Scroll gas-liquid multiphase mixing transmission pump

A scroll-type, gas-liquid technology, used in rotary piston pumps, rotary piston/oscillating piston pump components, rotary piston machines, etc. problems, to achieve the effect of ensuring operational safety, high reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

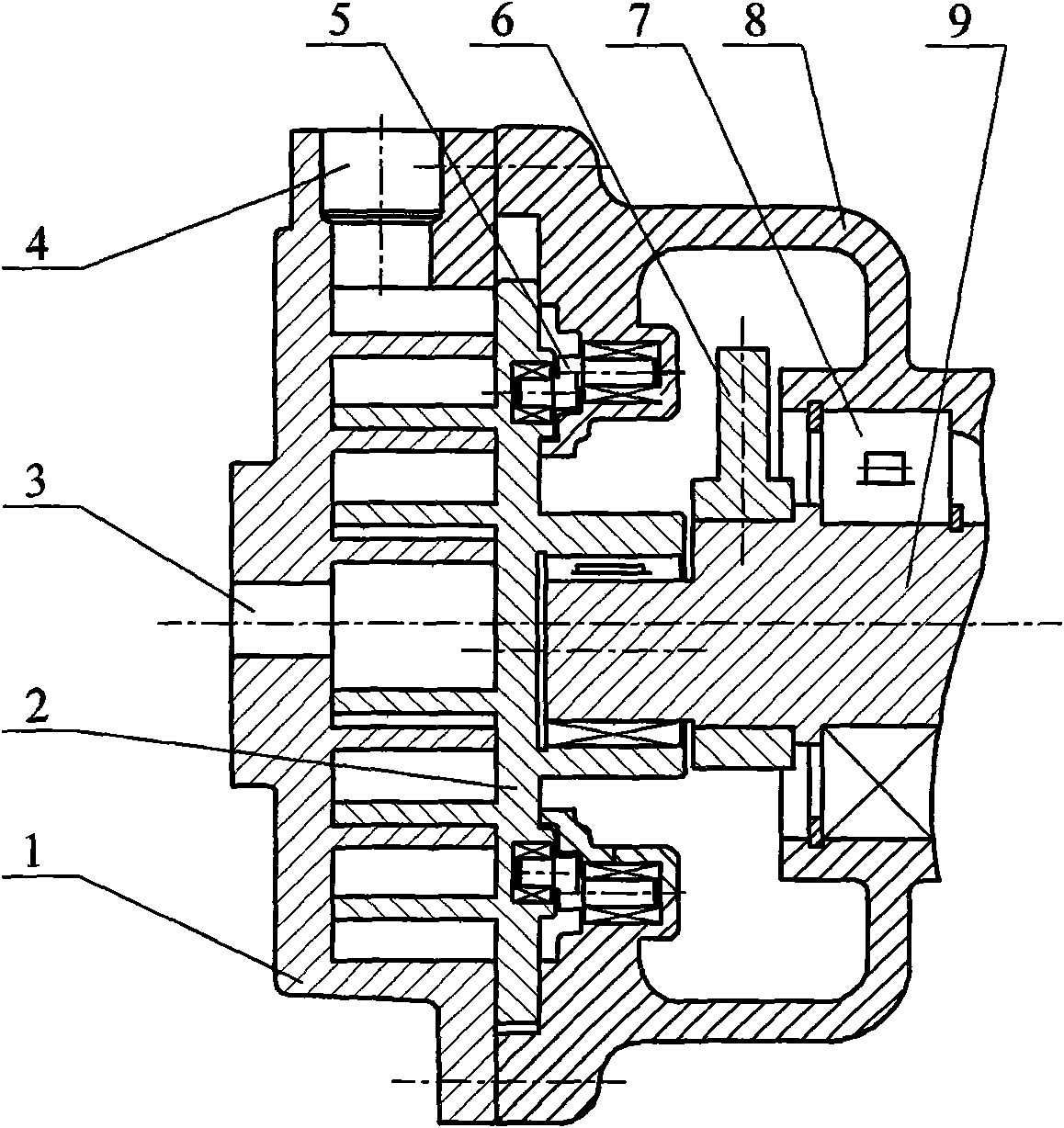

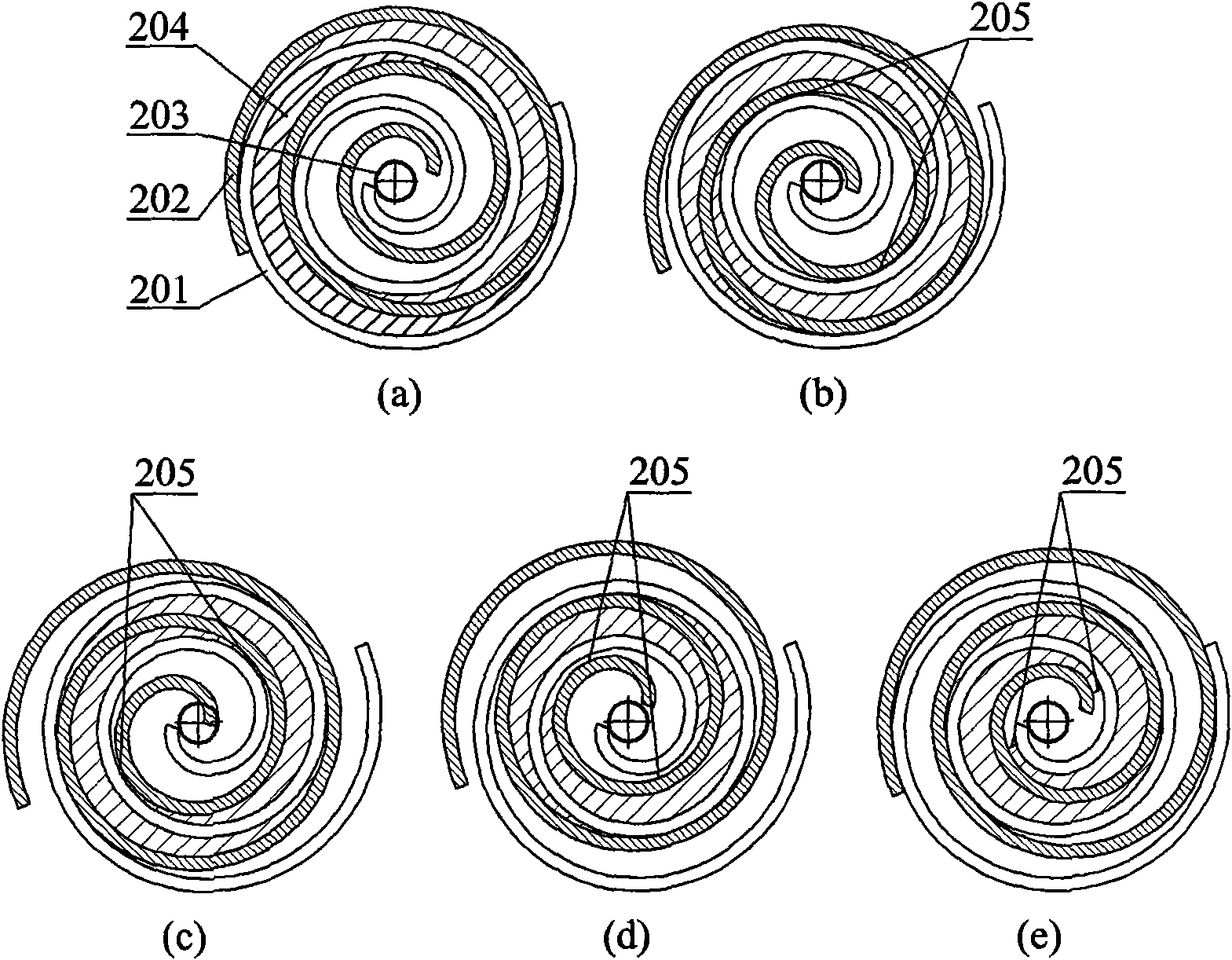

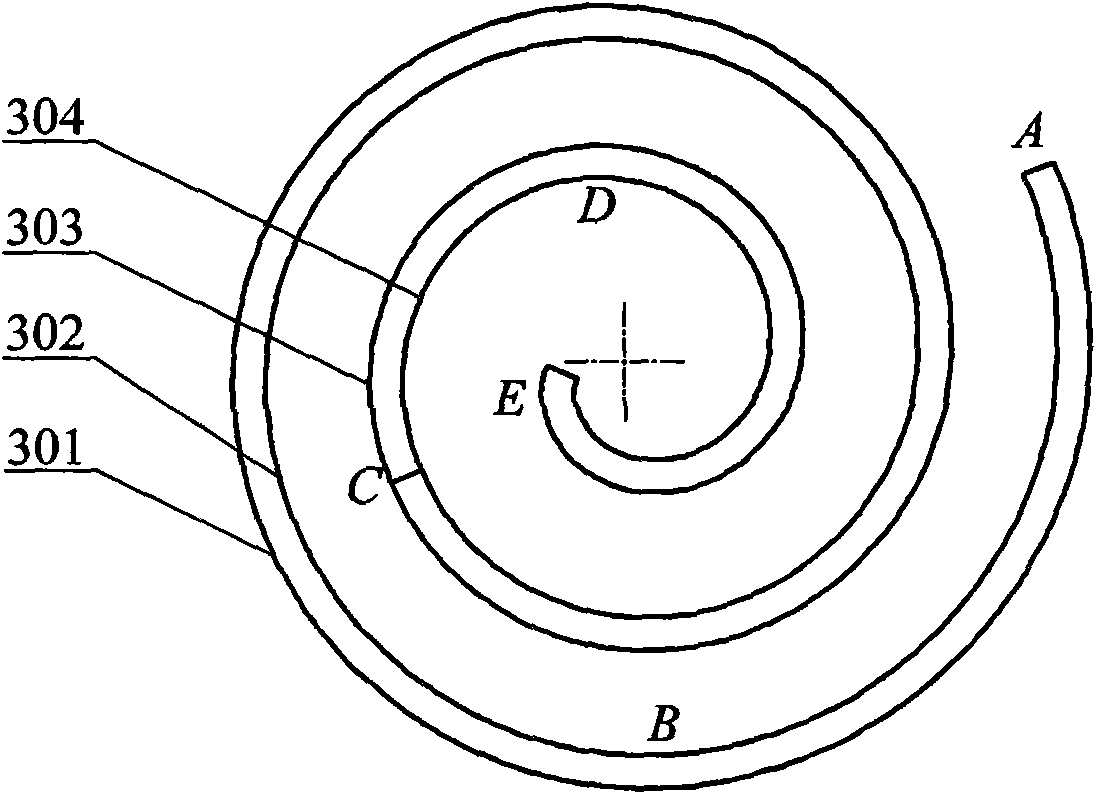

[0016] like figure 1 As shown, the scroll type gas-liquid multi-phase mixed transport pump is mainly composed of a static scroll 1, a movable scroll 2, a small bell crank anti-rotation mechanism 5, a bracket body 8, a crank shaft 9, a balance iron 6 and a bearing 7, etc. Composed of components, the circumference of the fixed scroll 1 is provided with a suction port 4, and the center of the fixed scroll 1 is provided with a discharge port 3. During the working process, the moving and static scrolls with the same profile rotate relative to each other for a certain angle and are offset by a certain distance before being inserted together to form two groups of crescent-shaped working chamber volumes. During the compression process, the formed compression chamber is It is composed of variable meshing gap profiles, so the formed compression chamber has an meshing gap in the direction leading to the discharge port, forming an internal leakage channel from the compression chamber to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com