Multi-axis drilling machine with adjustable interval

A multi-axis drilling machine and spacing adjustment technology, applied in boring/drilling, drilling/drilling equipment, metal processing equipment, etc., can solve the problems of low precision, inconvenient adjustment, large error, etc., to improve work efficiency , the effect of easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

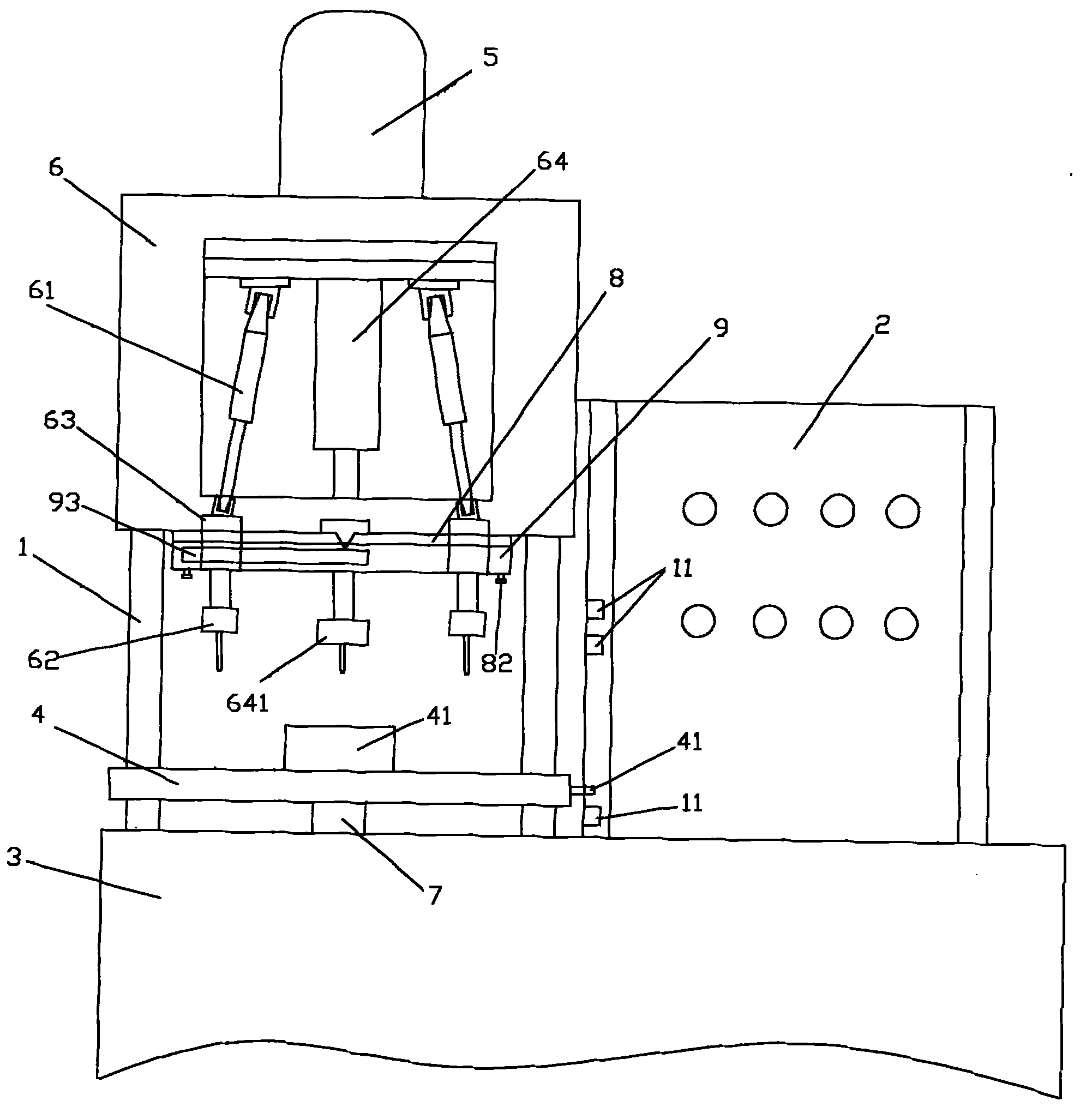

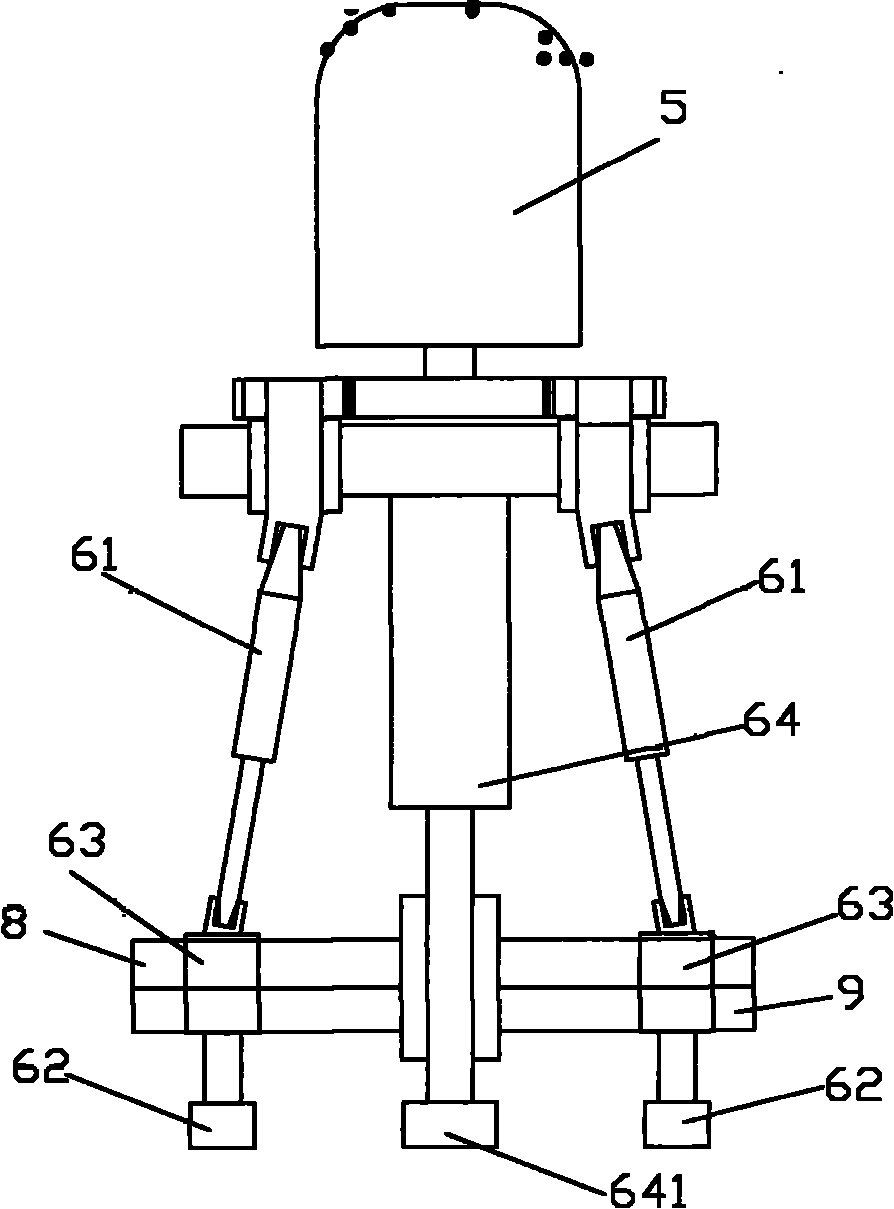

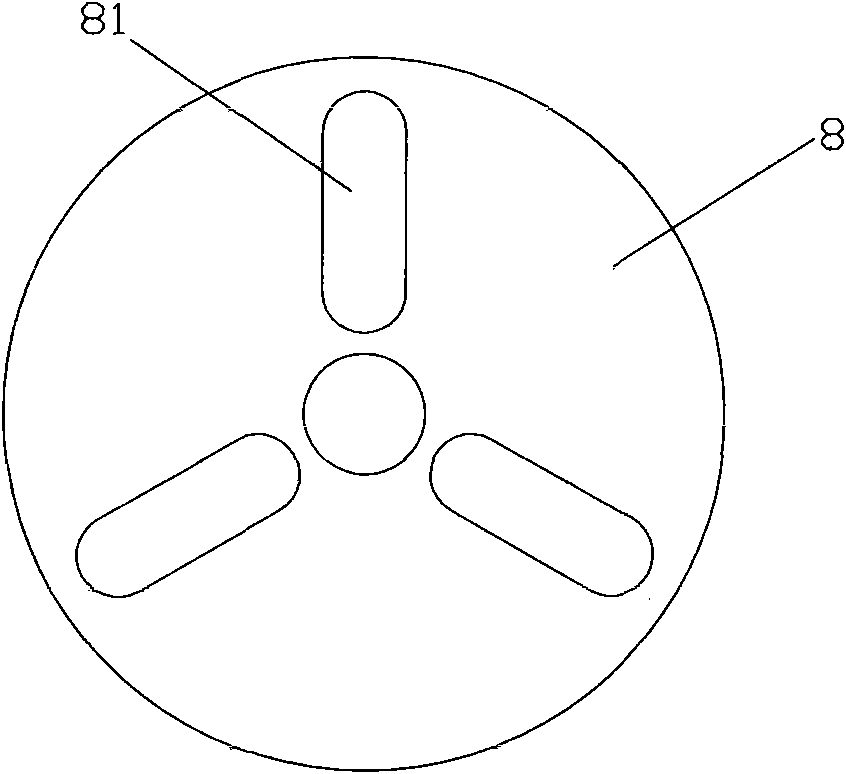

[0014] Such as Figure 1-4 As shown, a multi-axis drilling machine with adjustable spacing includes a machine body 1, a control box 2, a base 3, a workbench 4, a main motor 5 and a spindle box 6, and a workbench lift is provided between the workbench 4 and the base 3 Mechanism 7, headstock 6 is arranged on the fuselage 1 and is positioned at the top of workbench 4, described headstock 6 is provided with universal joint 61, and the upper end of universal joint 61 is connected with main motor 5 through gear or pulley. connection, the lower end of the universal joint 61 is connected with the drill spindle 62, a fixed adjustment plate 8 and a rotation adjustment plate 9 are arranged in turn at the bottom of the headstock 6, and a radial adjustment plate 8 is arranged on the fixed adjustment plate 8. The slot 81 is provided with an involute slot 91 corresponding to the radial adjustment slot 81 on the rotation adjusting plate 9 , and a positioning slot 92 is also provided on the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com