Novel process of medium-pressure ammine recovery system for urea water solution complete cycle production

A urea aqueous solution and full cycle technology, which is applied in the preparation/separation of ammonia, preparation of urea derivatives, chemical instruments and methods, etc., can solve the problems of increased venting volume, increased absorption tower load, and poor heat transfer effect, etc., to achieve Effects of reduced power consumption, reduced number of operations, and reduced water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

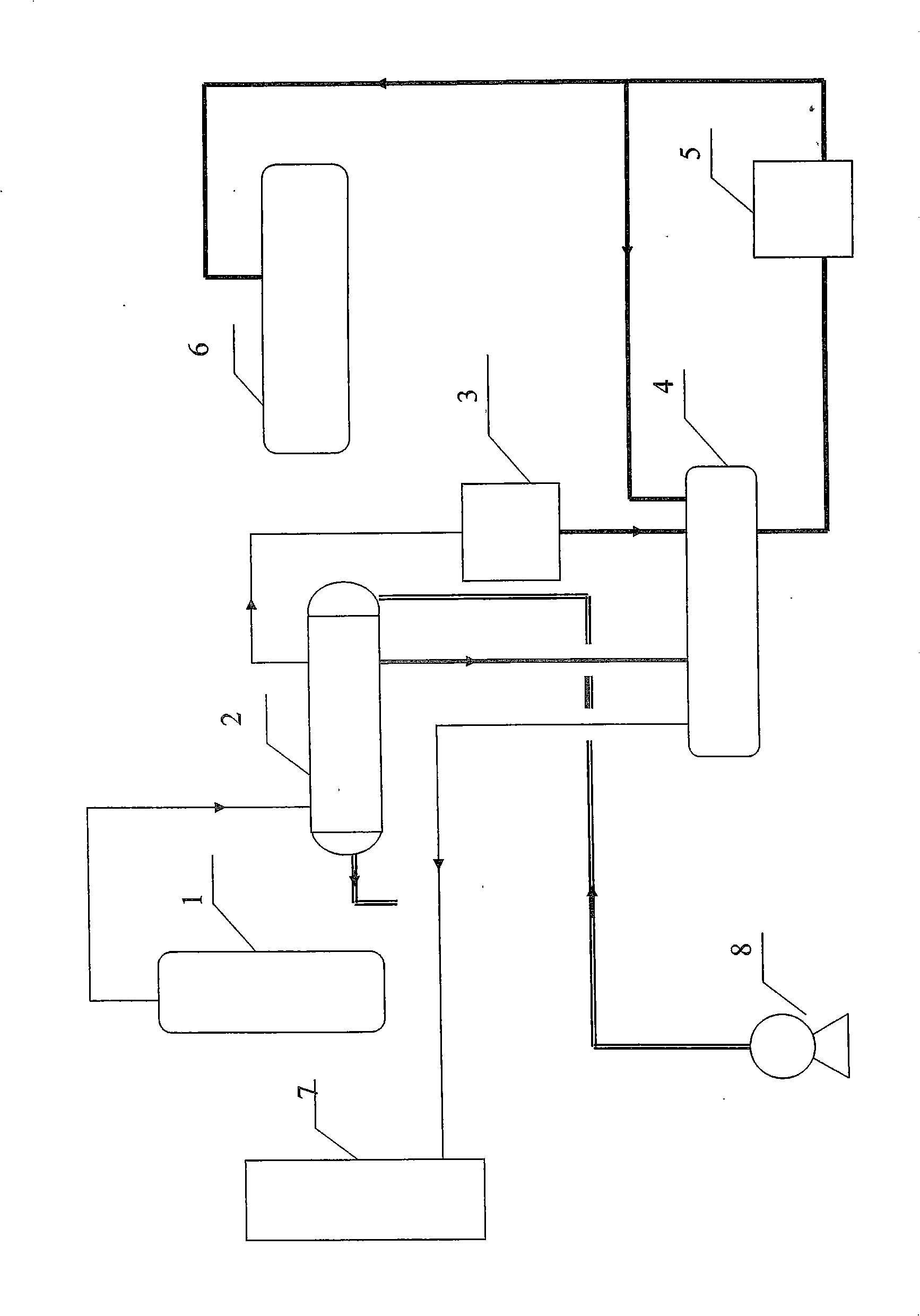

[0016] A new process for producing a medium-pressure ammonia recovery system with full circulation of urea aqueous solution, which consists of a suction tower (1), an ammonia condenser A (2), an evaporative condenser (3), an ammonia storage tank (4), and an ammonia pump (5), medium-pressure liquid ammonia buffer tank (6), inert washer (7), circulating water pump (8), equipment and equipment are connected with pipelines, and the elevation of ammonia condenser A is reduced in the new process at the same time, It is equipped with a corresponding circulating water pump.

[0017] The process flow of the present invention is: the gas from a suction tower (1) enters between the tubes of the ammonia condenser A (2), the ammonia in the gas is condensed, flows into the liquid ammonia storage tank (4), and the gas from the ammonia condenser enters In the tubes of the evaporative condenser (3), the ammonia in the gas is condensed into liquid ammonia, and then flows into the liquid ammonia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com