Organic-inorganic slow-released fertilizer and method for preparing same

A slow-release fertilizer and organic technology, applied in the field of slow-release fertilizer and its preparation, can solve the problems of not combining organic and inorganic fertilizers well, low processing efficiency, long composting cycle, etc. The effect of speeding up the melting process and easy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

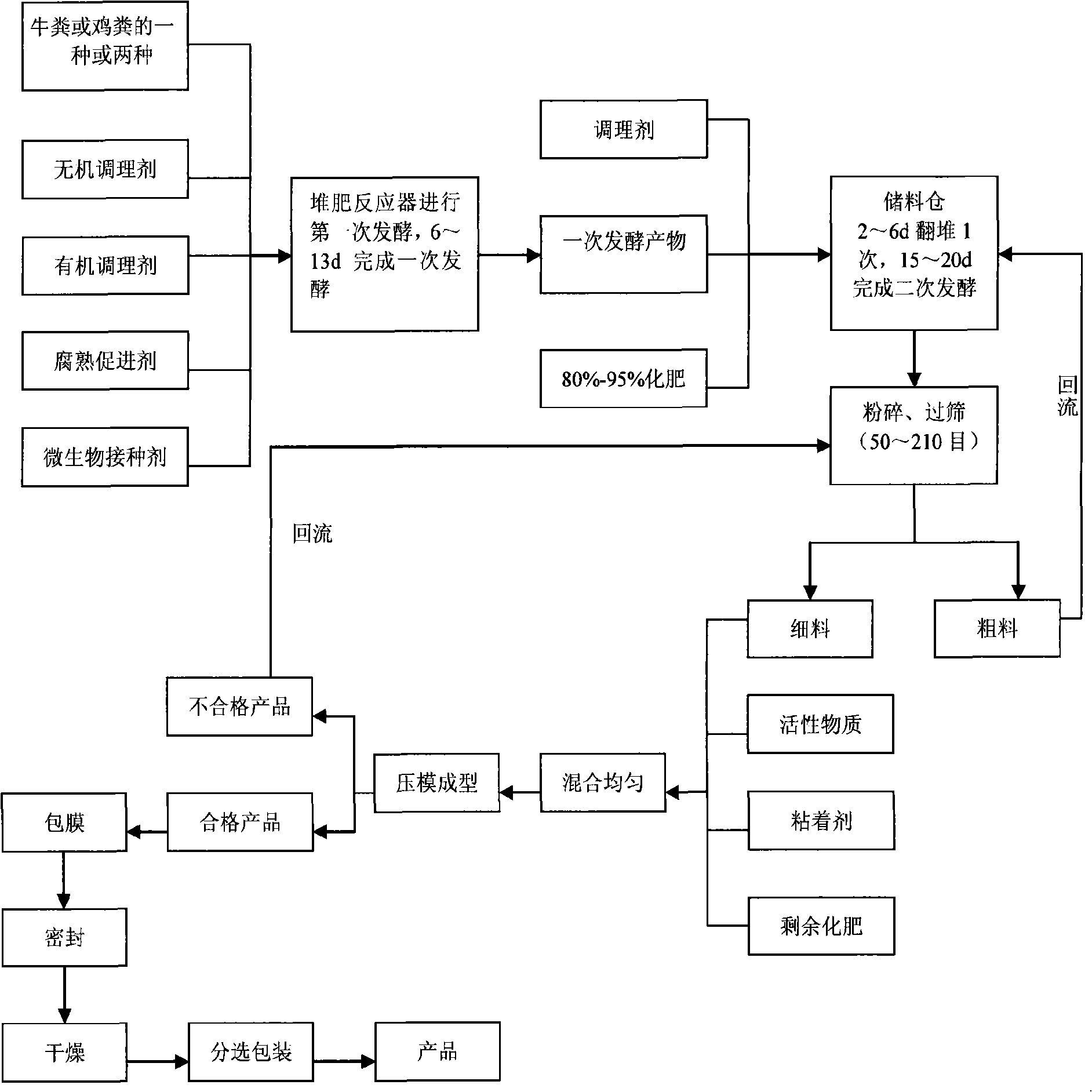

Method used

Image

Examples

Embodiment 1

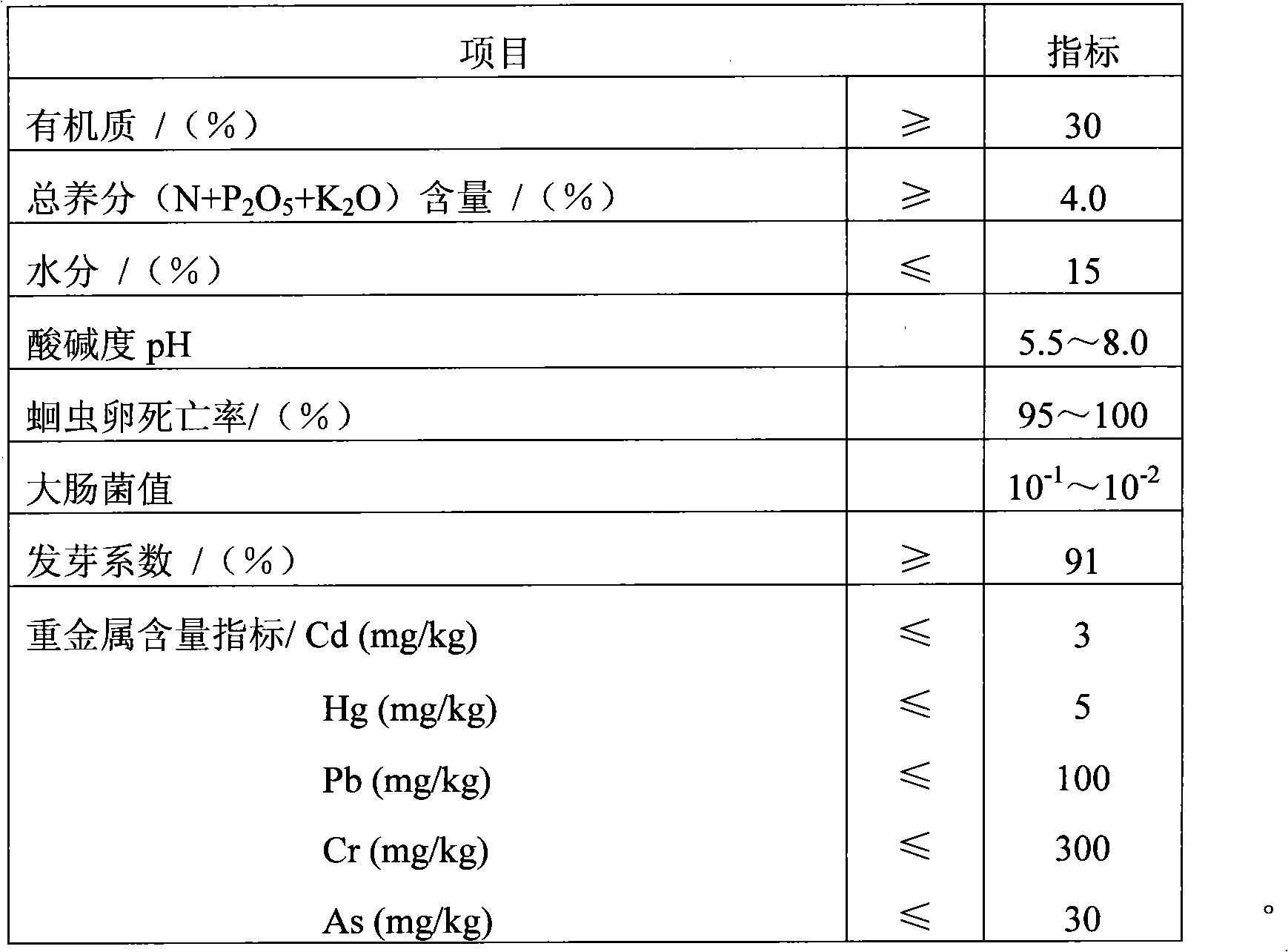

[0046] 1. Prepare primary fermentation products according to the following method: uniformly mix 300kg of cow dung, 300kg of chicken manure, 200kg of fly ash, 90kg of soy sauce residue, 60kg of crop straw, and 50kg of yeast waste liquid. According to the composting parameters, pH is 6, carbon and nitrogen The mass ratio of the compost mixture is 20:1, so that the moisture content of the final compost mixture reaches 65%; Enter the enzyme bacteria quick-rot agent; the compost temperature rises to 60 ° C, and after 48 hours, it starts to turn the compost. By stirring and forced ventilation, the oxygen content in the compost body is kept at 5%, and the temperature in the composting reactor is controlled at 60 °C. ℃, after 10 days to obtain a fermentation product;

[0047]2. Fully mix 45kg of primary fermentation products, 18.25kg of potassium dihydrogen phosphate, 15kg of diammonium phosphate and 10kg of copper sulfate, and transfer them to a storage bin designed with a heated ka...

Embodiment 2

[0051] 1. Prepare a primary fermentation product as follows: 700kg of cow dung is uniformly mixed with 70kg of phosphate rock powder, 80kg of alkali-making waste residue, 120kg of litter, 10kg of molasses, and 20kg of yeast waste liquid. According to the composting parameters, pH is 5.5, carbon The mass ratio of nitrogen is 25: 1, so that the moisture content of the final compost mixture reaches 40%; the final compost mixture is packed into the compost reactor, and the weight ratio of the enzyme bacteria quick-rot agent and the compost mixture is 1: 500. Insert the enzyme bacteria quick-rot agent; when the compost temperature rises to 65°C, keep it for 48 hours and then start turning the compost. By stirring and forced ventilation, the oxygen content in the compost body is kept at 15%, and the temperature in the composting reactor is controlled. At 55°C, a fermentation product was obtained after 6 days;

[0052] 2. Fully mix 50kg of primary fermentation products, 1.6kg of urea...

Embodiment 3

[0056] 1. Prepare a primary fermentation product as follows: combine 560kg of chicken manure with 50kg of phosphate rock powder, 80kg of alkali-making waste residue, 20kg of mineral potassium, 180kg of soy sauce residue, 20kg of litter, 50kg of humic acid, 20kg of distiller’s grains and 20kg of monosodium glutamate waste Mix the solution evenly, according to the compost parameters pH is 8.5, the mass ratio of carbon and nitrogen is 30:1, so that the moisture content of the final compost mixture reaches 60%; Add VT-1000 inoculum in a weight ratio of 1:10 to the compost mixture; when the compost temperature rises above 70°C and keeps for 48 hours, turn the compost. When the temperature exceeds 70°C, turn the compost immediately and stir and forced ventilation to keep the oxygen content in the heap at 8%, control the temperature in the composting reactor at 65°C, and obtain a fermentation product after 8 days;

[0057] 2. Fully mix 60kg of primary fermentation products, 4kg of di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com