Antistatic paint for steel structure surface and preparation method thereof

An anti-static coating and steel structure technology, applied in conductive coatings, coatings, etc., can solve problems such as coating peeling and cracking, achieve high adhesion, improve flexibility, increase wettability and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

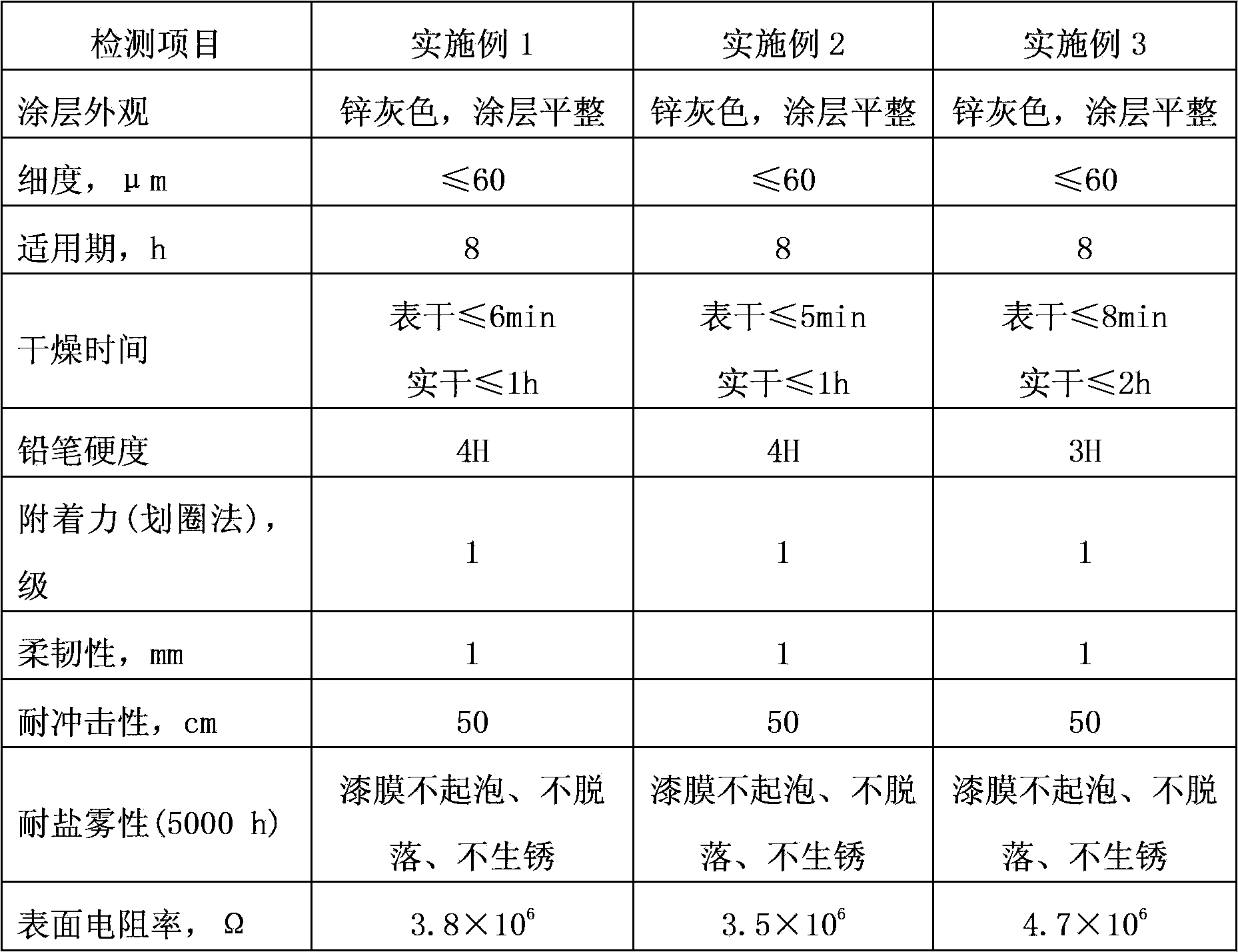

Examples

Embodiment 1

[0027] In this embodiment, the antistatic material on the surface of the steel structure is formed by mixing zinc-aluminum alloy powder slurry and tetraethyl orthosilicate slurry at a mass ratio of 4:1; in terms of mass percentage, the zinc-aluminum alloy powder slurry includes 75 parts of zinc aluminum alloy powder, 3 parts of absolute ethanol, 2 parts of n-butanol, 1 part of furfural furfuryl alcohol resin as a modifier, 0.5 parts of coupling agent bis(1,2-triethoxysilyl)ethane, 0.5 parts of organic bentonite, 0.5 parts of BYK's DISPERBYK-190, 0.5 parts of carbon nanotube dispersion, 9.5 parts of conductive mica powder, 2 parts of ferrophosphorus powder, 2 parts of talcum powder, 2 parts of zinc oxide, 0.5 parts of silicic acid aluminum fiber, 0.5 parts of aluminum borate whiskers, and 0.5 parts of polyvinyl butyral; in terms of mass percentage, the tetraethyl orthosilicate slurry is composed of 40 parts of tetraethyl orthosilicate, 8 parts of catalyst, 38 parts of Water eth...

Embodiment 2

[0033] In this embodiment, the antistatic material on the surface of the steel structure is formed by mixing zinc-aluminum alloy powder slurry and tetraethyl orthosilicate slurry in a mass ratio of 3:1;

[0034] In terms of mass percentage, the zinc-aluminum alloy powder slurry includes 65 parts of zinc-aluminum alloy powder, 5 parts of absolute ethanol, 3 parts of n-butanol, 2 parts of furfural furfuryl alcohol resin as a modifier, 2 parts of a coupling agent vinyl Triethoxysilane, 1 part of polyamide wax, 1 part of BYK-P 104S, 1.5 parts of carbon nanotube dispersion, 9.5 parts of conductive mica powder, 4 parts of ferrophosphorus powder, 2 parts of talc powder, 2 parts Zinc oxide, 1 part of red iron oxide, 0.5 part of mullite whiskers, and 0.5 part of polyvinyl butyral; in terms of mass percentage, the tetraethyl orthosilicate slurry is composed of 45 parts of orthoethyl silicate , 6 parts of catalyzer, 35 parts of absolute ethanol, 14 parts of n-butanols; the catalyzer is d...

Embodiment 3

[0040] In this embodiment, the antistatic material on the surface of the steel structure is formed by mixing zinc-aluminum alloy powder slurry and tetraethyl orthosilicate slurry at a mass ratio of 5:1; in terms of mass percentage, the zinc-aluminum alloy powder slurry includes 60 parts of zinc aluminum alloy powder, 7 parts of absolute ethanol, 4 parts of n-butanol, 3 parts of furfural furfuryl alcohol resin as a modifier, 2 parts of coupling agent isopropyl tri(dioctyl phosphate) titanate, 2 parts Organic bentonite, 2 parts of DISPERBYK-190, 1 part of carbon nanotube dispersion, 10 parts of conductive mica powder, 2 parts of ferrophosphorus powder, 2 parts of talcum powder, 2 parts of zinc oxide, 1 part of aluminum silicate fiber , 1 part of aluminum borate whiskers and 1 part of polyvinyl butyral; according to mass percentage, the tetraethyl orthosilicate slurry is composed of 50 parts of tetraethyl orthosilicate, 8 parts of catalyst, 30 parts of absolute ethanol , 12 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com