Walking beam changing method of step-by-steep heating furnace

A technology of walking heating furnace and replacement method, applied in lighting and heating equipment, furnace, furnace components and other directions, can solve the problems of affecting production capacity ratio, high replacement cost, bending deformation of column, etc., to increase product efficiency and reduce Maintenance costs, the effect of improving the production capacity ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

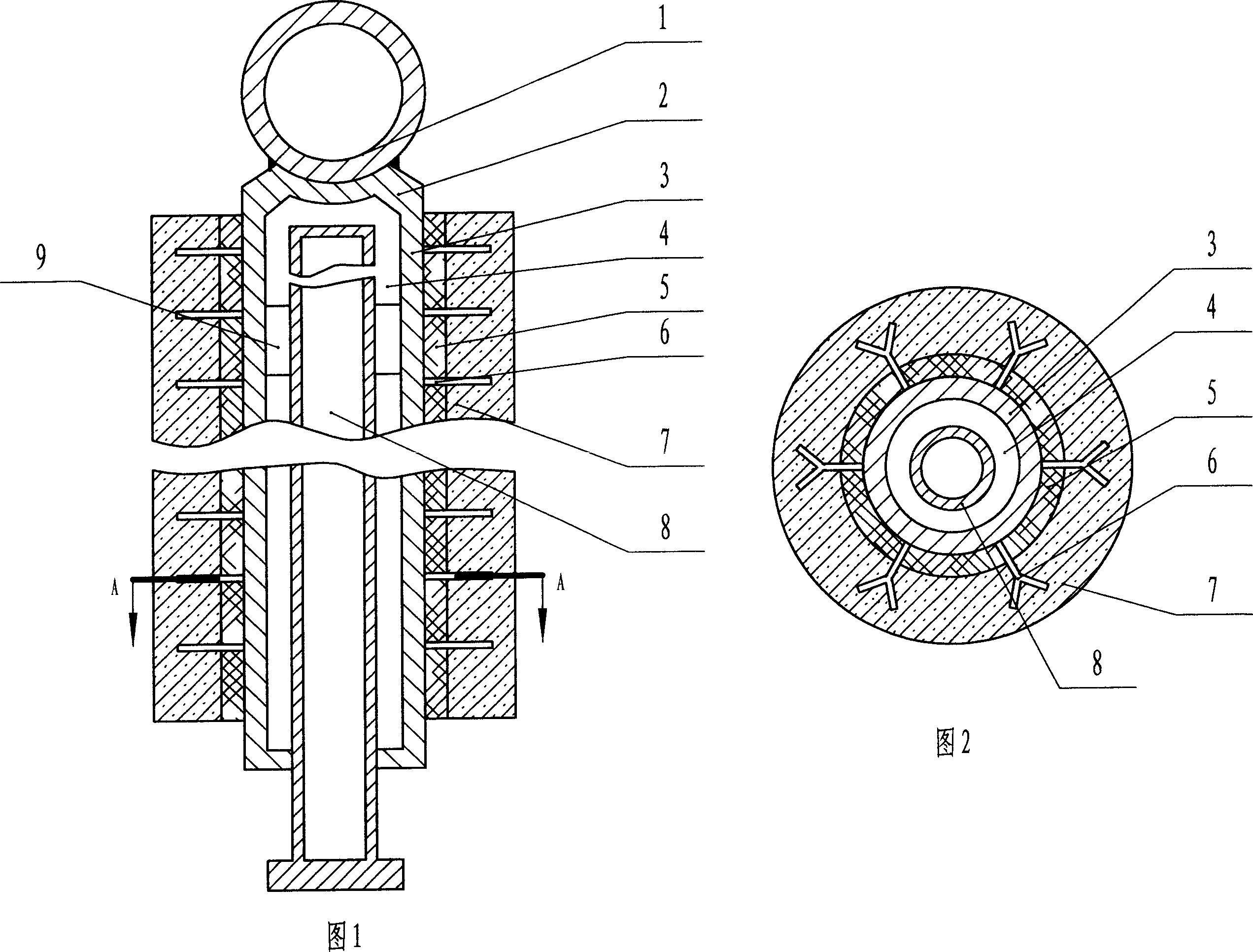

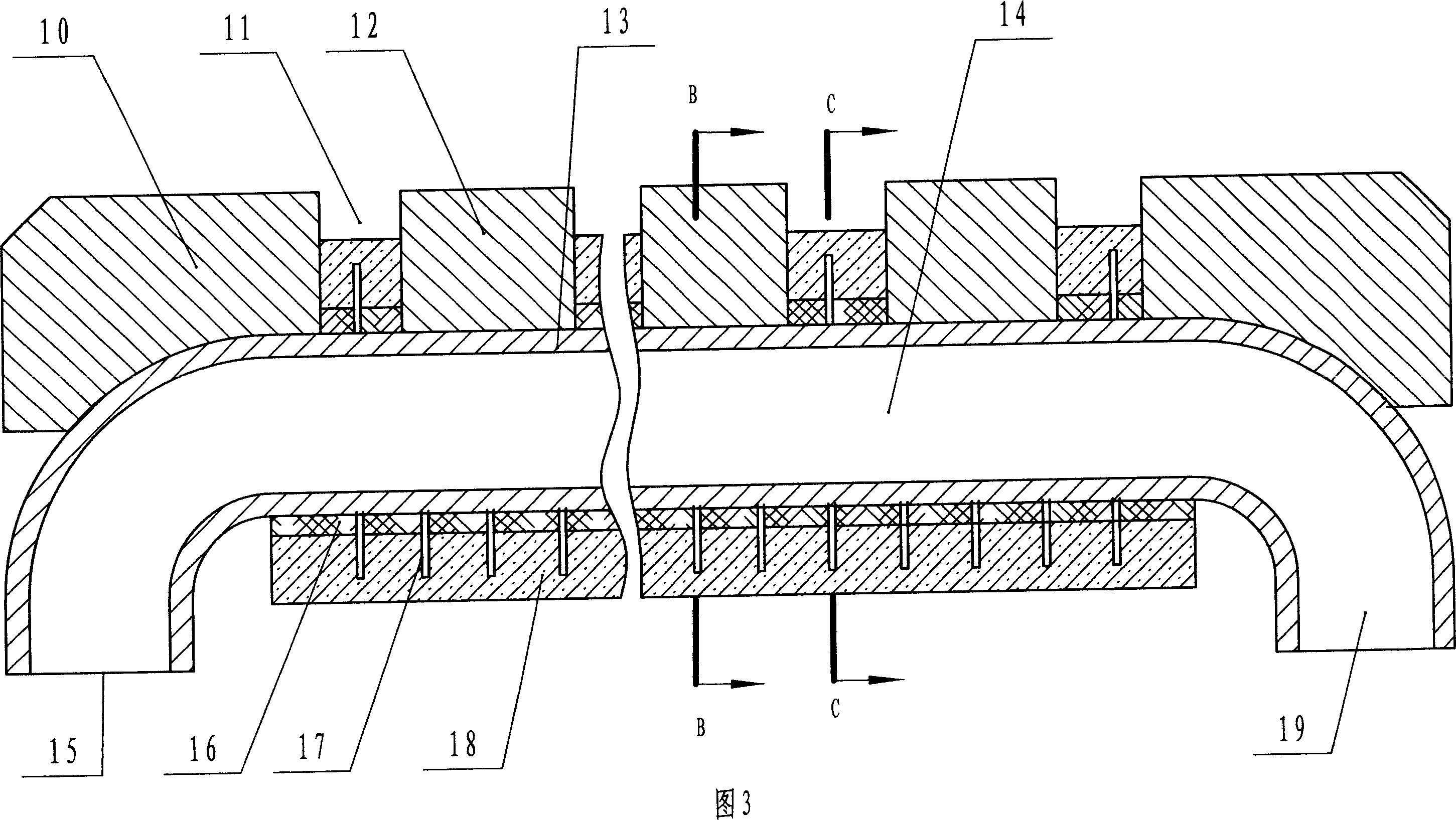

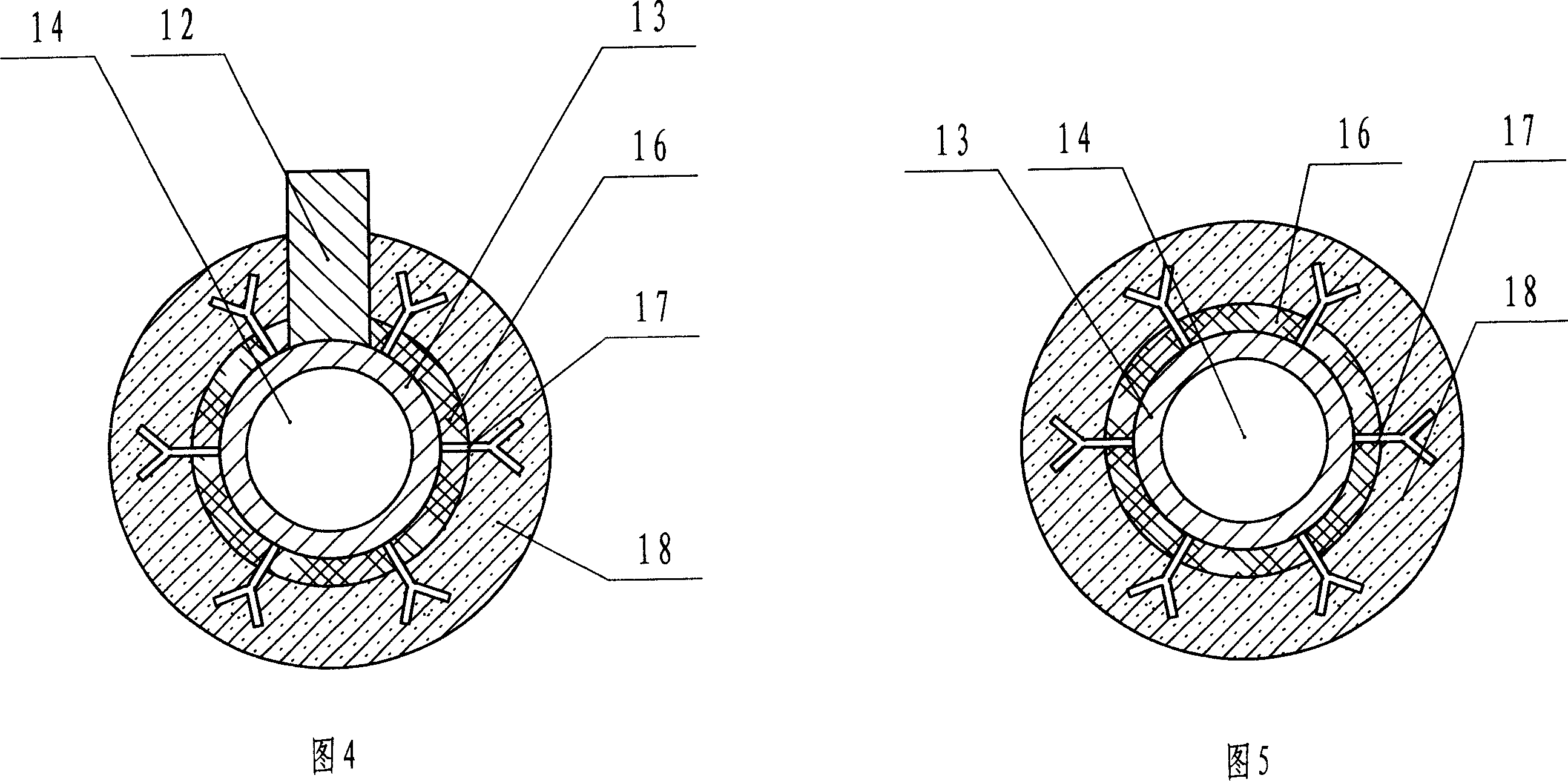

[0061] The specific implementation of the method for replacing the walking beam of the walking heating furnace will be described in detail below in conjunction with the embodiments and accompanying drawings, but the method for replacing the walking beam of the walking heating furnace is not limited to the following embodiments.

[0062] In this embodiment, a walk-in heating furnace with a length of 35m and a width of 9.4m is replaced. The length of the flame section is 23m, the length of the movable horizontal beam is 35m, the length of the movable horizontal beam of the flame section is 23m, the length of the fixed horizontal beam of the flame section is 23m, and the height of the column of the fixed beam 2.2m, the horizontal beam water pipe is 15000 mm long, the outer diameter is Φ163 mm, and the thickness is 20 mm. The movable beam column water pipe is 4389 mm long, the outer diameter is Φ163 mm, and the thickness is 20 mm.

[0063] The walking heating furnace column describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com