Method for supporting arch tire for building overhead brick in inclined duct of dry quenching furnace

A technology for chute area and dry quenching furnace, which is applied in construction, coking oven, building structure, etc. It can solve the problem that the flatness cannot meet the direct installation of wooden frames, increase the amount of steel pipes and construction procedures, and the height of wooden frames cannot be predicted in advance, etc. problems, to achieve the effect of reducing the supporting process, simplifying the masonry, and saving the amount of steel pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

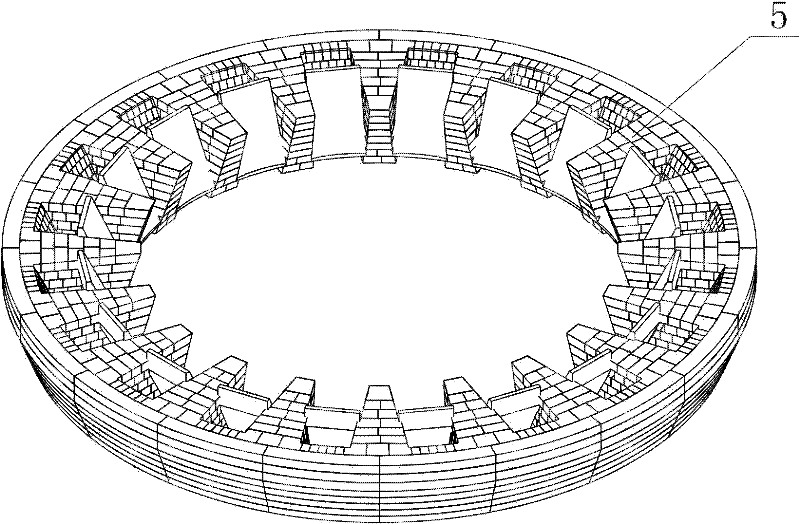

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

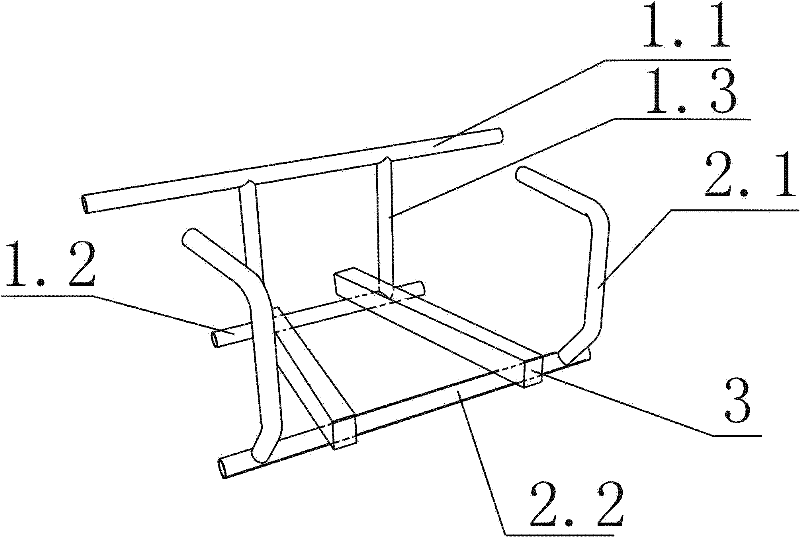

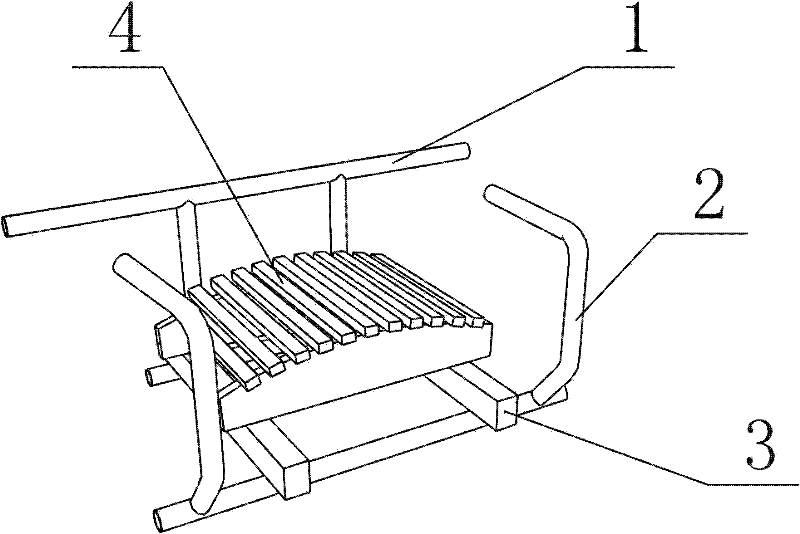

[0023] see figure 1 , making a special device for arch tire support

[0024] The special device for supporting the arch tire includes a rear support 1, a front support 2 and a wooden bracket 3; the rear support 1 includes two upper cross bars 1.1 and lower cross bars 1.2 with different lengths and arranged in parallel, and connecting the two cross bars The connecting rod 1.3, the length of the upper cross bar 1.1 is greater than the length of the lower cross bar 1.2, and there are two connecting rods 1.3, and the two connecting rods 1.3 form a square frame with the upper cross bar 1.1 and the lower cross bar 1.2 Structure; the front bracket 2 includes two C-shaped curved rods 2.1, and a cross bar 2.2 connecting the two curved rods 2.1; the wooden support 3 is two wooden rods with a square cross section; the One end of the wooden stick is placed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com