Installation method of ring seam scrubbing tower AGE tube

A ring seam washing and installation method technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as difficult control, achieve convenient operation, avoid secondary rework, and ensure concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

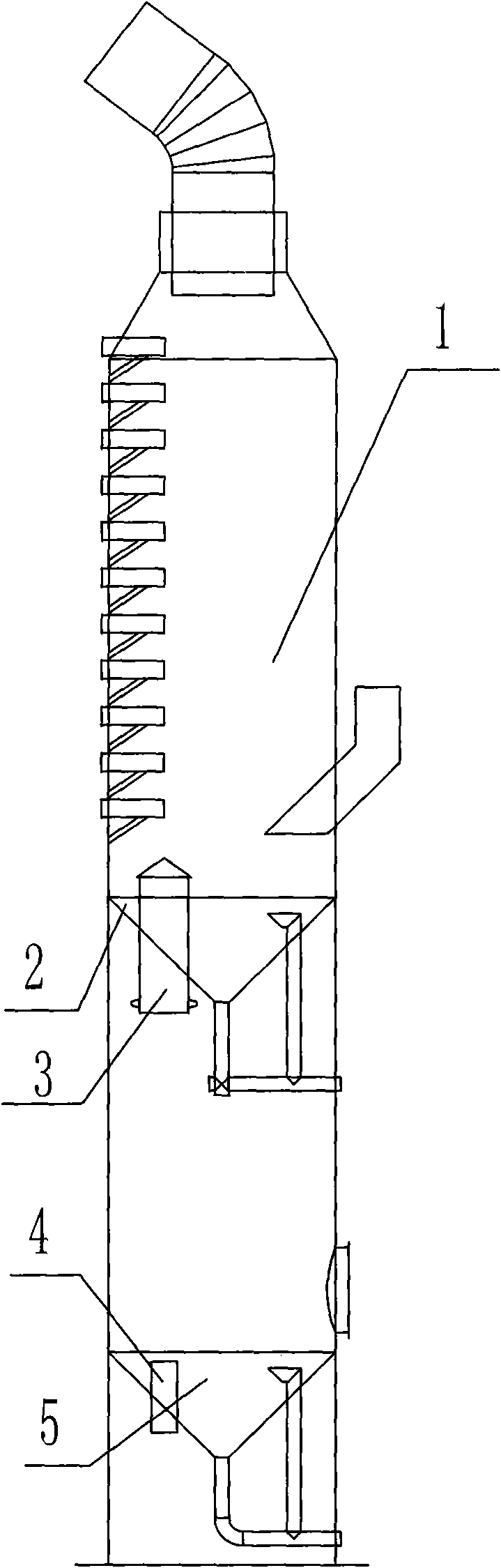

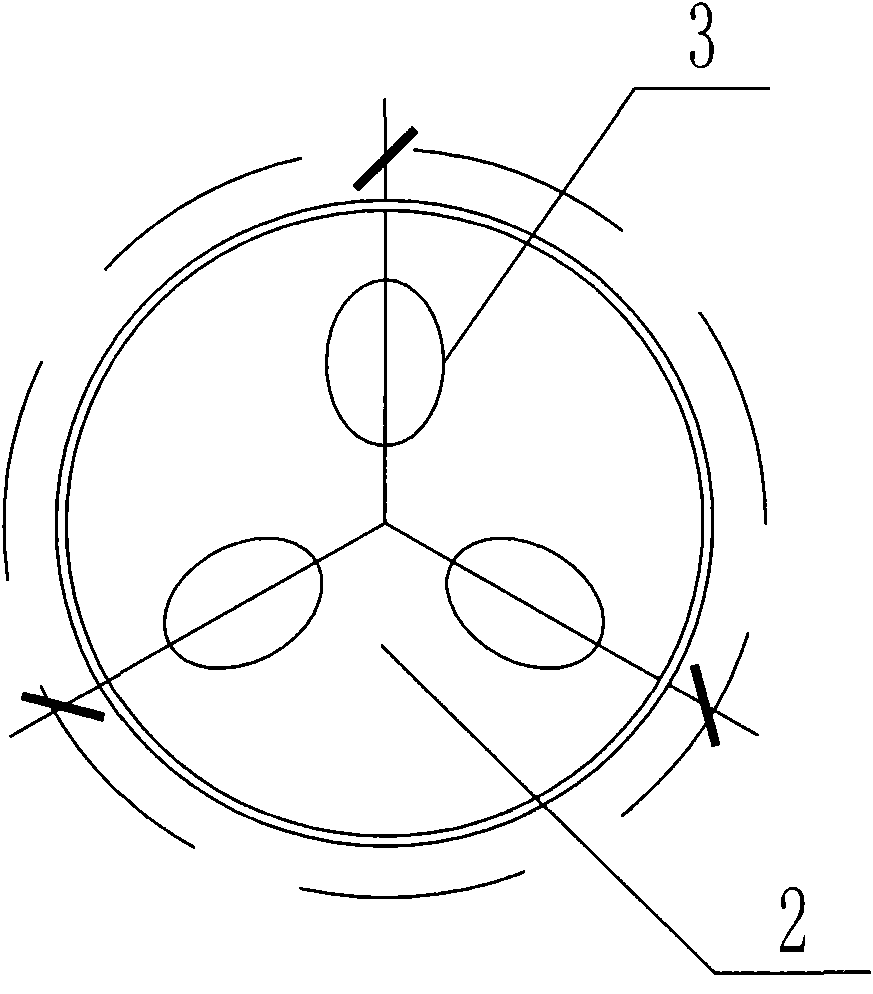

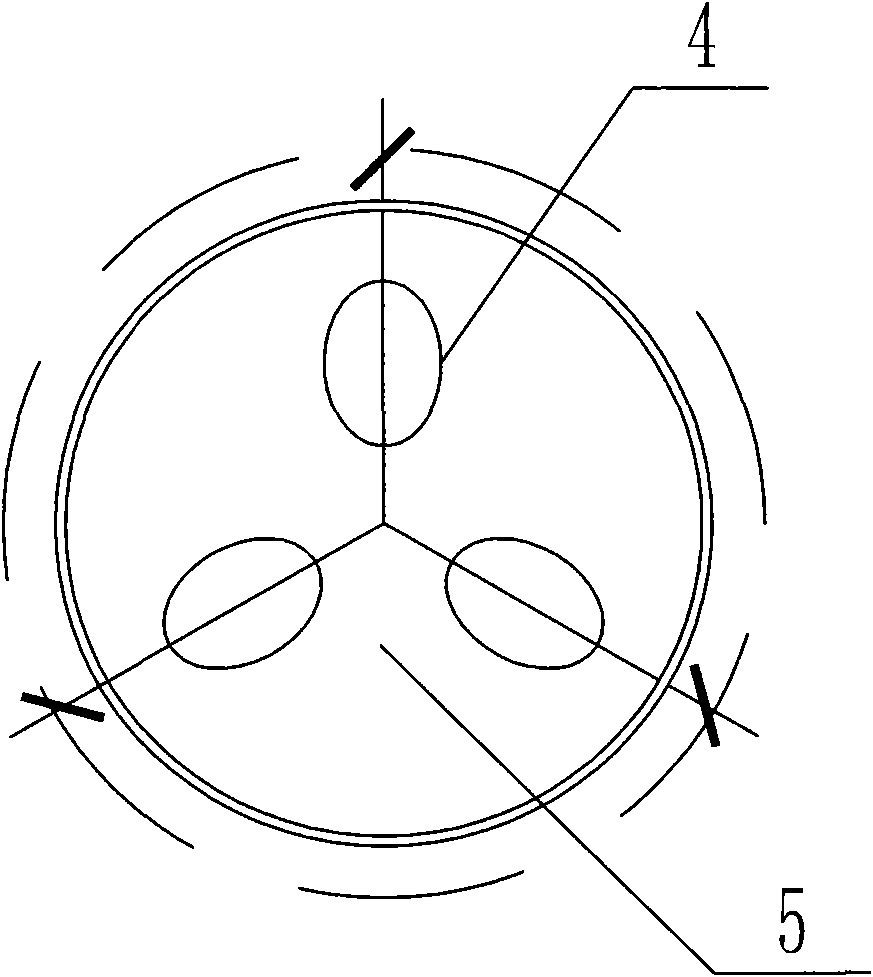

[0024] See attached Figure 1-8 , in this embodiment, the existing annular seam washing tower 1 is generally a cylindrical structure, and an upper cone 2 and a lower cone 5 are installed inside it. The conduit adopts an AGE conduit, and the upper cone 2 is installed on the upper cone. Conduit 3, the conduit installed on the lower cone 5 is the downcomer 4, and the bottom of the washing tower 1 is also provided with a concrete foundation 7. Three upper conduits 3 and three lower conduits 4 are respectively installed on the upper and lower cones, and the angle between each pair of the upper and lower conduits 3 and 4 is 120°. It is also necessary to ensure that the corresponding upper and lower conduits are installed The concentricity, elevation and verticality of the

[0025] The present invention carries out the installation and adjustment of condui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com