A method of manufacturing a fishing rod

A manufacturing method and fishing rod technology, applied in fishing rods, fishing, applications, etc., can solve problems such as low sensitivity, poor conductivity of fishing rods, and easy breakage of the rod body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A method for manufacturing a fishing rod, the steps are as follows:

[0019] 1. A layer of epoxy mesh cloth is superimposed on the carbon fiber cloth, which is the same as the prior art and will not be described again.

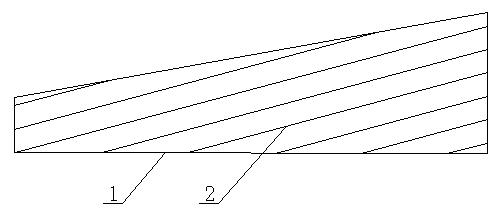

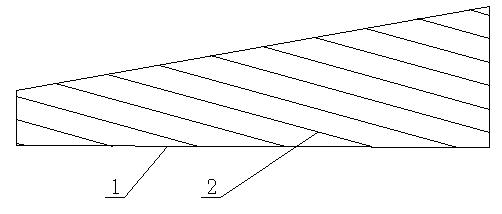

[0020] 2. Cut out at least two pieces of main cloth according to the size required by the design. The reference side 1 of the main cloth and the carbon fiber pattern 2 form an angle of 5°-25°, generally 15°. From figure 1 , figure 2 It can be seen from the figure that the reference edge 1 of the main fabric is 15° to the carbon fiber pattern 2, and there are two forms of the 15° included angle. One is that the reference edge 1 turns 15° clockwise and is parallel to the carbon fiber pattern 2, and the other is the reference edge 1. Side 1 is turned counterclockwise by 15° and parallel to carbon fiber texture 2.

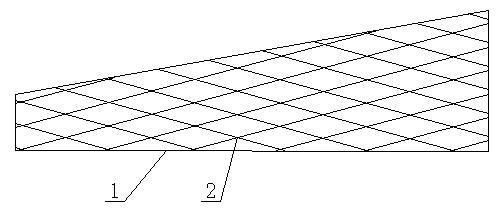

[0021] 3. Superimpose and paste the main fabrics together, in which the carbon fiber lines of two adjacent main fabrics are crossed, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com