Construction method of in-service oil and gas pipelines encountering goaf collapse and damage

A technology of oil and gas pipelines and construction methods, which is applied in pipeline systems, pipeline laying and maintenance, pipe components, etc., can solve problems such as endangering pipeline safety, endangering the life and property safety of pipelines and nearby people, and surface subsidence, so as to reduce risks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

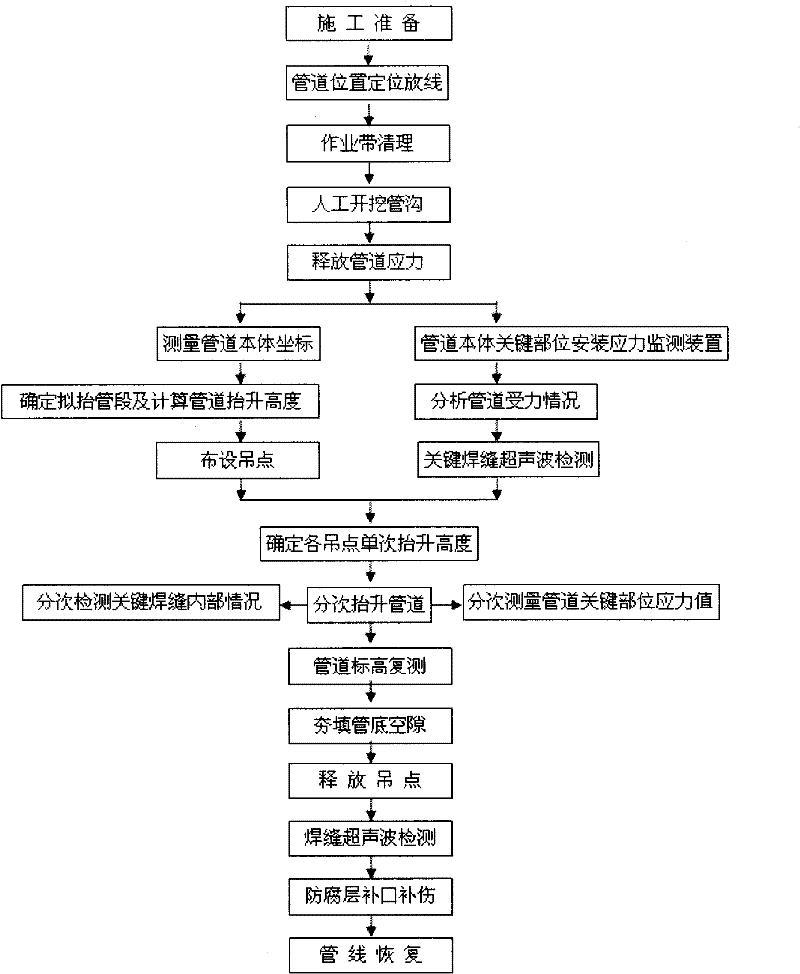

[0119] Embodiment. With this example, it is the test method to the gob control project of the Haoyu village coal mine of the West-to-East Gas Transmission Project. The length of the lifting pipe is 466m, and the maximum height of the lifting is 1.35m. Its flow process is as follows figure 1 shown.

[0120] The technological process of the pipe lifting construction method is as follows:

[0121] 1. Construction preparation;

[0122] 1.1 Various technical parameters of the pipeline body;

[0123] The parameters of the hoisted pipeline itself are:

[0124] outer diameter

wall thickness

Weight per linear meter

1016mm

17.5mm

430.93kg / m

[0125] 1.2 Materials

[0126] The main materials of this project include medium and coarse sand, straw bags, thermal insulation quilts, sleepers, etc. The specific plan is shown in the table

[0127] Main material demand schedule

[0128] serial number

unit

Specificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com