Novel tooth-shaped screw type wire

A screw profile and tooth shape technology, applied in liquid fuel engines, mechanical equipment, pumps, etc., can solve the problems of incomplete conjugation, exponential helix envelope and dedendum arc without specifying the transition form, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

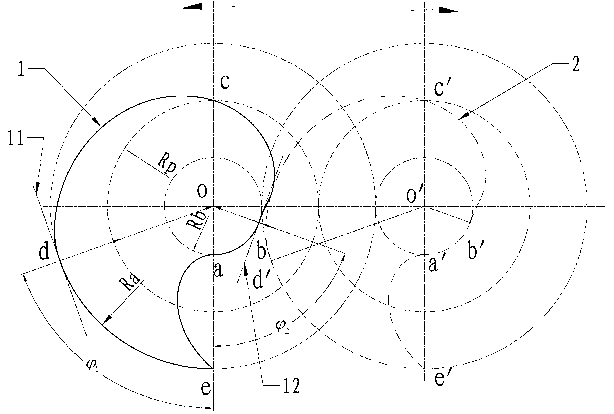

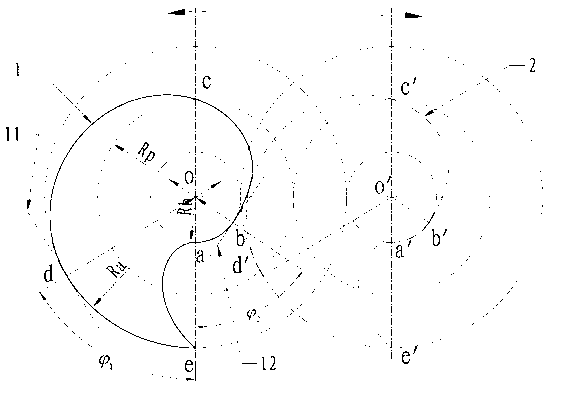

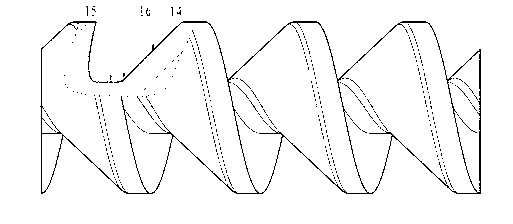

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

[0011] A new type of toothed screw profile, which is used for paired screws with parallel axes and reverse external meshing. The number of screw heads is greater than or equal to 2. It is characterized in that the two screws use the same end surface profile composed of five-segment curves. , as shown in Figure 1, screw 1 and screw 2 adopt the same five-segment end surface profile, which includes a section of root arc ab, a section of deformed involute bc, and a section of deformed involute b'c' is the envelope curve cd of the baseline, a section of addendum arc de, and a section of trochoid ea, the transition between the dedendum arc ab and the deformed involute bc is smooth, and the envelope cd and The tooth top arc transition is smooth.

[0012] In the embodiment of Fig. 1, when the two screws are in relative meshing and rolling, among the profile lines of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com