Crane beam scale height regulation method

An adjustment method and a technology of driving beams, which are applied in the direction of hoisting devices, lifting frames, load hanging components, etc., can solve problems such as difficulty in height adjustment, great influence of driving beams, and inability to meet use requirements, and achieve the effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

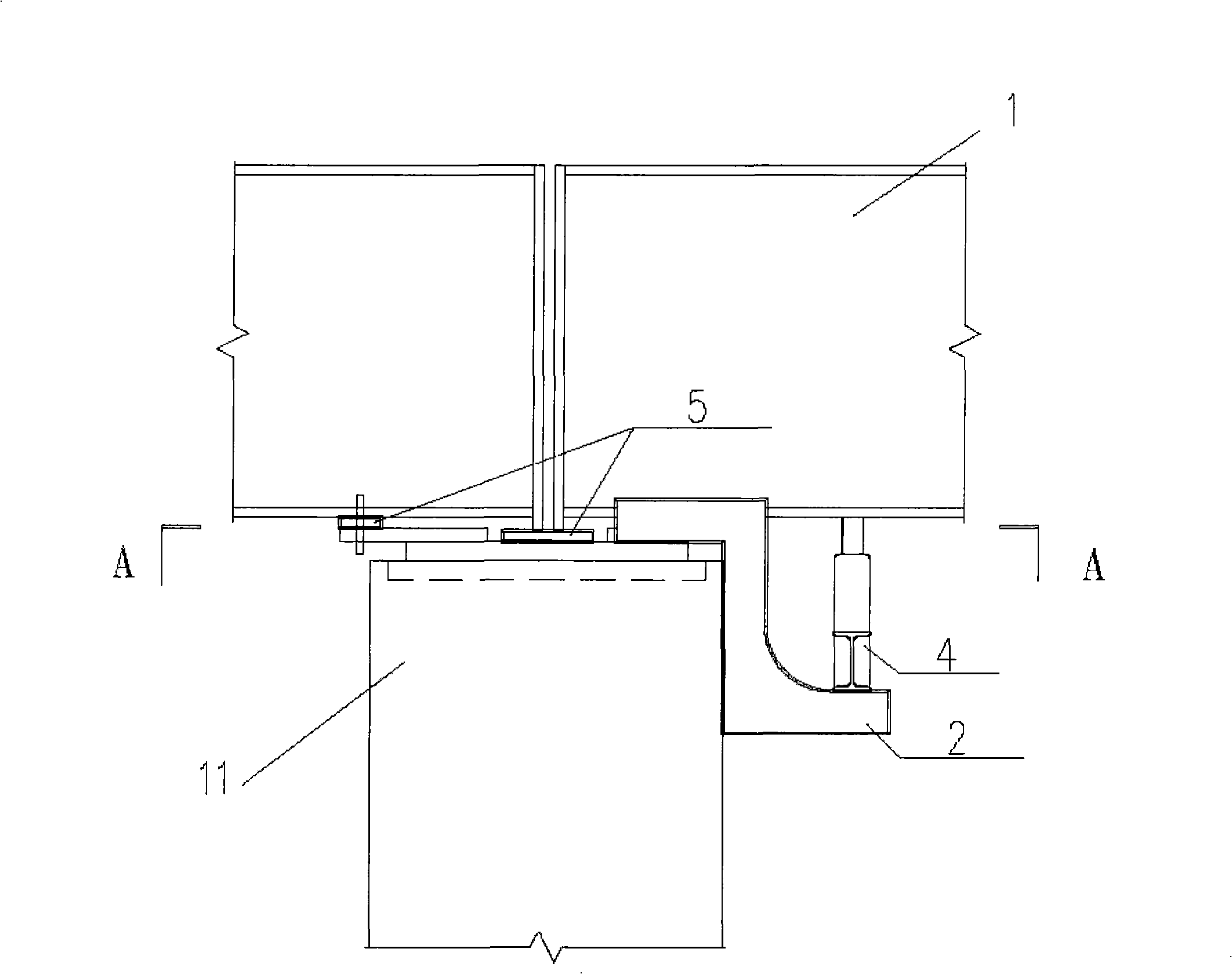

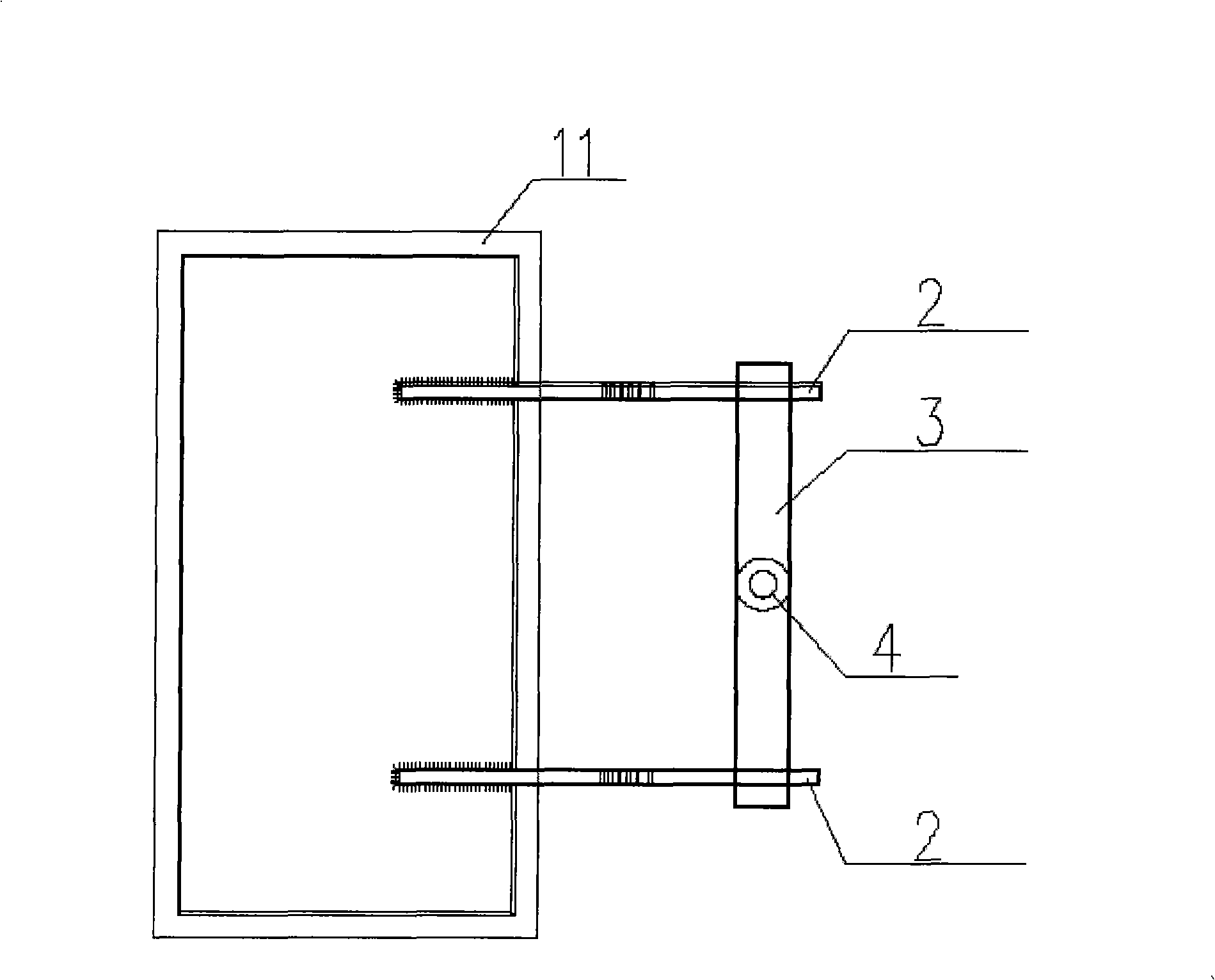

[0021] Such as figure 1 with figure 2 As shown, a method for adjusting the elevation of a driving beam includes: a driving beam 1 erected on a column 11, and the ends of adjacent driving beams 11 have spring plates and are connected by bolts; it includes the following steps

[0022] Step 1: Carry out a comprehensive measurement of the driving beam 1. The measurement content mainly includes the straightness of the driving beam, span, and top elevation. The measurement data must be sorted out before the adjustment of the driving beam, and the deviation value of the adjustment of the driving beam must be calculated and reviewed;

[0023] Step 2: Loosen the bolts connecting the driving beam and the spring plate;

[0024] Step three, erecting a crane elevation adjustment device; the adjustment device mainly includes a jack 4;

[0025] Step four: use the jack 4 to lift the driving beam 1 until the specified jacking adjustment value is reached.

[0026] The driving beam elevation adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com