Evolent straight-gear conic-gear direct-finishing method

A technology of bevel gears and involutes, applied in the field of gear manufacturing, can solve the problems of no parameterization, inaccuracy, and complicated modification methods, and achieve the effect of solving meshing contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

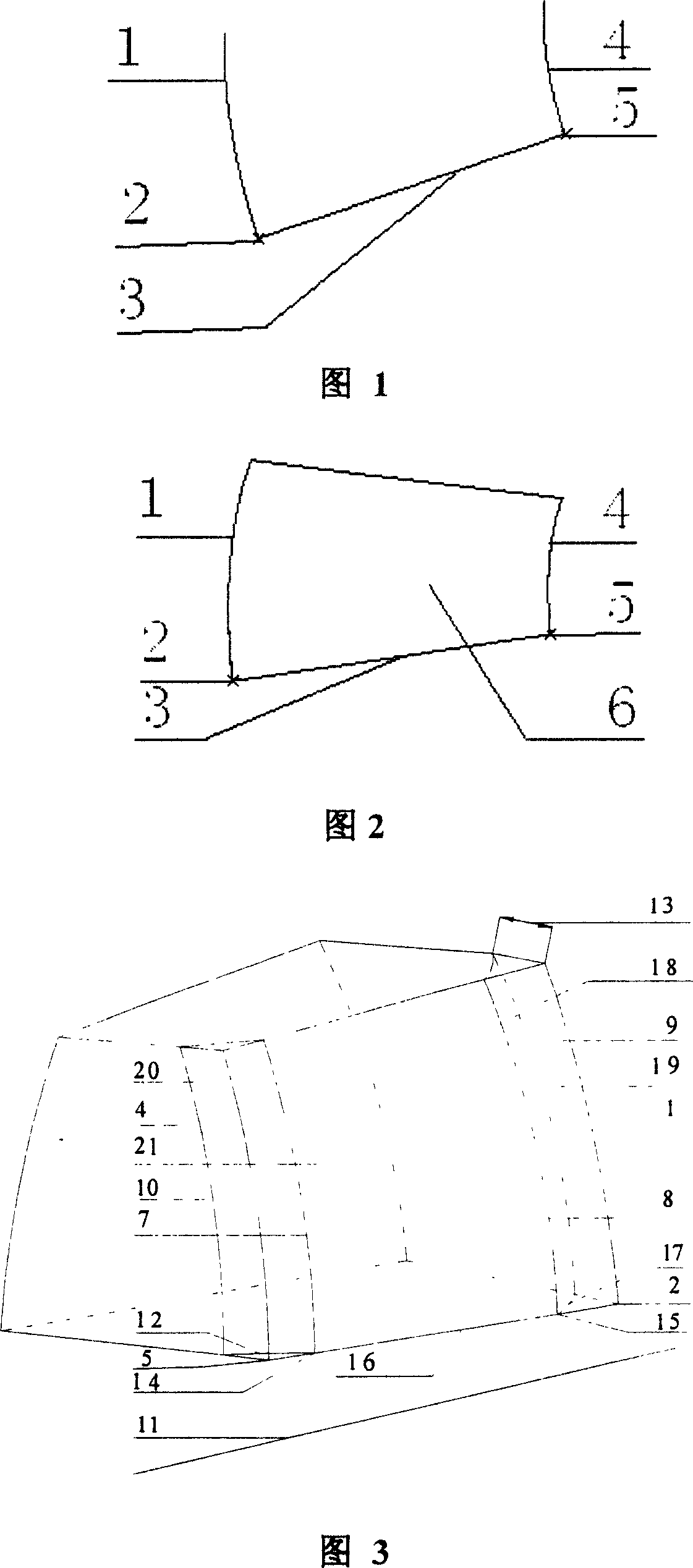

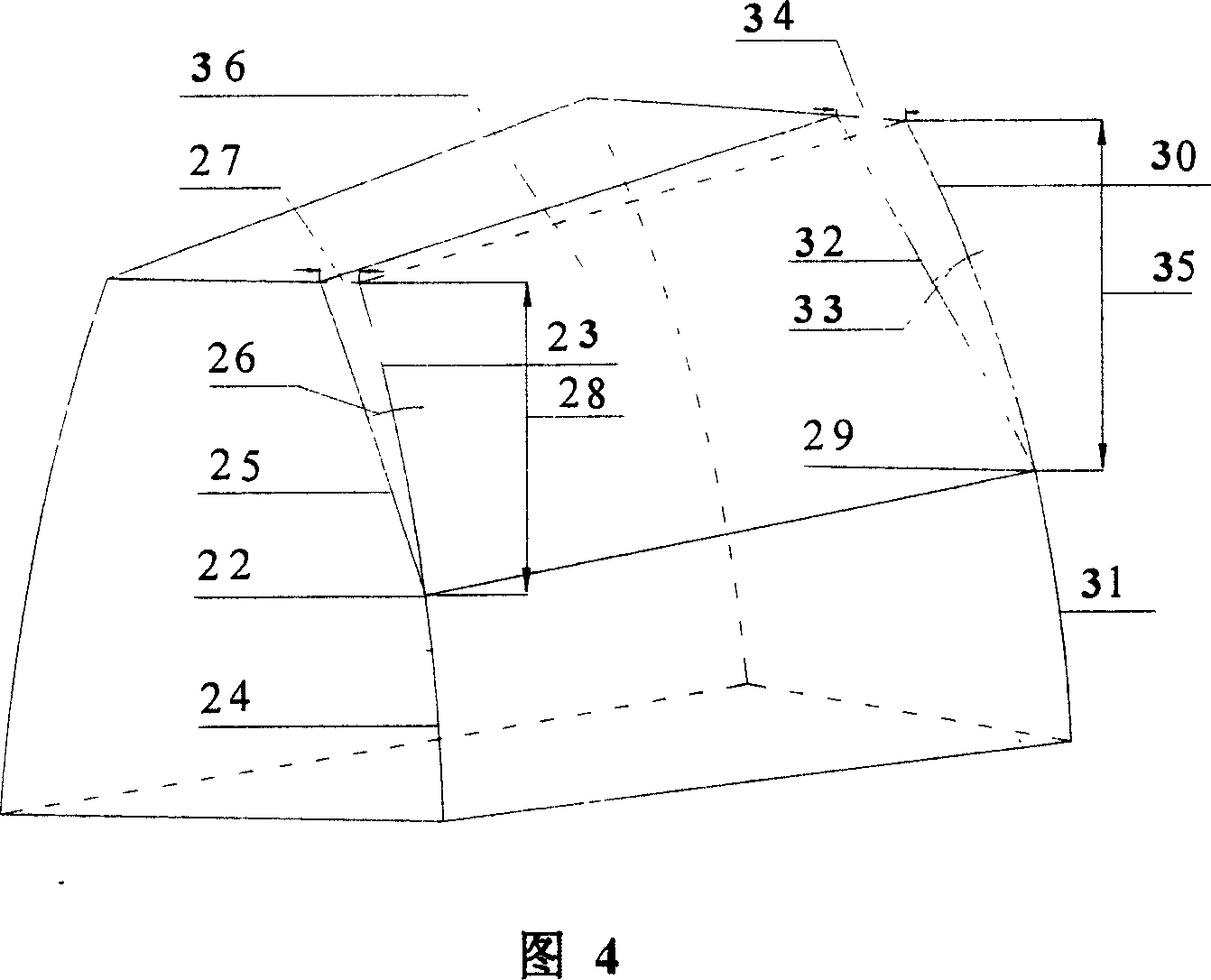

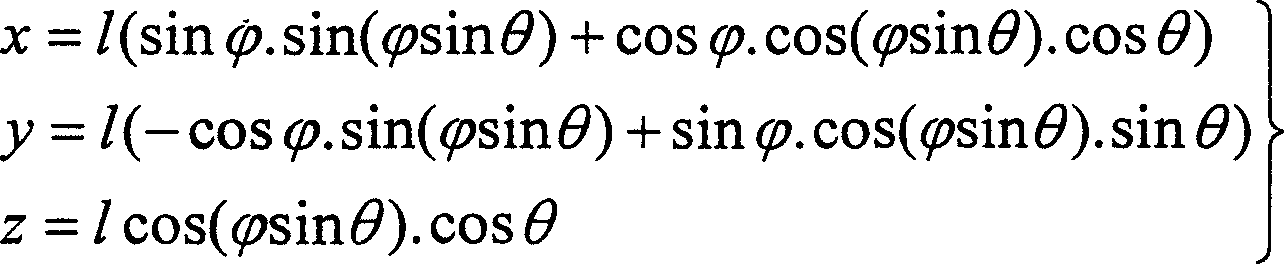

[0021] As shown in Figure 1-Figure 2, the involute of the big-endian theory is 1, the starting point of the involute of the big-endian theory is 2, the involute of the small-endian theory is 4, the starting point of the involute of the small-endian theory is 5, the big-endian and the small-endian The straight line formed by the starting points 2 and 5 in the same direction of the theoretical involute is the theoretical trajectory 3, any theoretical involute is used as the initial trajectory (Origin Trajectory), and the other theoretical involute is used as the control trajectory (X-Trajectory). Theoretical tooth surface 6 is obtained by variable section scanning method.

[0022] As shown in Figure 3, the tooth direction modification is performed on the theoretical trajectory of the gear; two theoretical involutes are established between the big-end theoretical involute 1 and the small-end theoretical involute 4: according to the small-end modification length Determine the theo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com