One-time leveling method for installation of large bridge support

A bridge bearing, a one-time technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of bridge safety hazards, limited operating space on the top of pier columns, difficult to meet the requirements of bearing leveling, etc., to achieve cost saving, The effect of improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

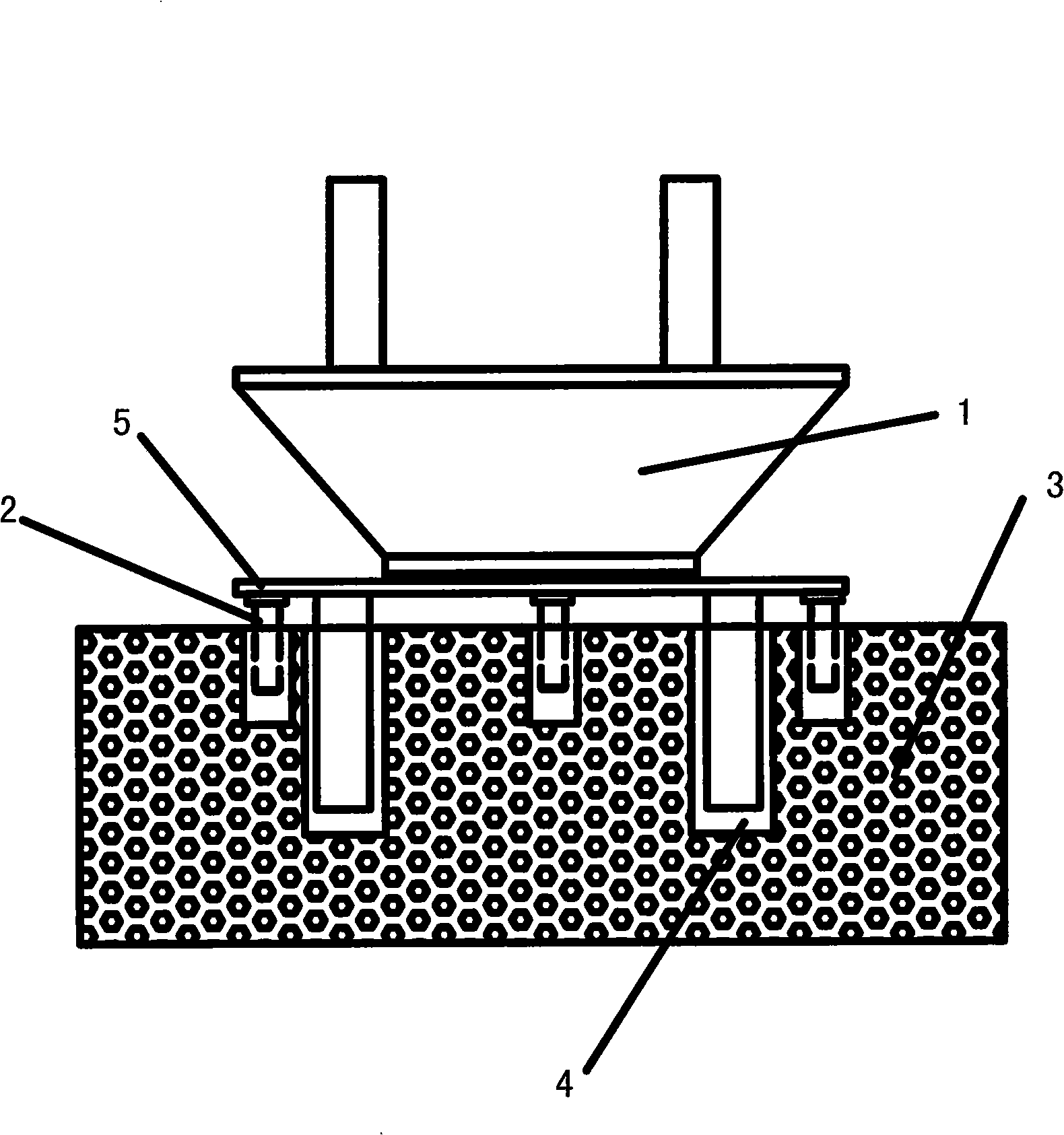

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0013] a. Select four leveling bolts (2) according to the size of the support (1), screw all the screw rods of the leveling bolts (2) with nuts, determine the geometric dimensions of the backing plate (5) under the support, and pour Leave a reserved hole (4) for the support anchor bolt in front of the pad stone (3), and pre-embed four leveling bolts (2) with nuts in the pad stone (3), so that the leveling bolts (2) The nut is higher than the top surface of the backing stone (3), and the pre-embedded position of the leveling bolt (2) is guaranteed to be within the vertical and horizontal range of the backing plate (5) under the support;

[0014] b. When the concrete strength of the backing stone (3) reaches more than 20Mpa, firstly rotate the four pre-embedded leveling bolts (2) to make the top elevation consistent with the bottom surface elevation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com