Manufacturing technology of hollow outer gear of electric forklift driving flange

A technology for transmission flanges and electric forklifts, which is applied in the processing technology of flange ring gears. It can solve the problems of high manufacturing accuracy and tooth surface strength, low utilization rate of metal materials, and reduced mechanical strength, so as to achieve stable product quality. , Saving raw materials and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further specifically described below through embodiments and in conjunction with the accompanying drawings.

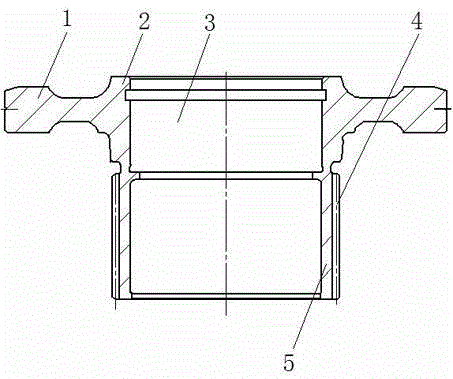

[0017] An electric forklift transmission flange hollow external gear, one end is a flange end 1, the other end is a hollow cylinder 5 with external teeth 4, and the upper part of the outer wall flange end 1 of the hollow cylinder 5 is provided with a circular small boss 2 , there is a transition section between the outer tooth 4 and the flange end 1 on the outer wall of the hollow cylinder 5, the diameter of the central hole 3 of the hollow cylinder 5 is Φ70.2mm, the parameters of the outer tooth 4: root diameter Φ87.8mm, tooth The top diameter is Φ94.36mm, the index circle diameter is Φ92.075mm, the number of teeth is 29, and the tooth taper angle is 30°.

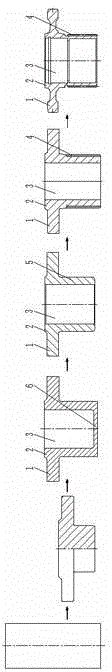

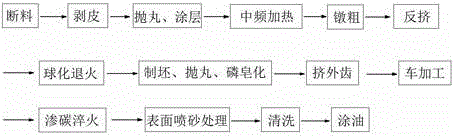

[0018] The manufacturing process of the hollow external gear of the transmission flange of the electric forklift includes the following steps: ① Warm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com