House refuse treatment method

A treatment method and technology for domestic waste, applied in the biological organic part treatment, separation method, water/sewage treatment and other directions, can solve the problems of many impurities, damage to crops, large area, etc., and achieve good economic benefits and good market prospects. , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific embodiment is described below in conjunction with accompanying drawing:

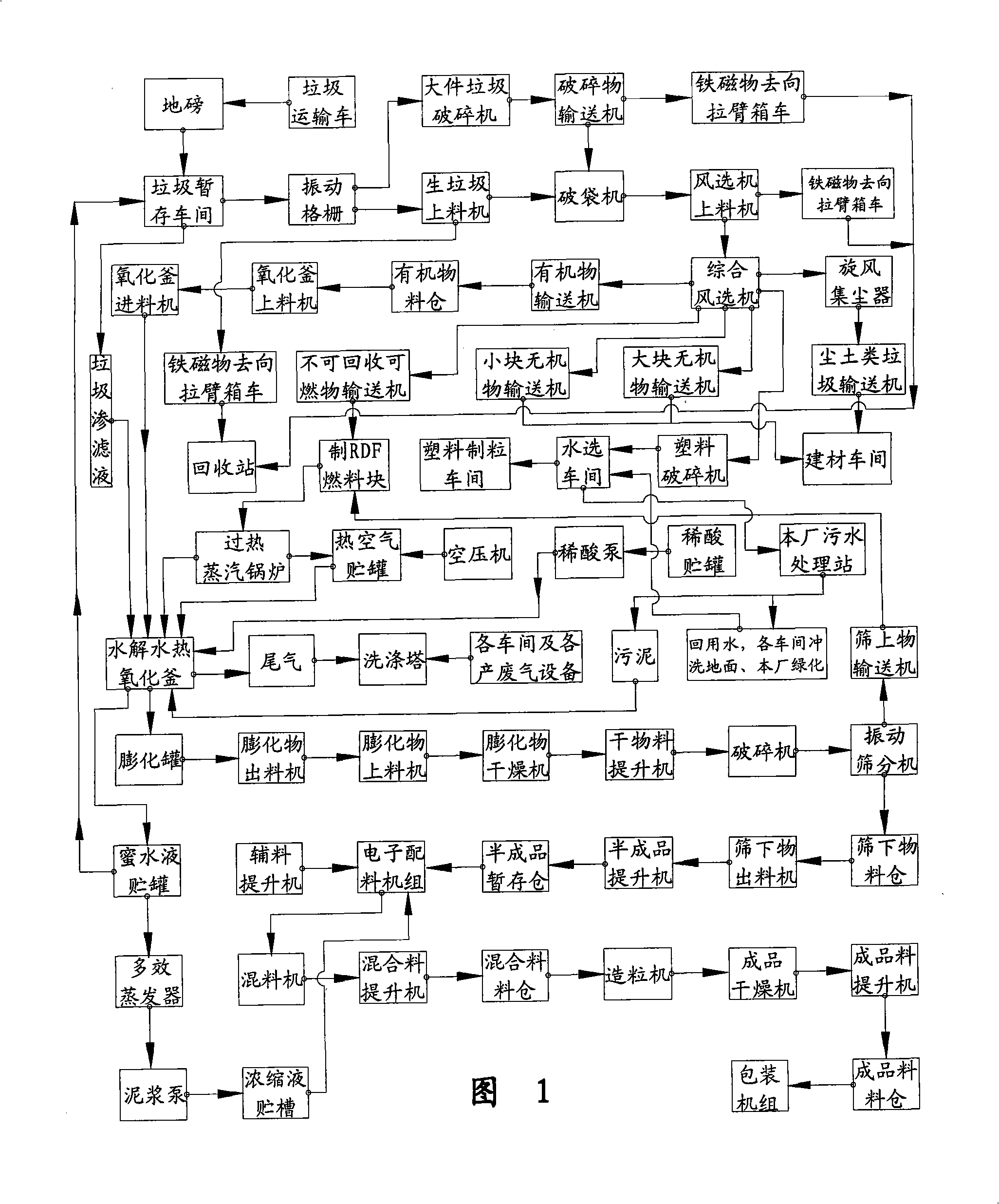

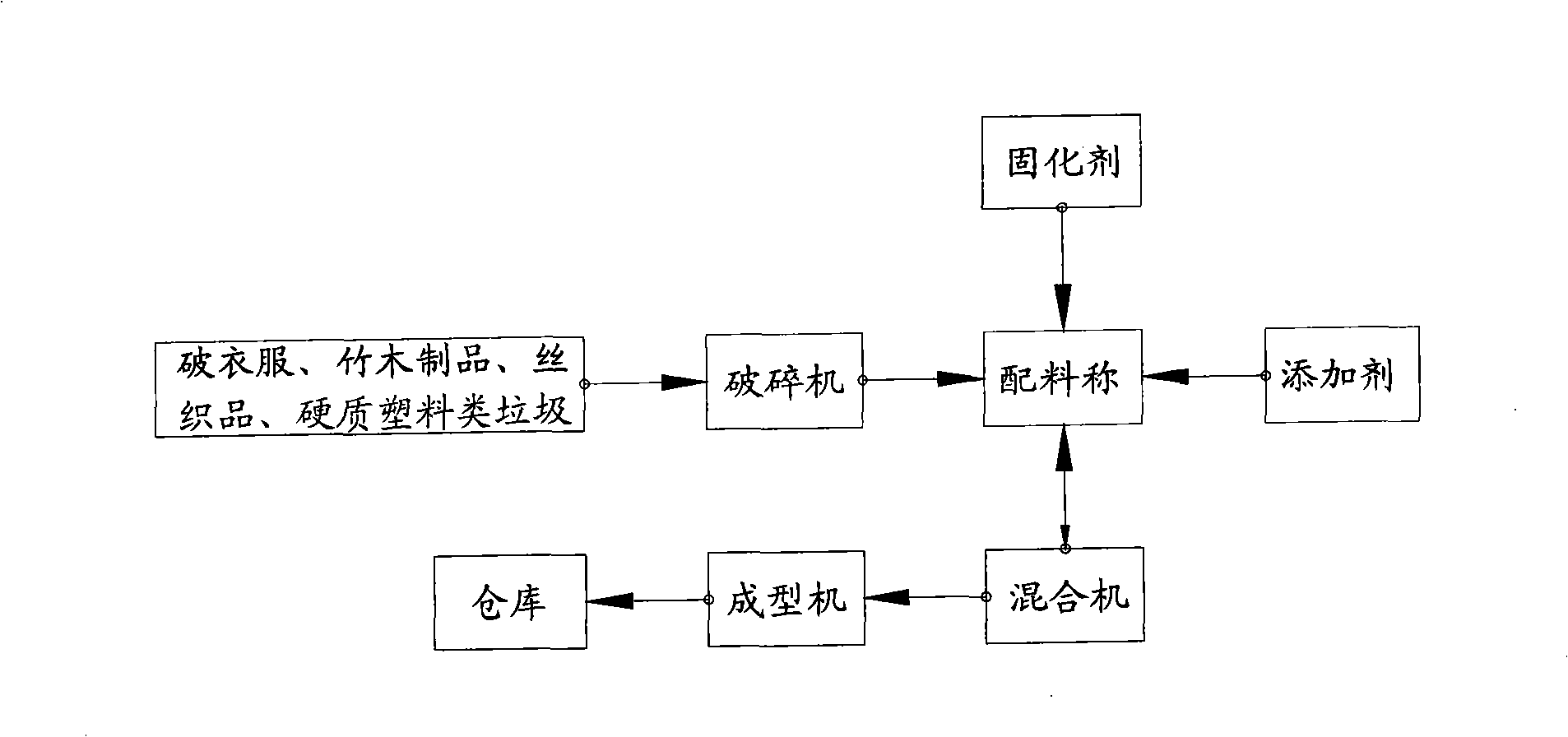

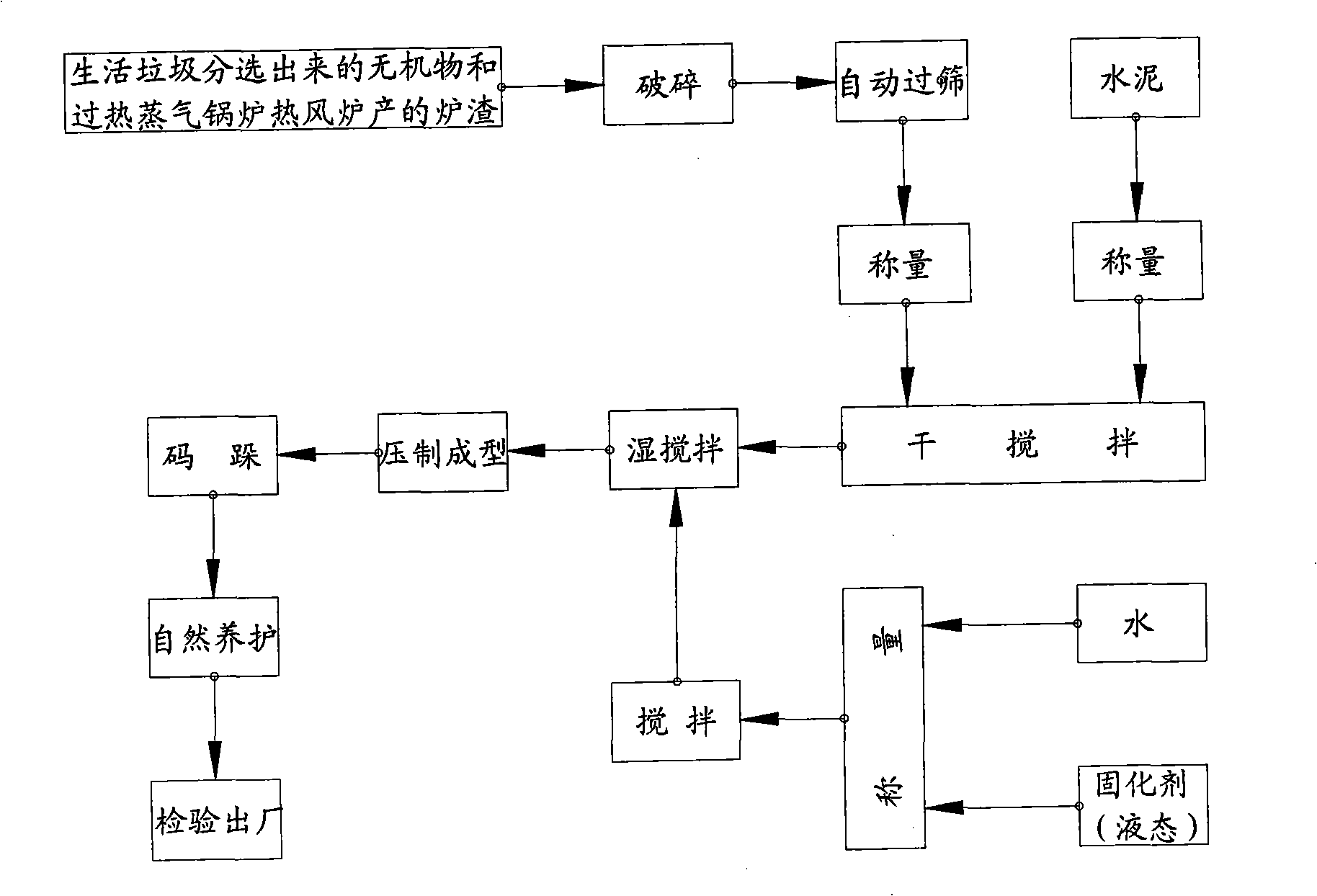

[0047] Figure 1 to Figure 5 Shown, the concrete processing steps of the processing method of house refuse of the present invention are as follows:

[0048] 1. Fully enclosed, mechanized, no manual sorting system (wind selection plus water selection):

[0049]The domestic garbage is transported in by the garbage truck. After the weighbridge is overweight, the garbage truck enters the garbage truck rotary workshop, and the garbage is unloaded on the vibrating grid. After rough selection by the vibrating grid, the bulky garbage (particle ) and go to the large-size garbage crusher. After the crushed garbage is magnetically separated by the permanent magnet roller conveyor, the ferromagnetic objects go to the recycling warehouse, and the rest of the broken objects go to the garbage bag crusher. After being crushed again, they go to the next process to participate Wind separation; the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com