Gear processing technology

A processing technology and gear technology, applied in the field of gear processing technology, can solve the problems of poor ability to overcome axial force, many factors of processing quality, slow workpiece clamping speed, etc., and achieve enhanced ability of reciprocating axial force , The cost saving of the full tooth pitch circular fixture and the effect of increasing the clamping speed of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

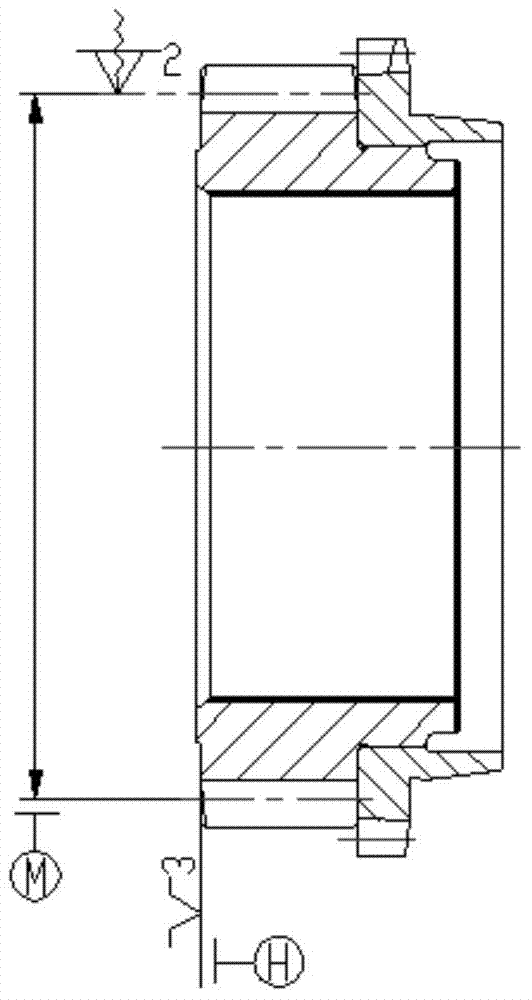

[0044] It is not difficult to find out by analyzing the prior art that the generation of these problems in the prior art is related to the full pitch circle clamp. Therefore, the present invention improves the positioning and clamping methods of process 10 grinding inner hole and end face process in the prior art, cancels the full pitch circle fixture, and adopts the method of directly clamping the tooth top reference circle with the film clamp jaw to replace the full pitch circle fixture. The specific embodiment process is as follows:

[0045] The invention provides a gear processing technology, which is carried out according to the following procedures,

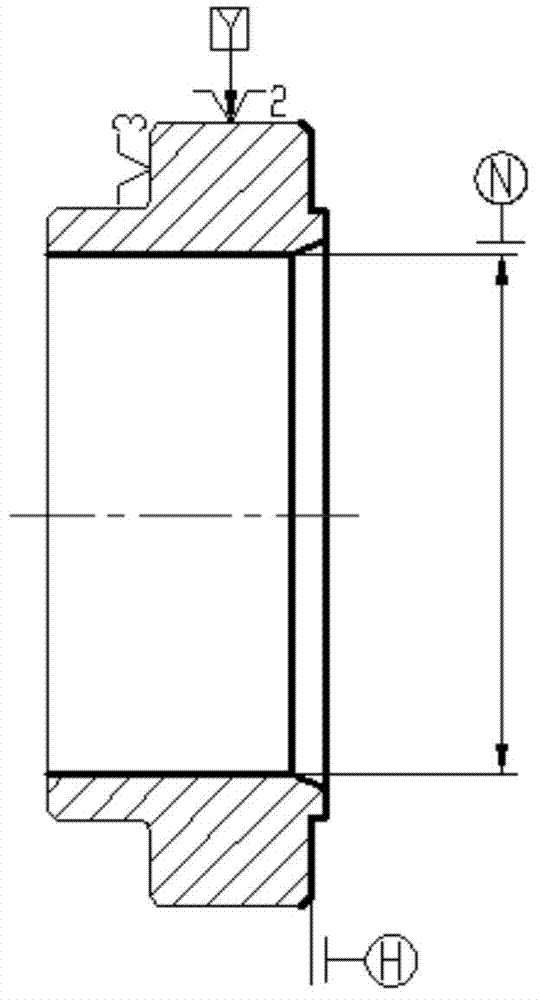

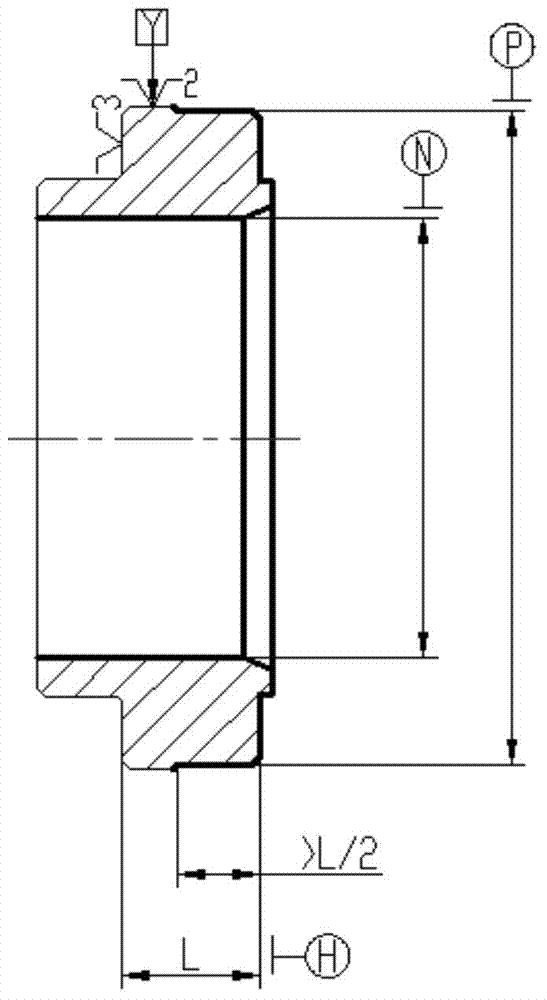

[0046] Process 1, car one, specifically the car out of the reference hole, reference end face and reference circle, in this embodiment, in process 1, car one, such as figure 2 As shown, it is a schematic diagram of process 1 turning and process provided by the present invention. In one clamping, when the reference hole N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com