Method and device for measuring oil-water content in oil storage tank

A measuring device and technology of oil-water content, which is applied in the field of oil-water interface, oil-water content in crude oil storage tanks, and crude oil water content measurement fields, which can solve the unfavorable fire and explosion prevention safety of oil tank farms, increase the installation opening of measuring equipment, and high measurement cost, etc. problem, to achieve the effect of simple structure, simple structure and simple calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

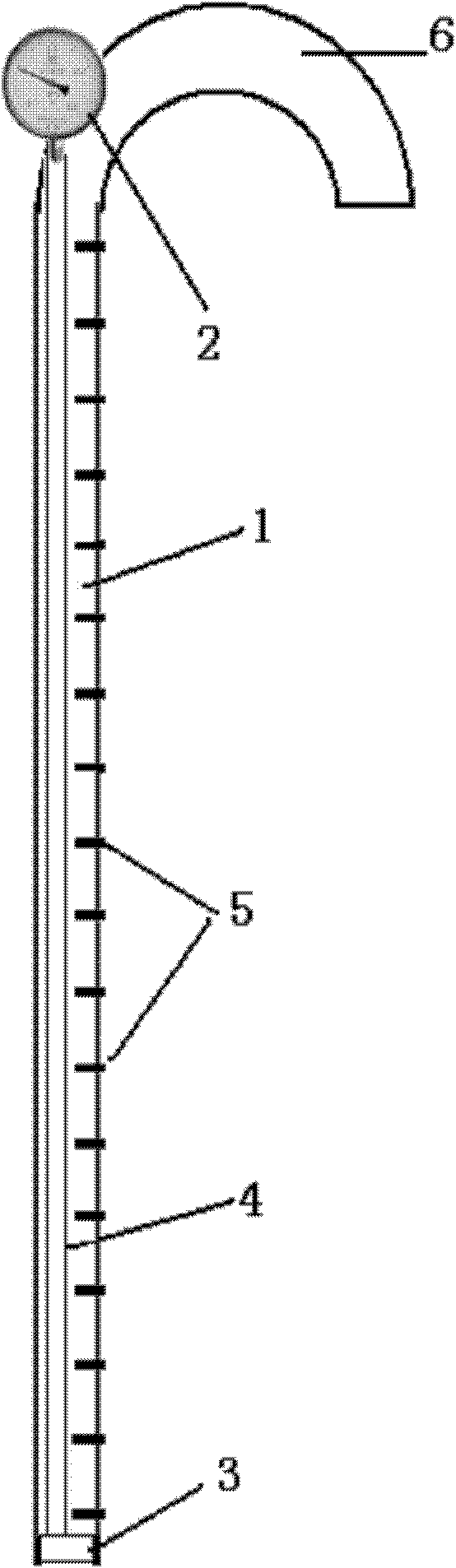

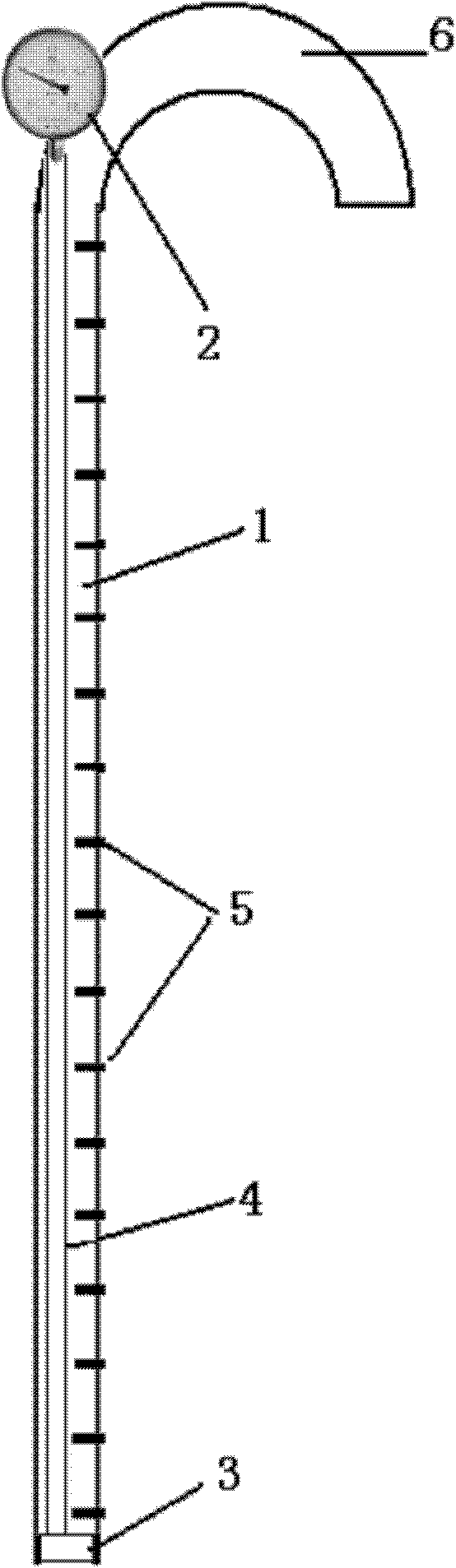

[0025] As shown in the drawings, the oil-water content measuring device in the oil storage tank has a pressure gauge 2 in the hollow cylinder 1, the test head 3 of the pressure gauge 2 is located at the bottom opening of the cylinder 1, and the display head of the pressure gauge 2 Located at the top opening of the cylinder body 1, the connecting line of the display head of the pressure gauge 2 and the test head, that is, the pressure line 4 is located inside the cylinder body 1, and there is a scale 5 on the outer wall of the cylinder body 1. The top of the barrel 1 is a handle 6, and the display head of the pressure gauge 2 is located on the handle 6. The bottom opening is located on the bottom of the cylinder 1 or on the side of the bottom of the cylinder 1 , and when located on the bottom of the cylinder 1 , the bottom opening is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com