Precision forming method and device of flanged flat gears

A precision forming and gear technology, applied in forging/pressing/hammer devices, wheels, transportation and packaging, etc., can solve the problems of insufficient filling of gear teeth and increased extrusion force, so as to control the cost of a single piece and facilitate the production of a single piece Cost, the effect of guaranteeing the life of the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

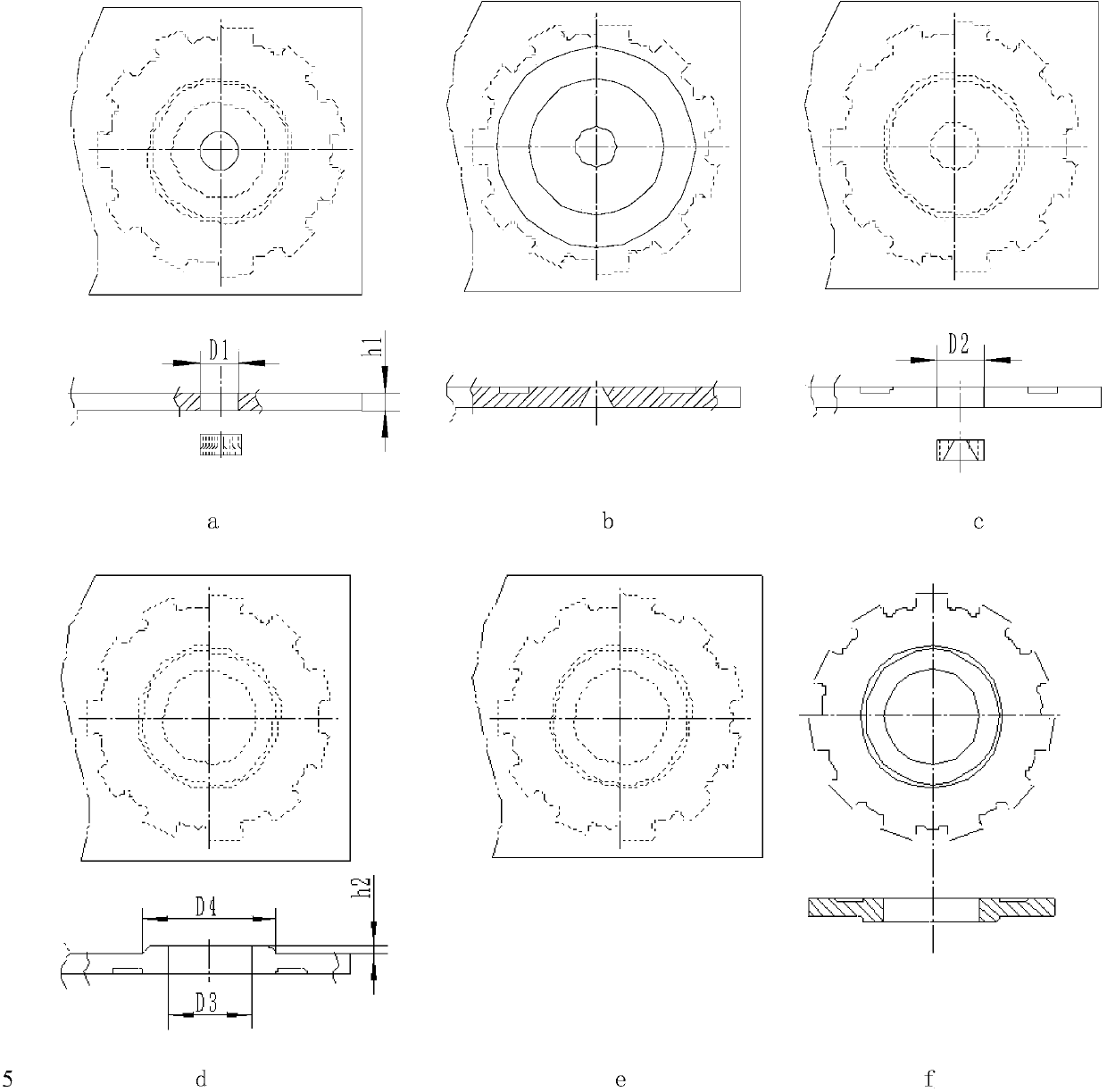

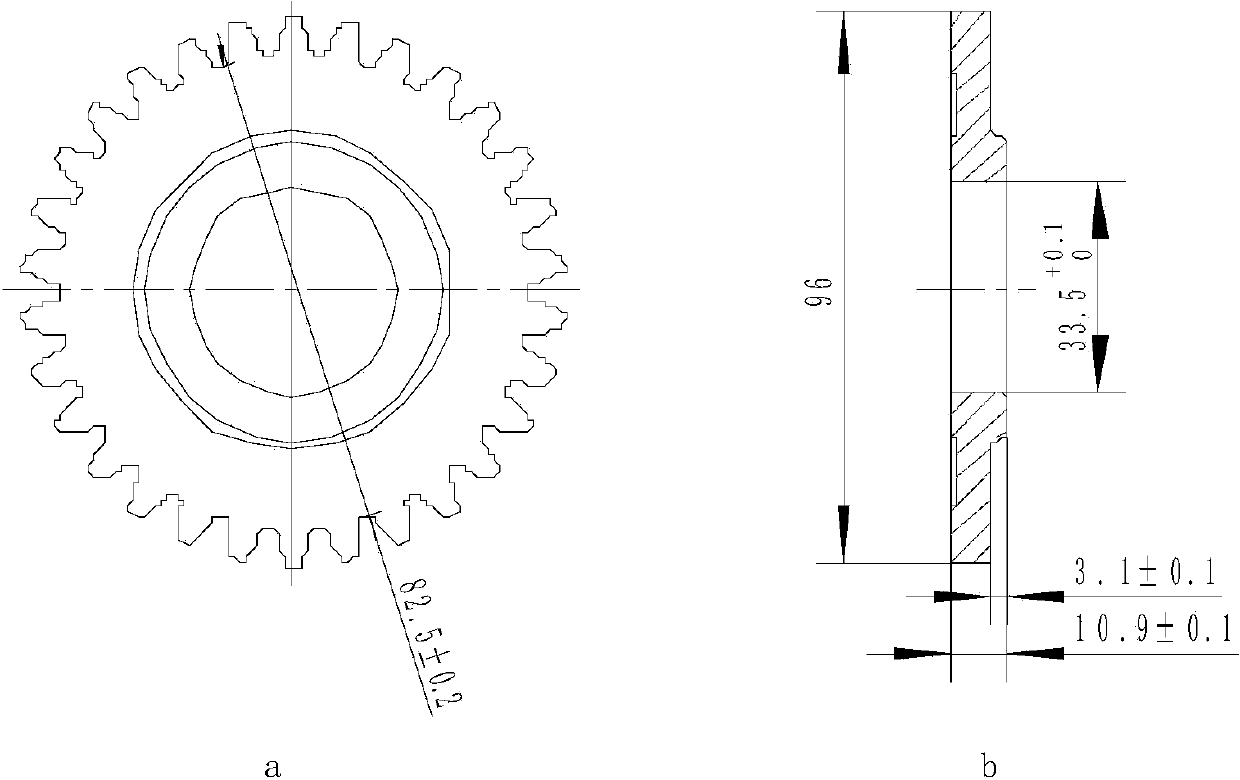

[0029] Such as figure 1 As shown, this embodiment includes the following steps:

[0030] The first step, blank preparation, adopts strip material, such as image 3 As shown, the thickness of the blank is taken as the thickness of the tooth portion of the involute tooth, and the width of the blank is 1.2 times the diameter of the addendum circle; the strips used must be spheroidized annealed, and the spheroidization rate is greater than or equal to 85%.

[0031] The second step is to punch the center hole, which is a process auxiliary hole and plays the role of a diverter hole in the next forming process. The diameter of the central hole is reduced by 1.0 mm on one side compared with the pre-punched hole.

[0032] The third step is to extrude the annular groove to form the upper flange. The annular groove is obtained by extrusion deformation. During the extrusion process, the excess metal flows radially inward into the center hole. After the annular groove is extruded, the up...

Embodiment 2

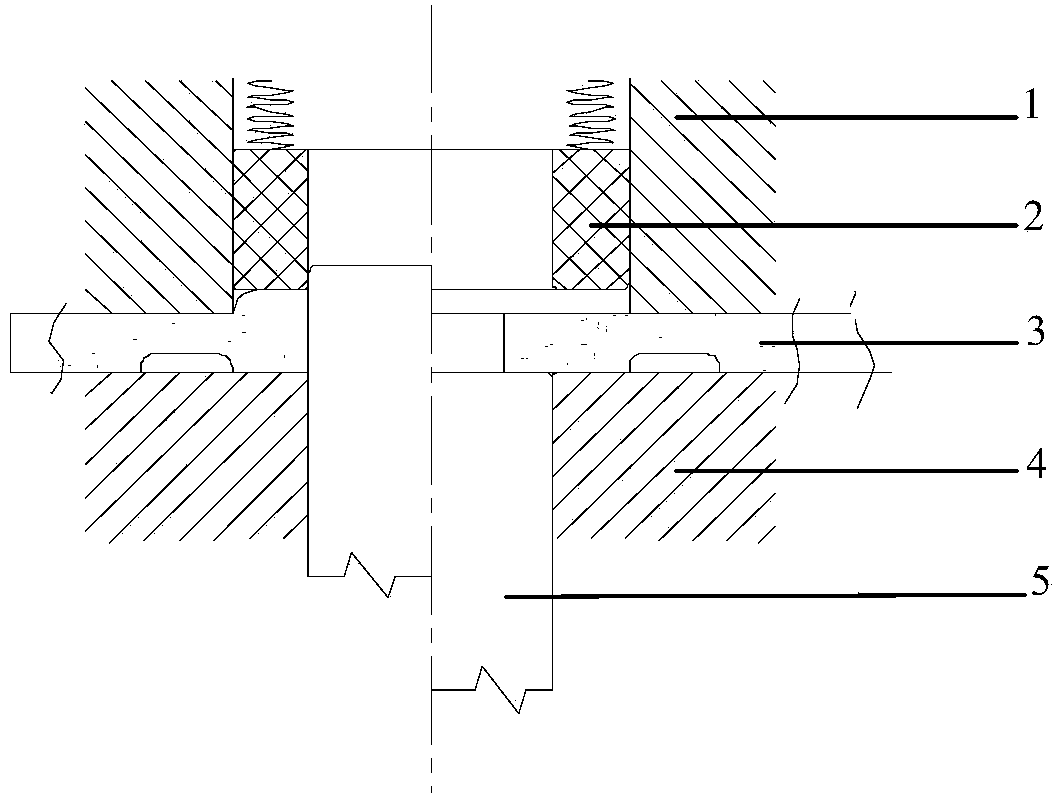

[0038] Such as figure 2 Shown, be applied to the device of embodiment 1, this device is the compound mold that is used for flanging and upsetting and comprises: patrix, counterdie, upper die and lower punch, wherein: patrix moves downward earlier, and The lower mold presses the billet together and applies a pressure of 15 MPa, the lower punch moves upward to form the flanging, and then the floating-controlled upper die moves downward to upset to the target height of the lower flange of the gear to be manufactured.

[0039] The floating control refers to using an independent hydraulic pump to control the upward or downward movement of the upper die.

[0040] The upper die is a simple ring structure, which is convenient for its processing and manufacturing, and is driven by a floating control unit to work.

Embodiment 3

[0042] This embodiment includes the following steps:

[0043] The first step, blank preparation, adopts strip material, such as Figure 4 As shown, the thickness of the blank is taken as the thickness of the tooth part of the rectangular gear, and the width of the blank is 1.1 times the diameter of the addendum circle; the strips used must be spheroidized annealed, and the spheroidization rate is greater than or equal to 85%.

[0044] The second step is to punch the center hole, which is a process auxiliary hole and plays the role of a diverter hole in the next forming process. The diameter of the central hole is reduced by 1.5 mm on one side compared with the pre-punched hole.

[0045] The third step is to extrude the annular groove to form the upper flange. The annular groove is obtained by extrusion deformation. During the extrusion process, the excess metal flows radially inward into the center hole. After the annular groove is extruded, the upper flange of the gear part ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com