Full-automatic black tea fermentation device

A fermentation device, fully automatic technology, applied in the direction of tea processing before extraction, can solve the problems of inaccurate temperature control, inability to realize automatic control, etc., and achieve the effects of accurate temperature control, convenient production line, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

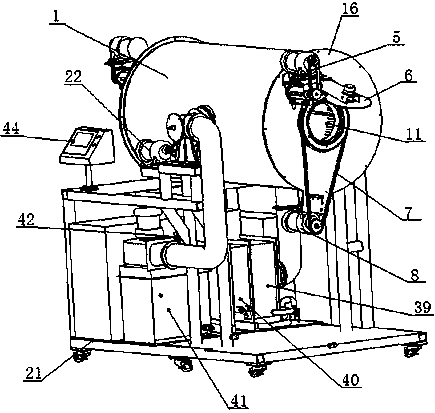

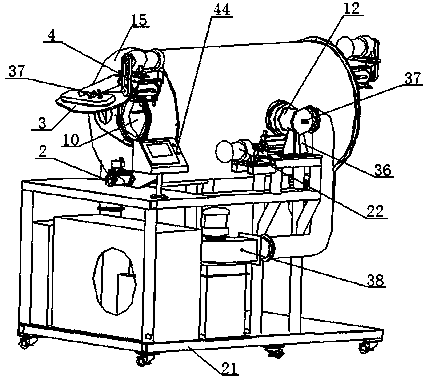

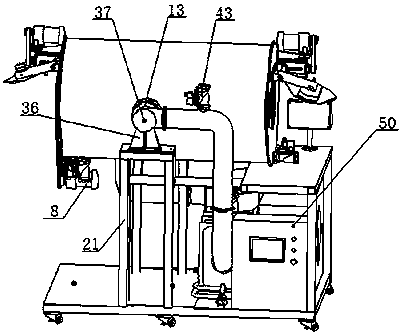

[0032] see Figure 1-Figure 9 , a fully automatic black tea fermentation device, comprising an outer cylinder 1, an inner cylinder 9, a frame 21, a rotating motor 8, a sprocket and a chain 7, the front end of the inner cylinder 9 is provided with a feed end 10, and the inner cylinder 9 The rear end is provided with a discharge end 11, the inner drum 9 is sleeved in the outer cylinder 1, the front end of the outer cylinder 1 is provided with a front cylinder cover 15, and the rear end of the outer cylinder 1 is provided with a rear cylinder cover 16. The end 10 is flush with the front cylinder cover 15, the discharge end 11 extends out of the rear cylinder cover 16, the outer circumference of the feed end 10 and the discharge end 11 is provided with bearings, and the outer ring of the bearing is provided with Bearing seat, the bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com