Method for forging 17CrNiMo6 steel wind power generation gear

A gear forging and gear technology, which is applied in the forging field of 17CrNiMo6 steel wind power generation gears, can solve the problems of unreasonable forging process parameters, the decline of comprehensive mechanical properties of wind power generation gears, and the reduction of service life of wind power generation gears, so as to eliminate internal organization The effect of stress, improving comprehensive mechanical properties, and inhibiting the formation of crystal nuclei

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

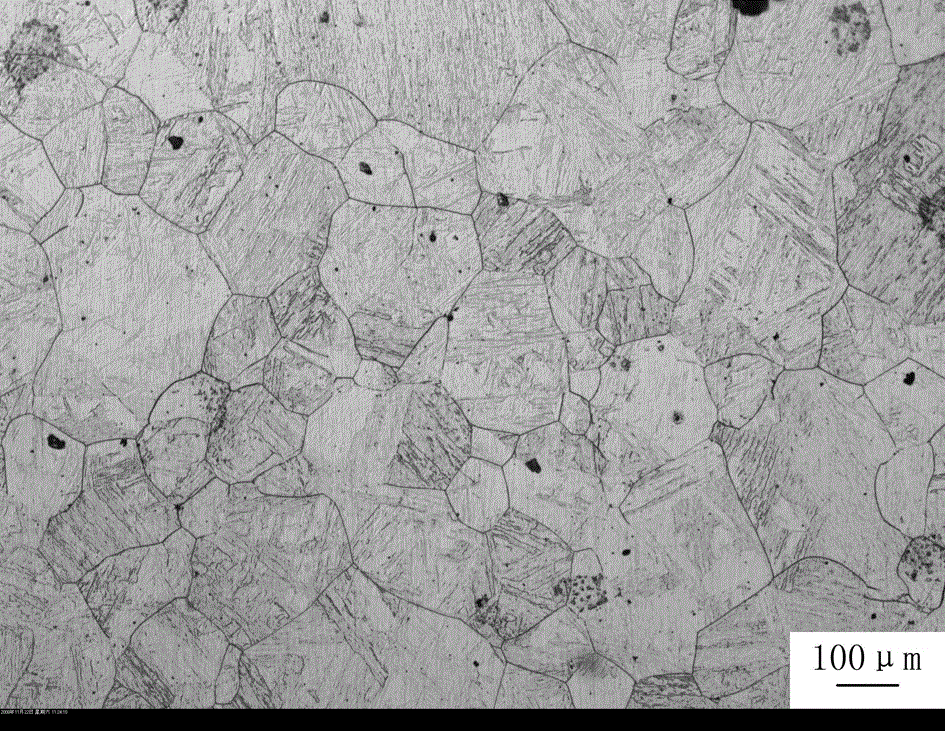

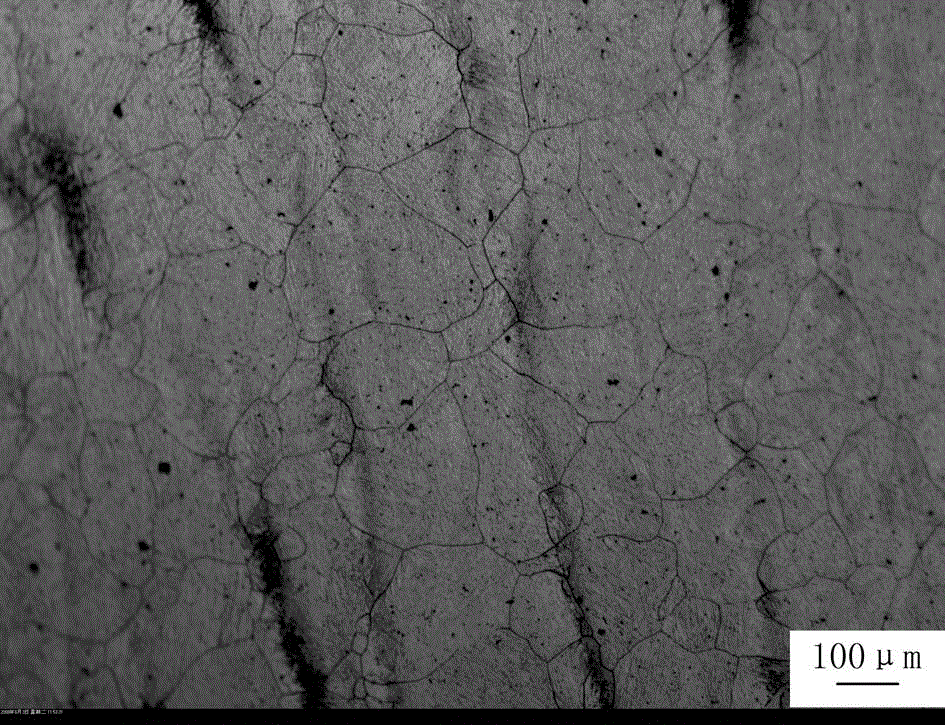

[0023] In this embodiment, the forging is a 2m×Φ1m cylindrical 17CrNiMo6 steel ingot. The 17CrNiMo6 steel ingot is provided by Taiyuan Heavy Machinery Co., Ltd. The steel is low-carbon high-alloy stainless steel, which has good mechanical properties and strong corrosion resistance. It is an excellent raw material for preparing wind power gears, but unlike ordinary low-carbon high-alloy stainless steel forging process, it is easy to produce feathery or reticular bainite inside the structure during forging, which reduces the comprehensive mechanical properties of wind power gears.

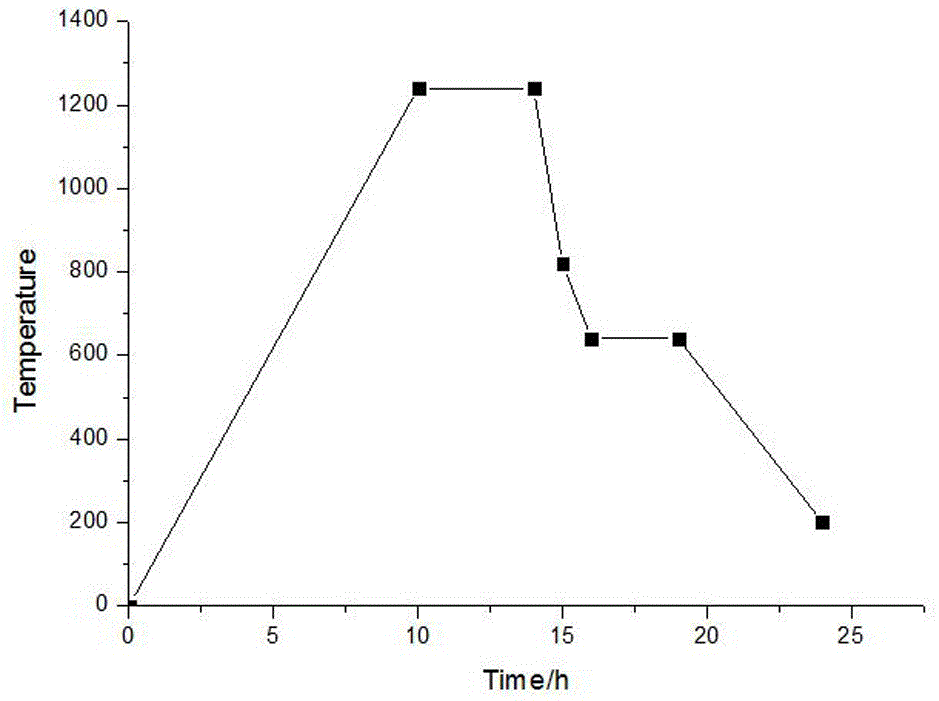

[0024] Such as Figure 1~5 Shown, a kind of 17CrNiMo6 steel wind power generation gear forging method is characterized in that adopting following steps to carry out successively:

[0025] (1) Pre-forging treatment: put the forging blank in the heating furnace, heat the furnace to 1230°C and put the blank into the heating furnace, keep it warm for 4 hours according to the size of the blank, and obtain...

Embodiment 2

[0030] A kind of 17CrNiMo6 steel forging method for wind power generation gear is characterized in that adopting following steps to carry out successively:

[0031] (1) Pre-forging treatment: place the forging blank in a heating furnace, heat the furnace to 1240°C and put the blank into the heating furnace, and keep it warm for 6.5 hours according to the size of the blank;

[0032] (2), forging molding:

[0033] Put the heated blank into a forging mold consisting of a die, a punch, a sleeve and an ejector mechanism. The initial forging temperature is 1240°C, the final forging temperature is 830°C, and the punch and die are pressed. The forging ratio of the single pass of the first fire is 1.73, and the forging ratio of the last pass is 1.87, with 0.5s -1 The deformation rate makes the blank form together along the inner wall of the mold; after holding the pressure for 7s, the punch and die are unloaded and returned, and after the blank is demoulded, the forged gear is ejected...

Embodiment 3

[0037] A kind of 17CrNiMo6 steel forging method for wind power generation gear is characterized in that adopting following steps to carry out successively:

[0038] (1) Pre-forging treatment: place the forging blank in a heating furnace, heat the furnace to 1250°C and put the blank into the heating furnace, and keep it warm for 10 hours according to the size of the blank;

[0039] (2), forging molding:

[0040] Put the heated blank into a forging mold consisting of a die, a punch, a sleeve and an ejector mechanism. The initial forging temperature is 1250°C, the final forging temperature is 840°C, and the punch and die are pressed. The forging ratio is 2 for the single pass of the fire time, and the forging ratio for the last pass is 2, with 1s -1 The deformation rate makes the blank form together along the inner wall of the sleeve mold; after holding the pressure for 10s, the punch and die are unloaded and returned, and after the blank is demoulded, the forged gear is ejected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com