Laser-ray-following wall ground leveling darby

A technology of scraper and short scraper, which is applied in the direction of construction and building structure, can solve the problems of waste of aluminum materials, difficulty in leveling walls and floors accurately, and small application range of aluminum alloy leveling scraper construction, so as to achieve convenient portability and leveling Accurate, extended range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] (1) Workshop: 200 square meters.

[0053] (2) Overall production process: cutting—grooving—board reduction—bending—drilling—grinding—assembly—inspection—packaging—storage.

[0054] (3) Production equipment:

[0055] Laser cutting machine, profile cutting machine, planer, sand mill, shearing machine, bending machine, bench drill.

[0056] (4): Parts assembly:

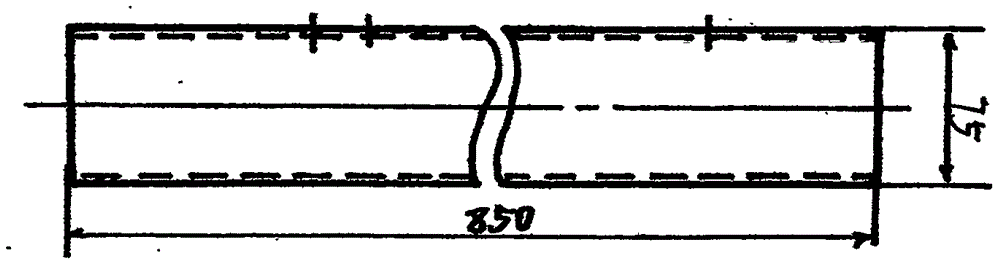

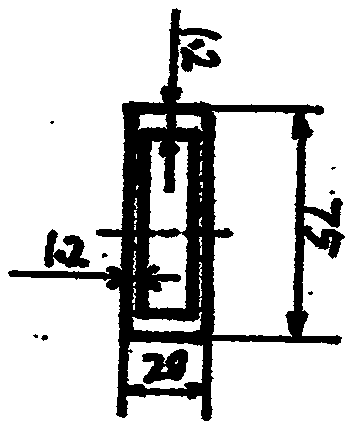

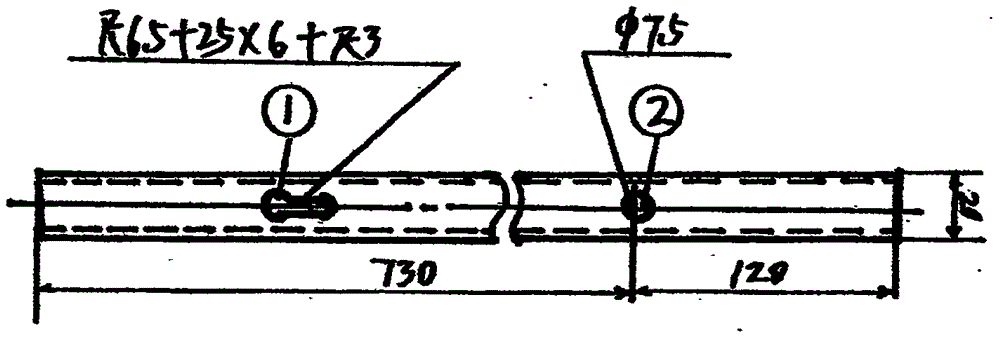

[0057] The first step: ordering and processing Figure 1-Figure 24 tool parts.

[0058] Step 2: Multifunctional U-shaped connector assembly ( Figure 25 ):

[0059] According to the direction of the arrow ⑤⑦, put the two blocks into the U-shaped groove ①, align the two holes of the block with the two holes ②③, fix them with super glue, and assemble Figure 26 ① configuration.

[0060] Step 3: L-shaped adjustable ruler assembly storage assembly diagram ( Figure 26 ):

[0061] Put two L-shaped adjustable ruler components, ( Figure 26 ②③), into the plug ( Figure 26 ①) In the U-shaped bucket, put the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com