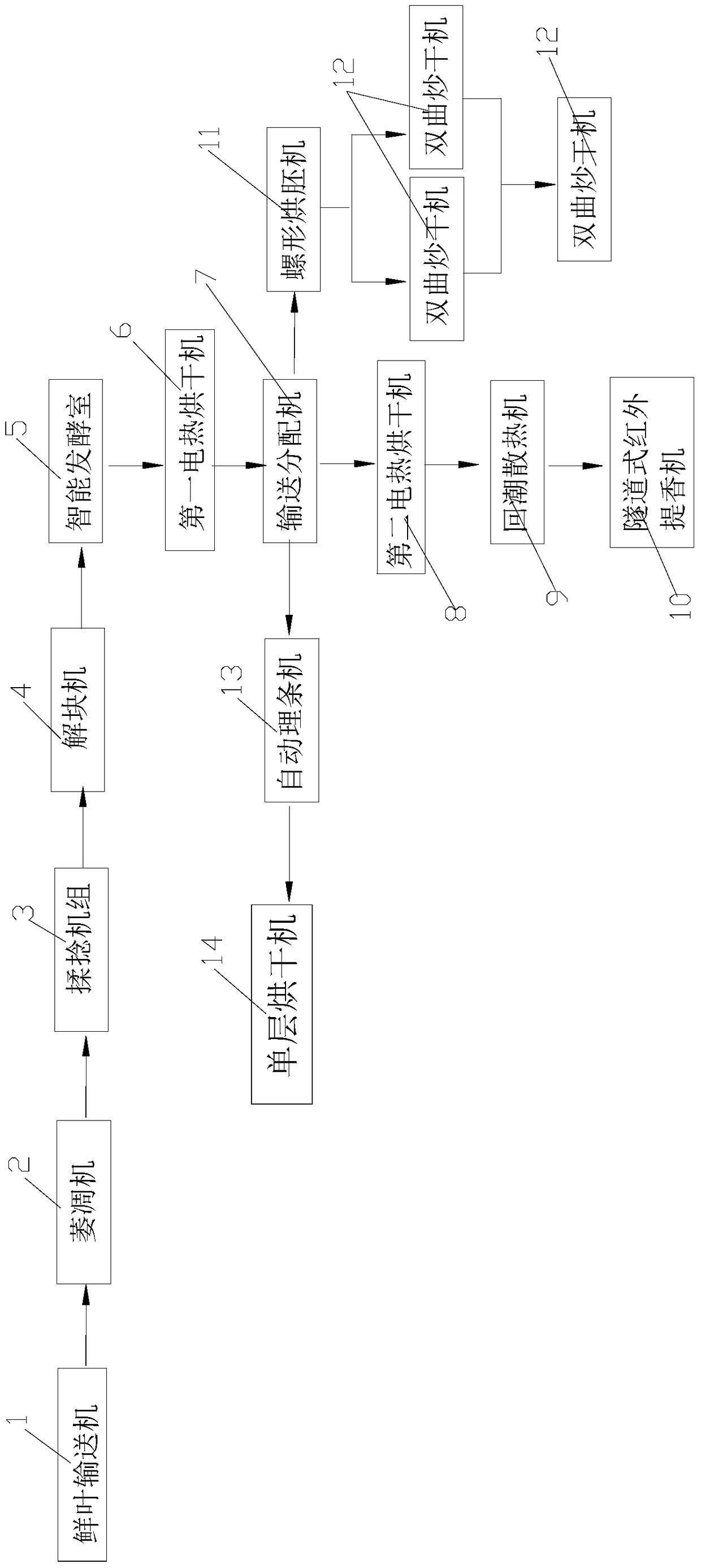

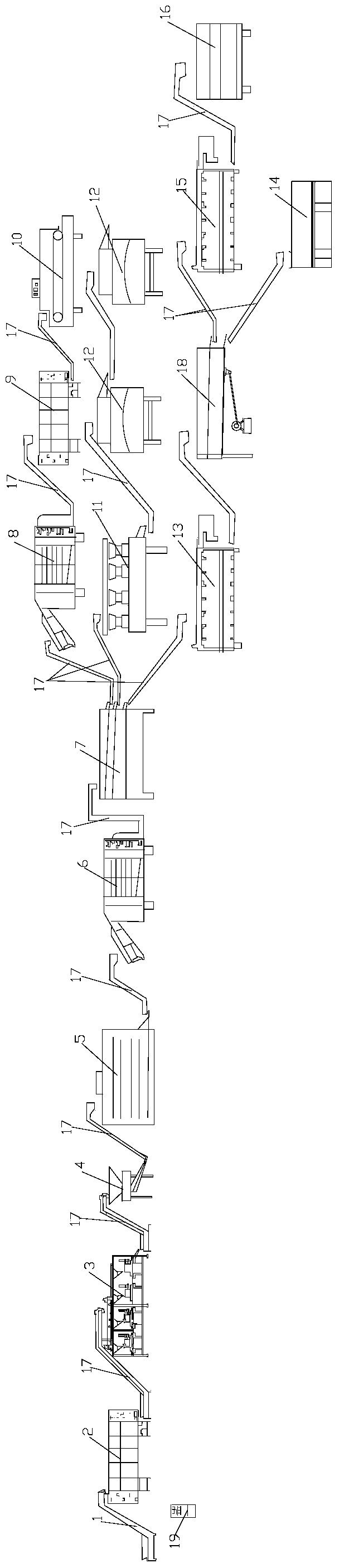

[0030] A continuous black tea production line that produces multiple tea shapes at the same time, such as figure 1 , 3As shown in 7, it includes the fresh leaf conveyor 1 that transports the fresh leaves to the withering machine 2, and the discharge port of the withering machine 2 transports the tea leaves to the top of the rolling unit 3 through the elevator 17, so that the tea leaves enter the rolling machine for rolling . The discharge conveyor belt below the kneading unit 3 transports the kneaded tea leaves to the feed hopper of the deblocking machine 4 through the hoist 17 . The tea leaves are deblocked by the deblocker 4, and the outlet of the deblocker 4 is connected with the intelligent fermentation chamber 5 through the elevator 17, and the tea leaves are transported to the intelligent fermentation chamber 5 for fermentation. The discharge port of the fermentation chamber 5 is connected with the first electric heating dryer 6 through the hoist 17, and the fermented ...

Embodiment 2

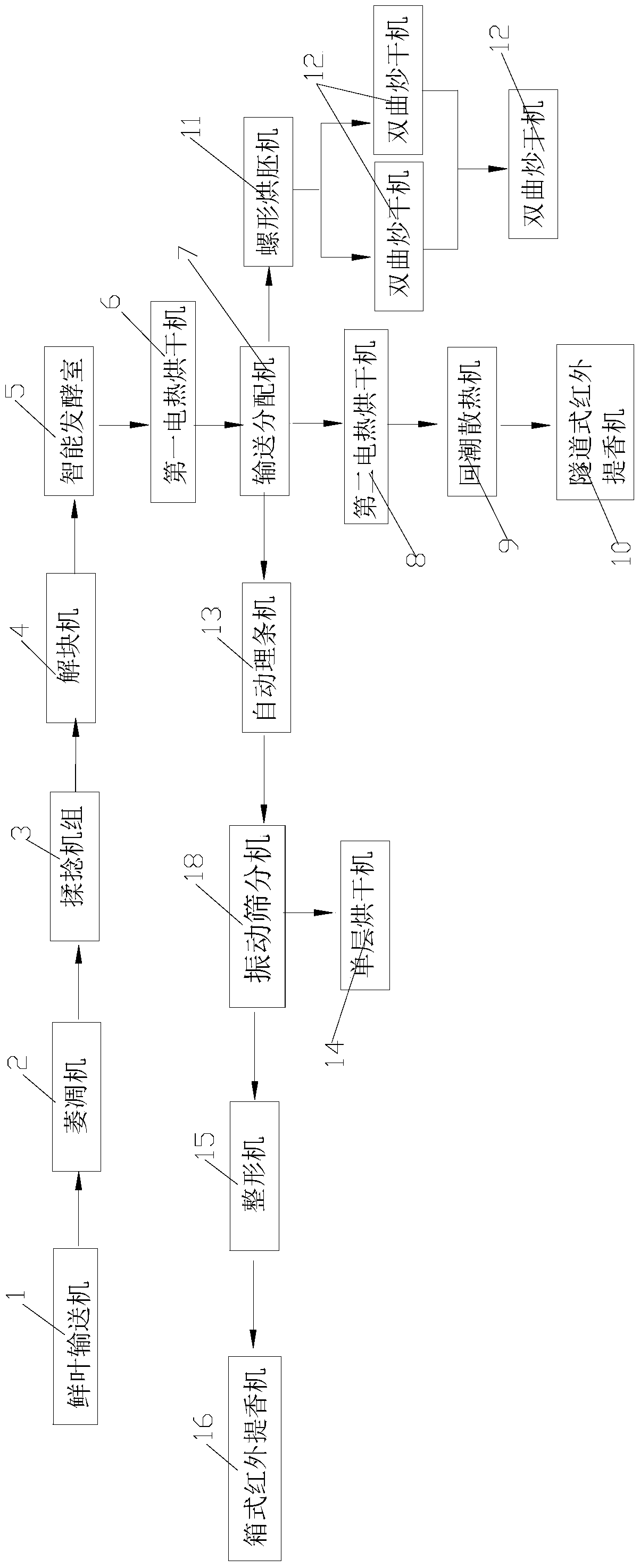

[0049] Such as Figures 2 to 7 As shown, a continuous black tea production line that produces multiple tea shapes at the same time, a third screen 73 is also provided below the second screen 72, and the number of meshes of the third screen 73 is 18 meshes. A screen 71, a second screen 72, and a third screen 73 divide the conveying and distributing machine from top to bottom into the first layer, the second layer, the third layer, and the lower four layers, and each layer is provided with a discharge port ; The outlet of the fourth layer is connected with the accessory tea collecting device.

[0050]The discharge opening of described automatic strip pruning machine 13 is connected with vibratory screening machine 18 by elevator 17, and the screen mesh of vibratory screening machine 18 is 10 orders, and vibratory screening machine 18 is all provided with discharge screen on the upper and lower floors of the screen. mouth. The tealeaves in the described automatic pruning machin...

Embodiment 3

[0052] Such as Figures 2 to 7 As shown, a continuous black tea production line that simultaneously produces multiple tea shapes, the deblocking machine 4 is provided with a vibrating screen, the mesh of the vibrating screen is 8 mesh, and the vibrating screen divides the deblocking machine 4 There are two upper and lower floors, and each layer is provided with a discharge port; at least two sets of fermentation platforms are arranged in the intelligent fermentation room 5, and the two discharge ports of the deblocking machine 4 are respectively connected to the intelligent fermentation chamber through the elevator 17. One group of fermentation platforms in the fermentation chamber 5 are connected and separated to ferment at different times.

[0053] The deblocking machine sieves the tea leaves into two stages while deblocking. Then it is transported to the intelligent fermentation room by the hoist for fermentation. The fermentation temperature and humidity conditions are th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com