Novel electrostatic dust removing structure

A new type of electrostatic precipitator technology, applied in the field of dry electrostatic precipitator structure, can solve the problems of secondary pollution, poor wastewater, large wastewater, etc., to improve the dust removal efficiency, improve the coagulation and agglomeration effect, and effectively capture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

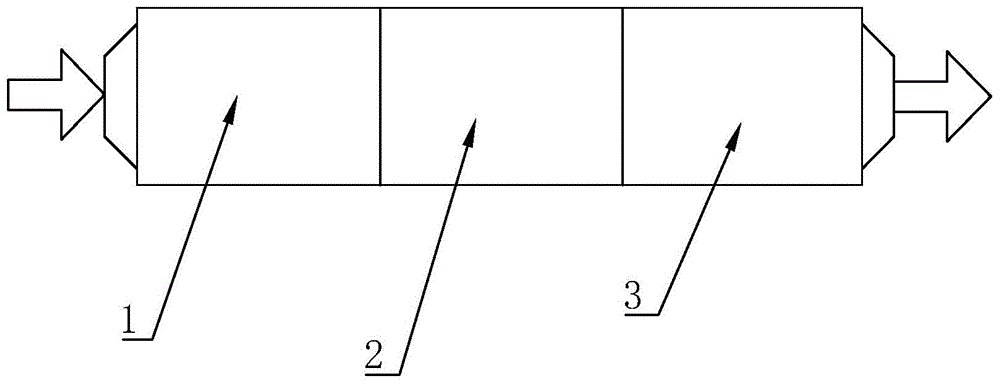

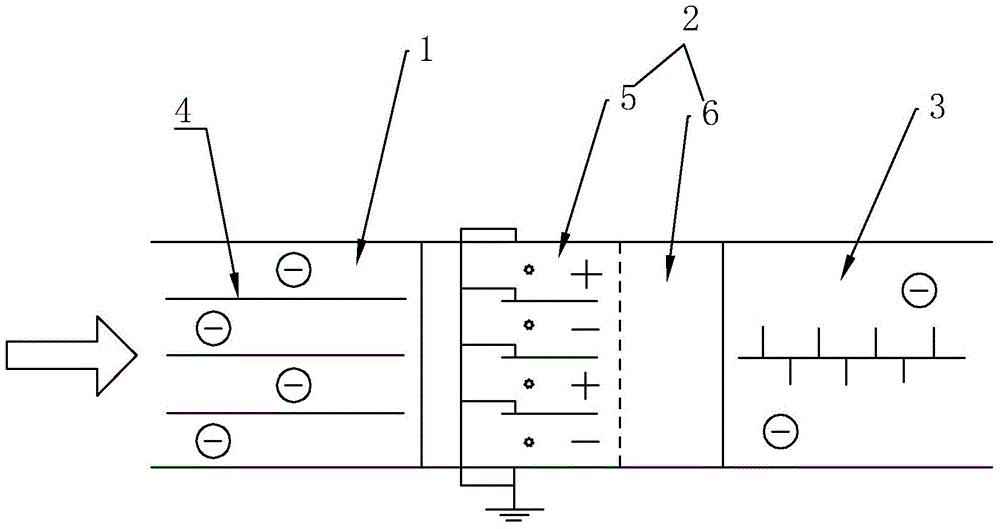

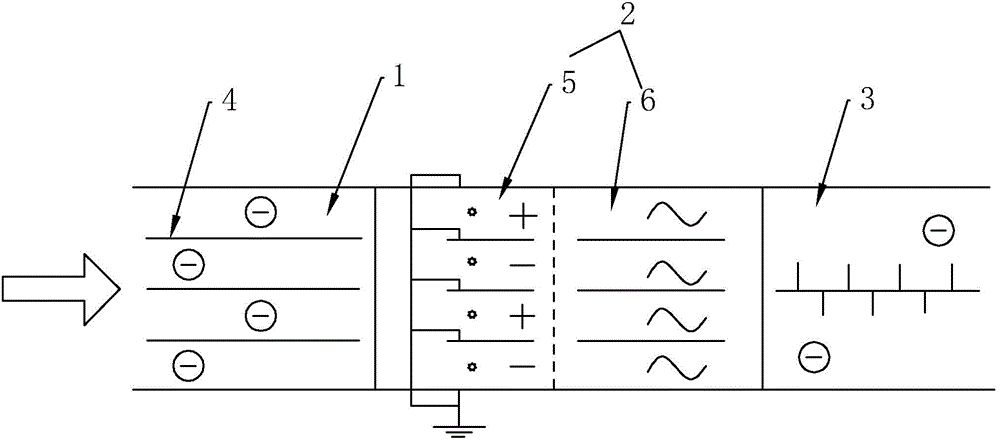

[0030] refer to figure 1 As shown, a new type of electrostatic precipitator structure in this embodiment includes a pre-dust removal area 1, an electrocoagulation merger area 2, and a fine particle collection area 3 that are connected to each other in sequence. The pre-dust removal area 1 is far away from the electrocoagulation merger area 2. One end is connected to the flue gas discharge outlet, which is used to filter the dust particles with medium and large particle sizes. The dust particles after passing through the pre-dust removal area 1 enter the electrocoagulation area 2, and the electrocoagulation area 2 coagulates the small particle size dust particles into Larger dust particles, after the larger dust particles enter the fine particle trapping area 3, the larger dust particles are captured by the fine particle trapping area 3.

[0031] The dust-laden flue gas is discharged from the outlet and enters the pre-dust removal area 1. Through the dust removal of the pre-dus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com