Automatic assembly line for flanging, loading and bottoming paper cans

An assembly line and paper can technology, applied in the field of automated assembly lines, can solve the problems of increased labor and time costs, low production efficiency, and high labor costs, and achieve the effects of saving manpower, convenient operation, and optimized glue application accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

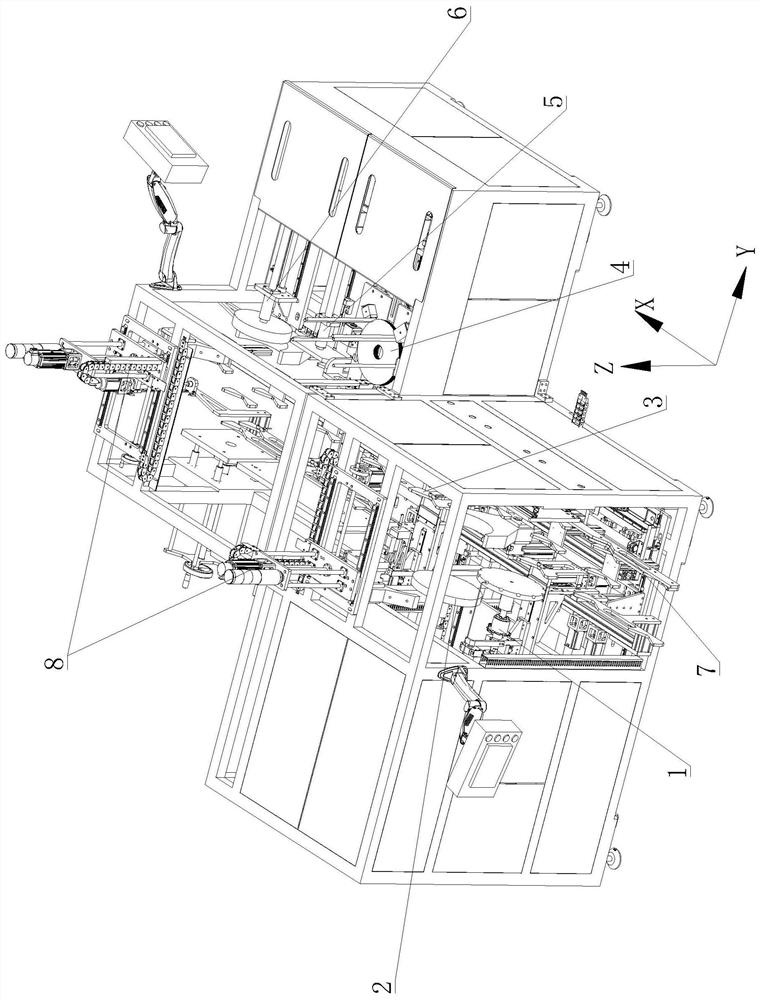

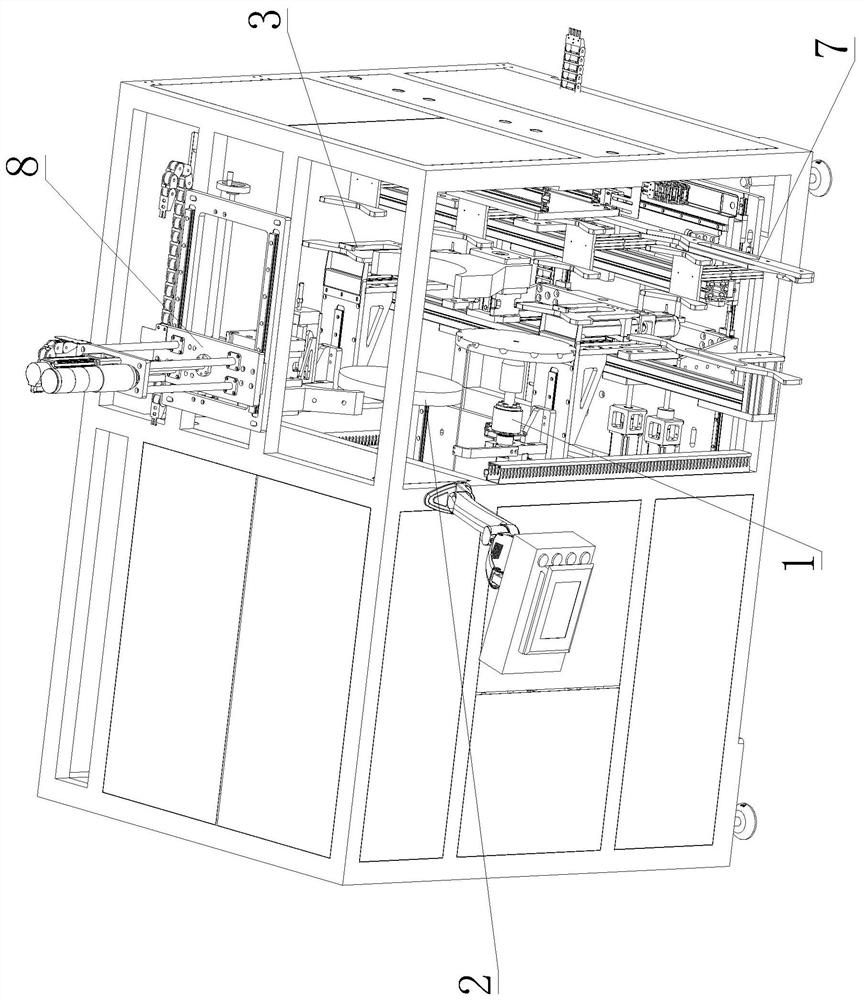

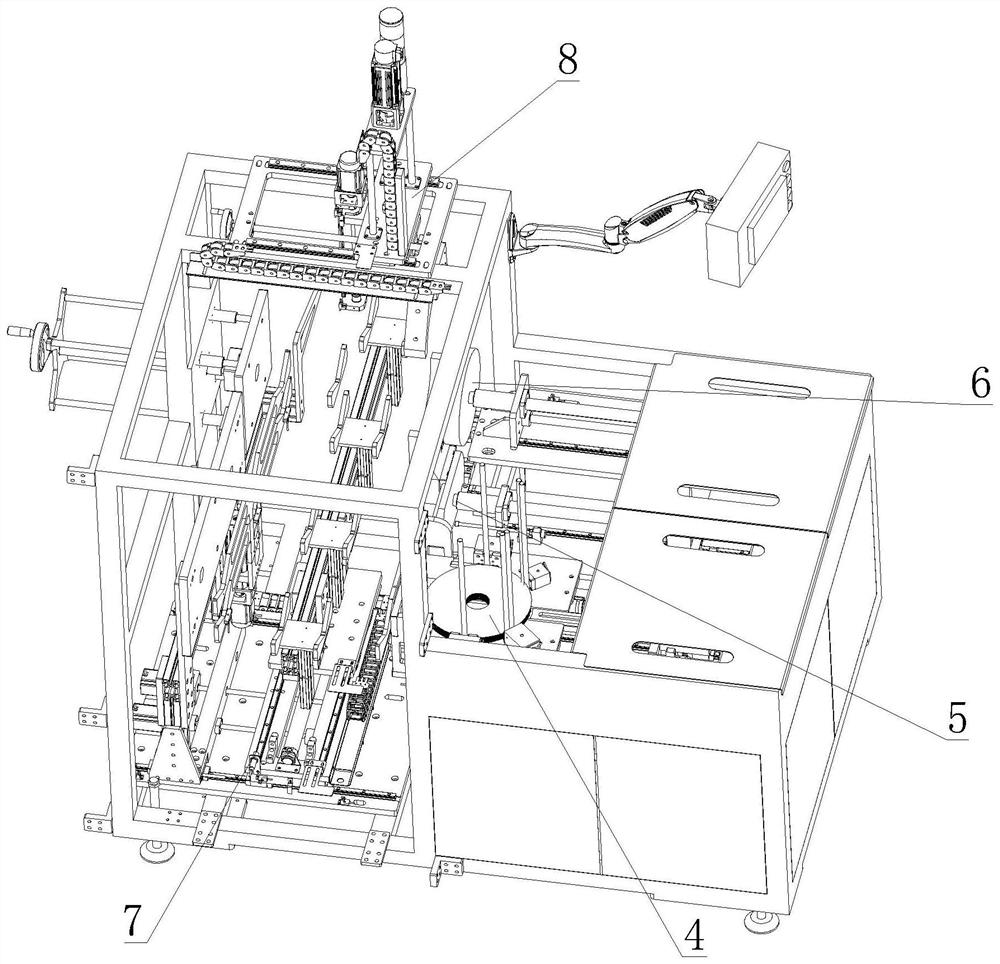

[0029] An automatic assembly line for flanging, topping and bottoming paper cans proposed by the present invention, including a front end, a rear end and a transport positioning mechanism 7 that runs through the front end and the rear end;

[0030] Such as Figure 1-3 As shown, the front end and the rear end are all provided with a clamping mechanism 8 for clamping the paper can; in the transport direction of the transport positioning mechanism 7, the front end is sequentially provided with an oiling mechanism 1 for oiling the end face of the paper can. The flanging mechanism 2 for bending the end face of the paper can and the glue spraying mechanism 3 for spraying glue on the inner wall of the paper can; in the transportation direction of the transportation positioning mechanism 7, the rear end is sequentially provided with a feeder for pushing the paper into the inside of the paper can. sheet mechanism 4, a slant sheet mechanism 5 for feeding paper sheets into the paper can ...

Embodiment 2

[0033] Such as Figure 4 As shown, the present invention proposes an automatic assembly line for flanging, topping and bottoming paper cans. Compared with Embodiment 1, the oiling mechanism 1 includes an oiled stepping motor 1-1, an oiled mini cylinder 1-3, oiled slide rail 1-4, thin oil inlet pipe 1-6, oiled expansion sleeve 1-7, oiled drill chuck 1-8, oiled coupling 1-10, thin oil inlet pipe Clip 1-11, oiled stepper motor frame 1-12, oiled upper frame 1-13, oiled cylinder frame 1-14, oiled cylinder frame support plate 1-15, oiled horizontal frame 1-16, oiled slide rail upper connector 1-17, oiled large triangular support plate 1-18, oiled lower frame 1-19, oiled motor frame with brake 1-20, righting fixture 1-21, Grease the upper frame support plate 1-22 and the oil pan 1-23;

[0034] The oil-coated stepper motor 1-1 is installed on the oil-coated stepper motor frame 1-12; the oil-coated stepper motor frame 1-12 is connected with the oil-coated upper frame 1-13; the oil-co...

Embodiment 3

[0037] Such as Figure 5-6 As shown, the present invention proposes an automatic assembly line for flanging, topping and bottoming paper cans. Compared with Embodiment 1, the flanging mechanism 2 includes a flanging three-phase asynchronous motor 2-1, a large flanging Servo motor 2-2, synchronous belt module 2-3, ball screw module 2-4, flange slide rail 2-5, expansion sleeve shaft 2-6, flange drill chuck 2-7, three-phase Asynchronous motor pad 2-9, three-phase asynchronous motor horizontal frame 2-10, flanged frame 2-12, large servo motor frame 2-13, induction sheet metal parts 2-14, double bearing housing 2- 15. Double bearing seat fixed frame 2-16, flanging triangular support plate 2-17 and flanging mold 2-18;

[0038] The flanging three-phase asynchronous motor 2-1 is installed on the three-phase asynchronous motor horizontal frame 2-10 through the three-phase asynchronous motor pad 2-9, and the flanging three-phase asynchronous motor 2-1 passes through the expansion sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com