Vacuum drying device and method for tea fermentation

A vacuum drying device and tea fermentation technology, applied in tea drying, heating devices, drying solid materials, etc., can solve the problems of large temperature and humidity differences, hinder normal fermentation, high carbon dioxide concentration, etc., and achieve the effect of small fluctuations in temperature changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

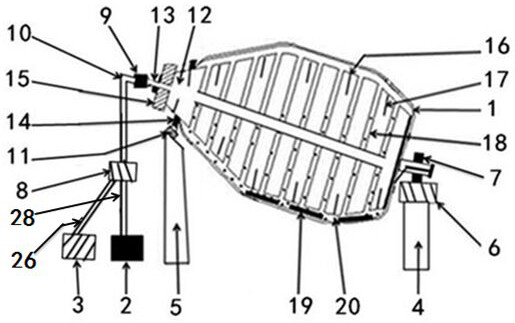

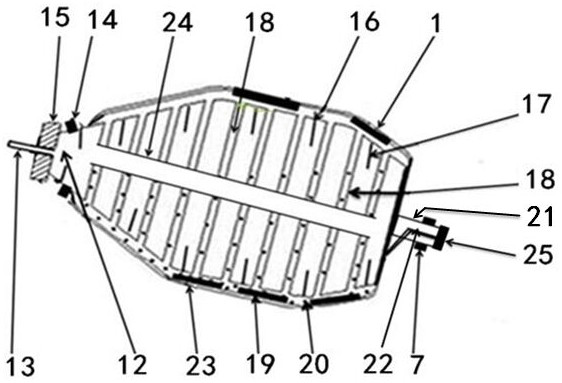

[0072] Such as figure 1 , figure 2 , image 3 The tea fermentation vacuum drying device shown includes a drum bin 1, an exhaust device 2, an oxygen device 3, a rear support 4, a front support 5, a driving device 6, a three-way valve 8, a dynamic sealing joint 9, an air guide pipe 10, Supporting wheel 11, oxygen delivery pipe 26, air extraction pipe 28.

[0073] The drum bin 1 includes a fermentation bin 16, a heating bin 23, a heat pipe 18, an electric heating device 19, a fixing bar 24, a sealing cover 15, a hollow transmission shaft 21, an exhaust pipe 13, a raceway 14, a spiral blade 17, Heat conduction working medium 20, gear 7, conductive ring 25.

[0074] The heating chamber 23 is wrapped on the outside of the fermentation chamber 16, and the joints between the chamber bodies at both ends of the heating chamber 23 and the chamber bodies at the two ends of the fermentation chamber 16 are fixed and sealed, and the fermentation chamber 16 and the heating chamber 23 are ...

Embodiment 2

[0115] Such as figure 1 , figure 2 The tea fermentation vacuum drying device shown includes a drum bin 1, an exhaust device 2, an oxygen device 3, a rear support 4, a front support 5, a driving device 6, a three-way valve 8, a dynamic sealing joint 9, an air guide pipe 10, Supporting wheel 11, oxygen delivery pipe 26, air extraction pipe 28.

[0116] The combined structure of the vacuum drying device for tea fermentation in Example 2 is the same as that of the vacuum drying device for tea fermentation described in Example 1, so the introduction will not be repeated here.

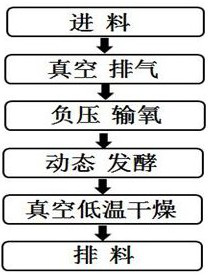

[0117] Such as figure 1 , figure 2 , Figure 4 The tea fermentation method shown includes feed, vacuum exhaust, negative pressure oxygen supply, dynamic fermentation, and discharge. The tea is fermented in 16 warehouses of the fermentation warehouse;

[0118] Step 1. Feeding: After the tea leaves to be processed are placed in the fermentation bin 16, the sealing cover 15 is installed.

[0119] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com