Adhesive filling and grinding processing method for stator-rotor iron core component of motor

A core and grinding technology, used in the manufacture of stator/rotor bodies, etc., can solve the problems of cracking length, out-of-tolerance, scrap, etc., and achieve the effect of solving cracking, avoiding intermittent cutting, and good cooling conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0028] The glue filling grinding process of the motor stator and rotor core assembly, the processing steps are as follows:

[0029] (1) The laminations are glued, and the armature punching sheets are bonded and laminated to form an iron core assembly;

[0030] (2) Fitter: grind the two ends of the iron core assembly to ensure the parallelism of the end faces;

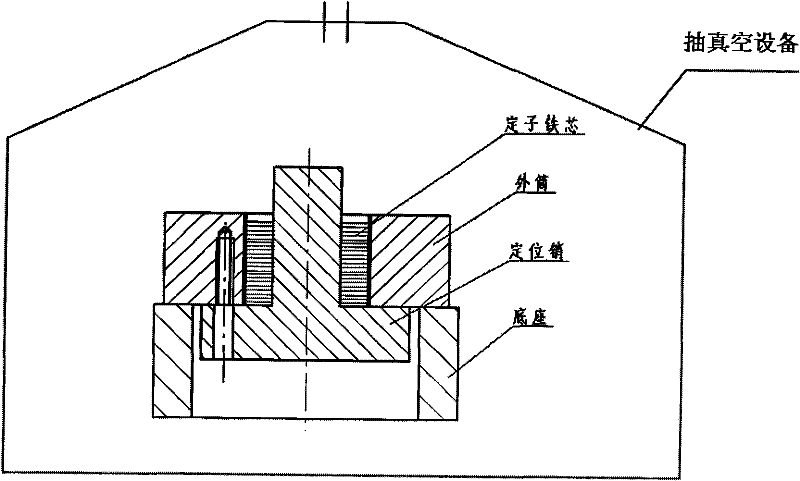

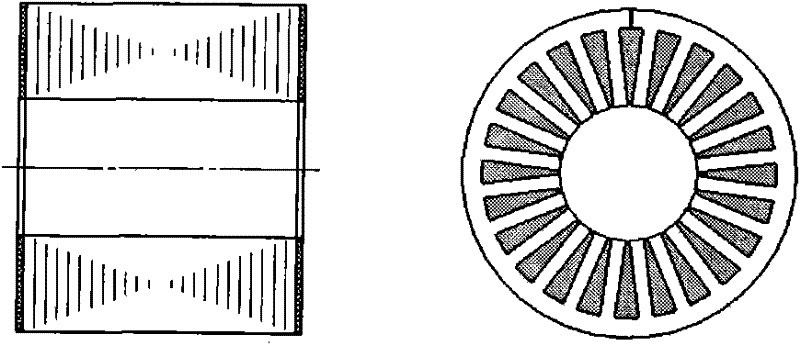

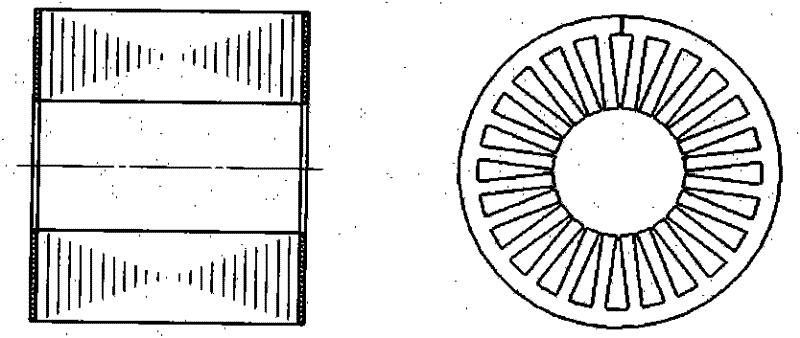

[0031] (3) Glue filling: Fill the colloid in the iron core groove by vacuum, see figure 1 and figure 2 , this step is the key to the whole process:

[0032] a) Mold loading: the mold is composed of an outer cylinder, positioning pins, base, and connecting screws, and the iron core assembly is placed on the positioning pins;

[0033] b) Preheating the mold: put the mold with iron core in an oven at 120°C to 130°C to preheat for 0.5 to 2 hours;

[0034] c) Potting: Put the potting compound in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com