Heating element for low-temperature cigarette and low-temperature cigarette

A heating body, low temperature technology, applied in the direction of smoker's supplies, applications, tobacco, etc., can solve the problems of inconsistent smoke taste, poor user experience, long waiting time, etc., to achieve good smoke taste consistency, fast smoke out, prevent hot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

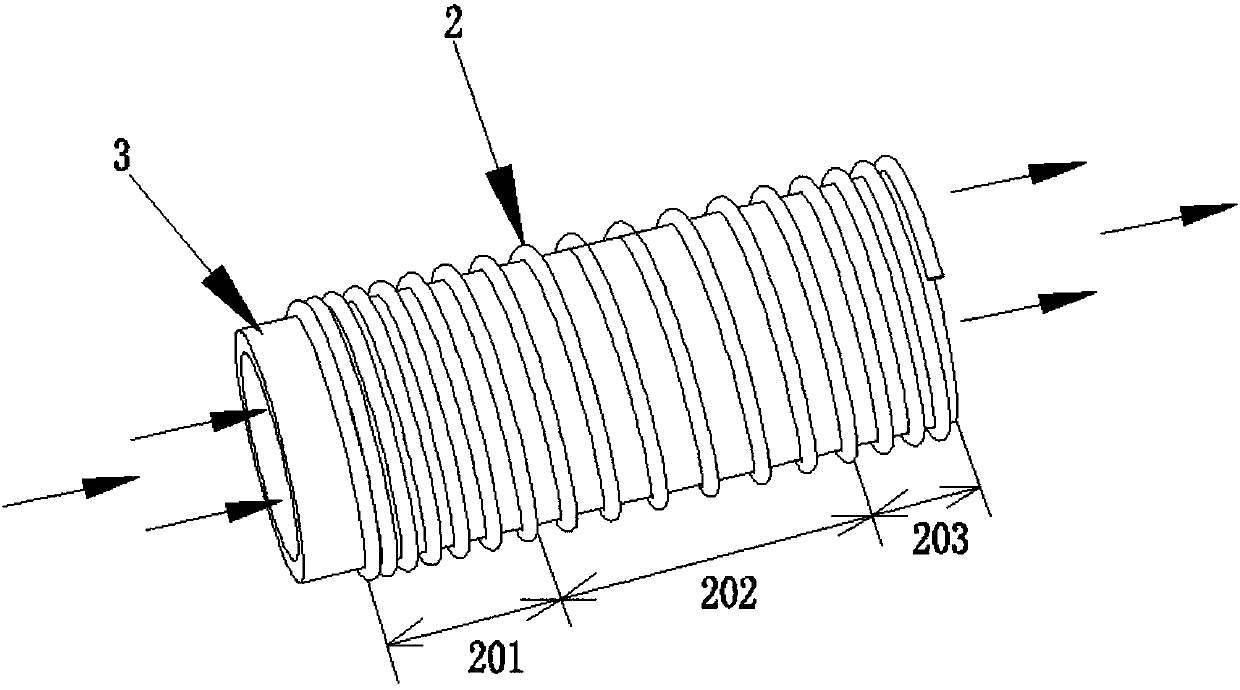

[0038] Such as figure 1 As shown, the heating element for low-temperature cigarettes includes a heating body 2 arranged along the length direction of the tobacco part 101 of the cigarette 1. The heating body 2 is composed of a first heating section 201 corresponding to the air intake section of the tobacco part 101 and corresponding to the middle section of the tobacco part 101. The second heating section 202 and the third heating section 203 corresponding to the air outlet section of the tobacco part 101 are sequentially connected; along the length direction of the tobacco part 101, the heating power of the second heating section 202 to the unit volume of tobacco is P.

[0039] The heating power of the first heating section 201 to a unit volume of tobacco is (3-8)P, preferably (3-4)P, more preferably 3P.

[0040] The heating power of the third heating section 203 to a unit volume of tobacco is (1.5~4)P, preferably (2~3)P, more preferably 2P.

[0041] The length of the first ...

Embodiment 2

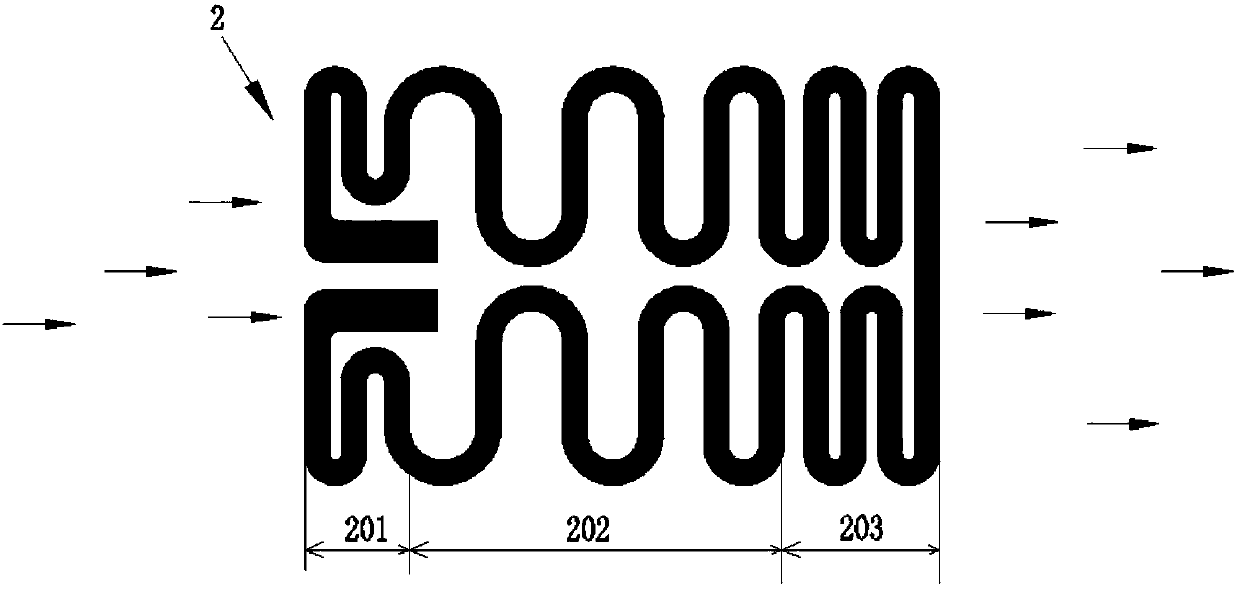

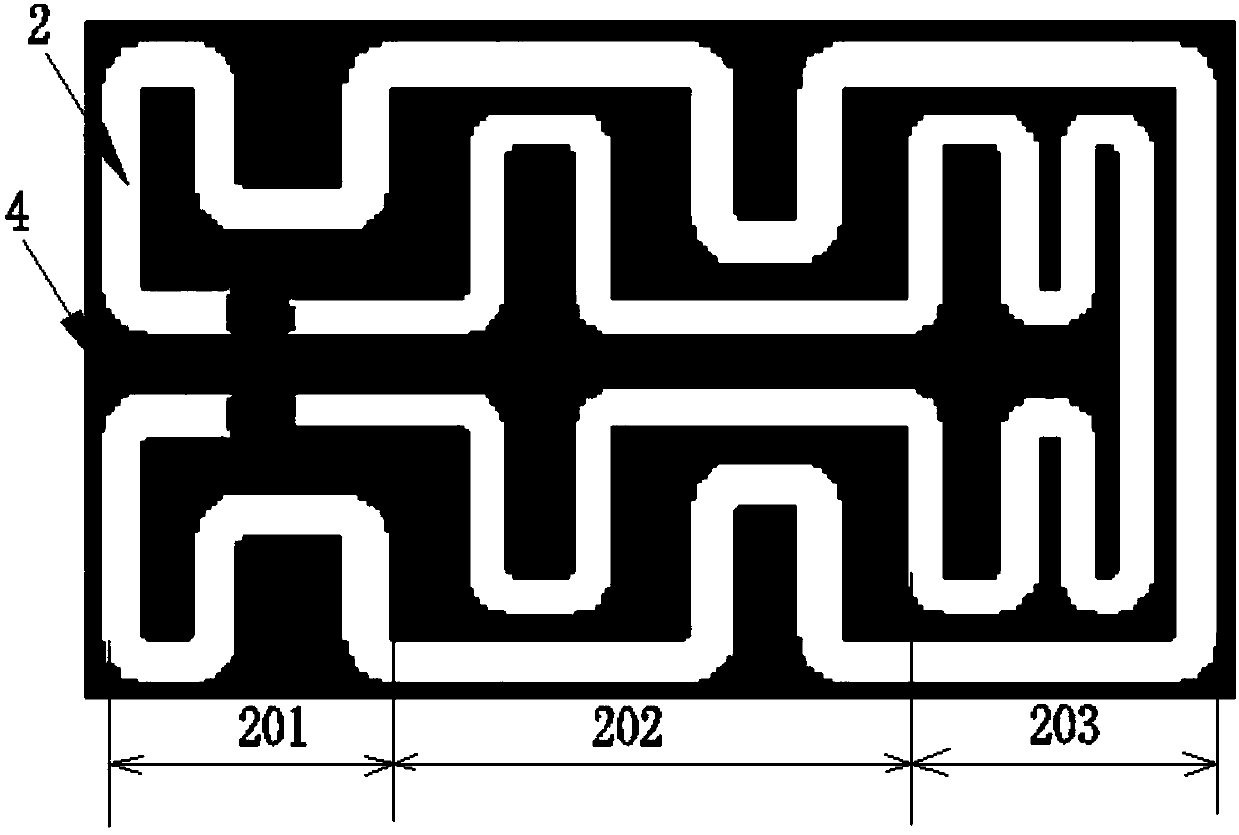

[0045] Such as figure 2 As shown, in Embodiment 2, the heating element for low-temperature cigarettes includes a heating body 2 arranged along the length direction of the tobacco part 101 of the cigarette 1, and the heating body 2 is composed of a first heating section 201 corresponding to the air intake section of the tobacco part 101, and a The second heating section 202 corresponding to the middle section of the tobacco part 101, and the third heating section 203 corresponding to the outlet section of the tobacco part 101 are sequentially connected; along the length direction of the tobacco part 101, the thermal power of the second heating section 202 to the unit volume of tobacco for P.

[0046] The heating power of the first heating section 201 to a unit volume of tobacco is (3-8)P, preferably (3-4)P, more preferably 3P.

[0047] The heating power of the third heating section 203 to a unit volume of tobacco is (1.5~4)P, preferably (2~3)P, more preferably 2P.

[0048] T...

Embodiment 3

[0052] Examples of Low Temperature Smoke

[0053] Such as Figure 4 to Figure 6 As shown, the low-temperature cigarette includes a cigarette 1 with a tobacco part 101, and also includes the heating element described in Embodiment 1. The heating body 2 is arranged along the length direction of the tobacco part 101 and heats the tobacco part 101 to generate smoke.

[0054] The tobacco part 101 is placed in the inner cavity of the heat transfer tube 3; the base 5 carrying the tobacco part 101 is provided at the bottom of the heat transfer tube 3, and the air passage 501 connecting the tobacco part 101 and the air intake channel 6 is opened on the base 5.

[0055] A first air storage cavity 7 communicating with the tobacco portion 101 and the air hole 501 is provided between the base 5 and the tobacco portion 101 .

[0056] The low-temperature smoke also includes an outer casing 8, the heating body 2 and the heat transfer tube 3 are fixed in the outer casing 8 through the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com