Method for manufacturing and mounting irregular abnormally-shaped large space steel structure

An installation method and steel structure technology, applied in the field of construction production and metallurgy, can solve the problems of labor, mechanical work waste, material loss, and component damage, etc., to reduce labor intensity, reduce material loss, production and The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

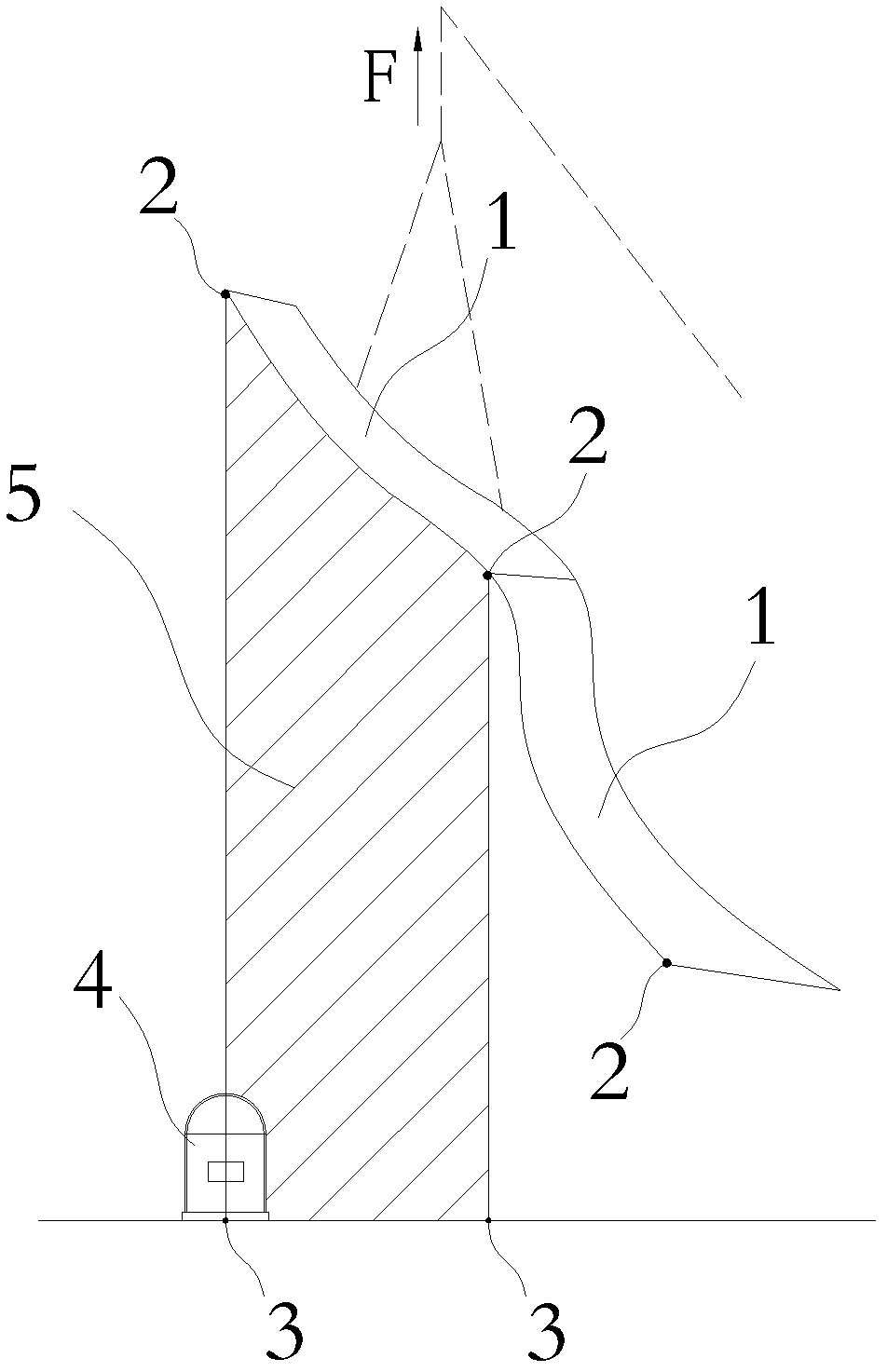

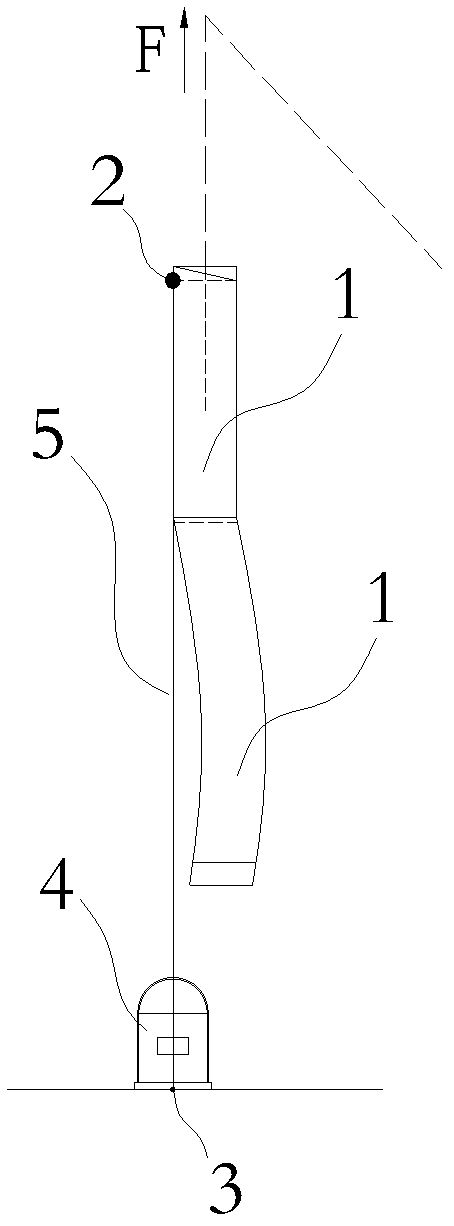

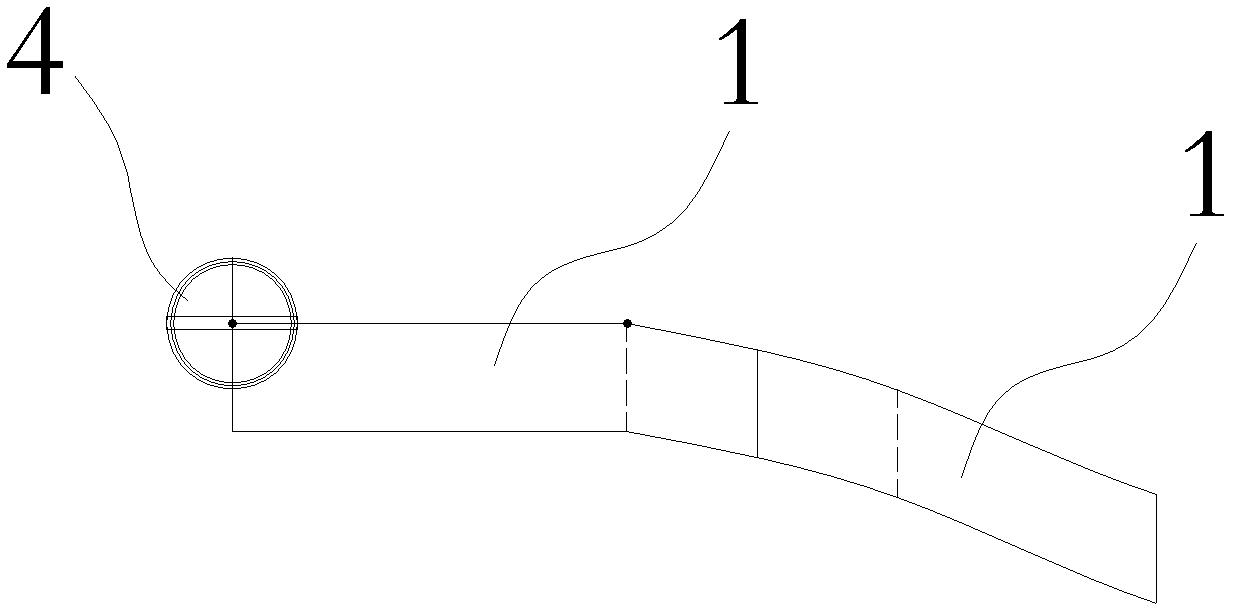

[0021] Such as figure 1 , figure 2 as well as image 3 Shown is a method for manufacturing and installing an irregular special-shaped large-space steel structure with high installation quality, convenient operation, and low labor intensity provided by the present invention. The method for making and installing includes the following steps,

[0022] 1) Determine the installation plan and installation sequence, and determine the installation plan and installation sequence according to the characteristics of the irregular and special-shaped large-space steel structure;

[0023] 2) Determine and draw the steel structure manufacturing unit diagram, according to the determined installation plan and installation sequence, take the nodes of the irregular and special-shaped large-space steel structure as the installation control point, determine the steel structure manufacturing unit 1, and draw each steel structure manufacturing unit 1 production drawing;

[0024] 3) Draw the mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com