Gas sensor and manufacturing technique thereof

A technology of gas sensor and manufacturing process, which is applied in the direction of manufacturing microstructure devices, metal material coating technology, and technology for producing decorative surface effects, etc. It can solve problems such as power loss and reduce power consumption and use power consumption , The effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

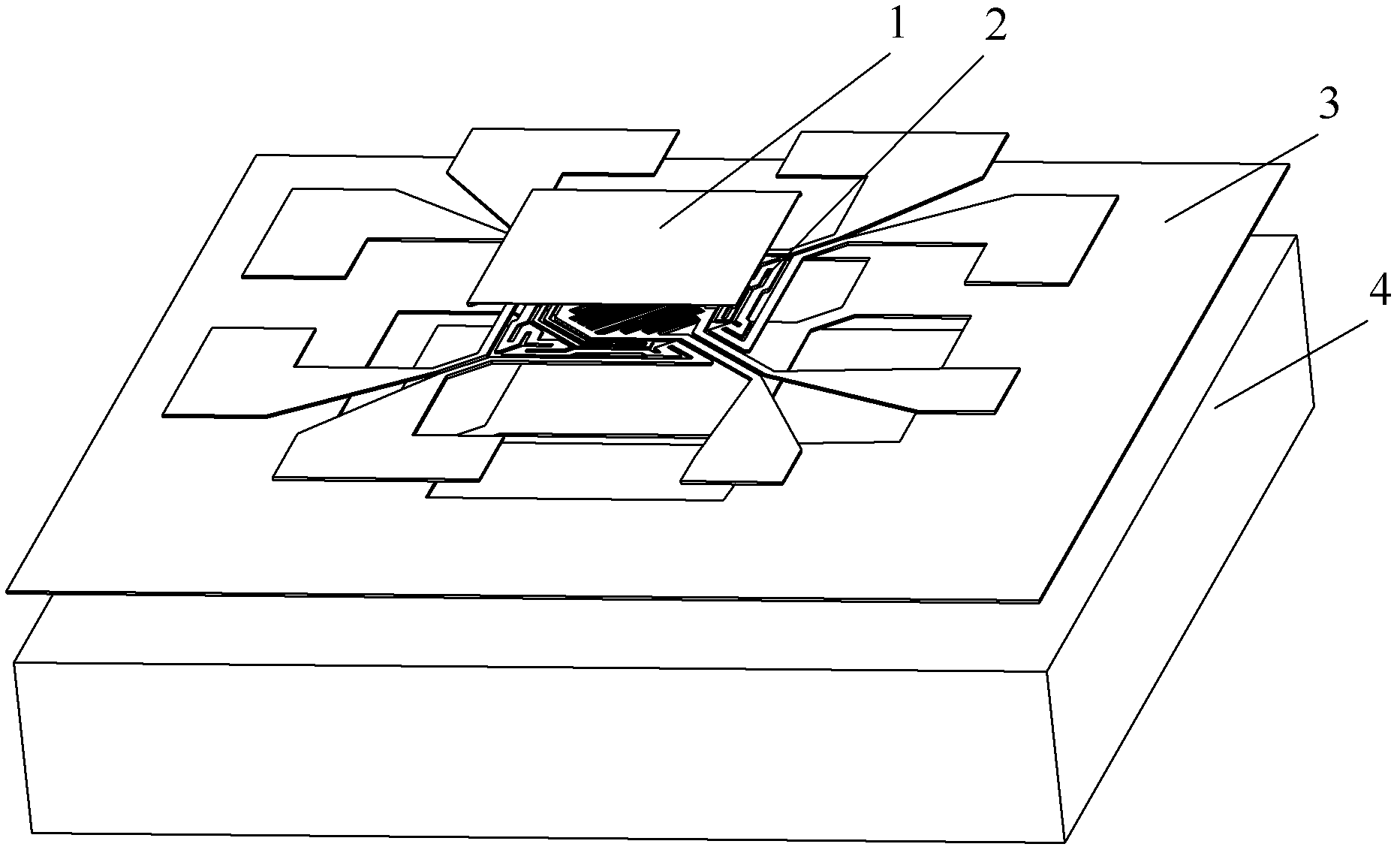

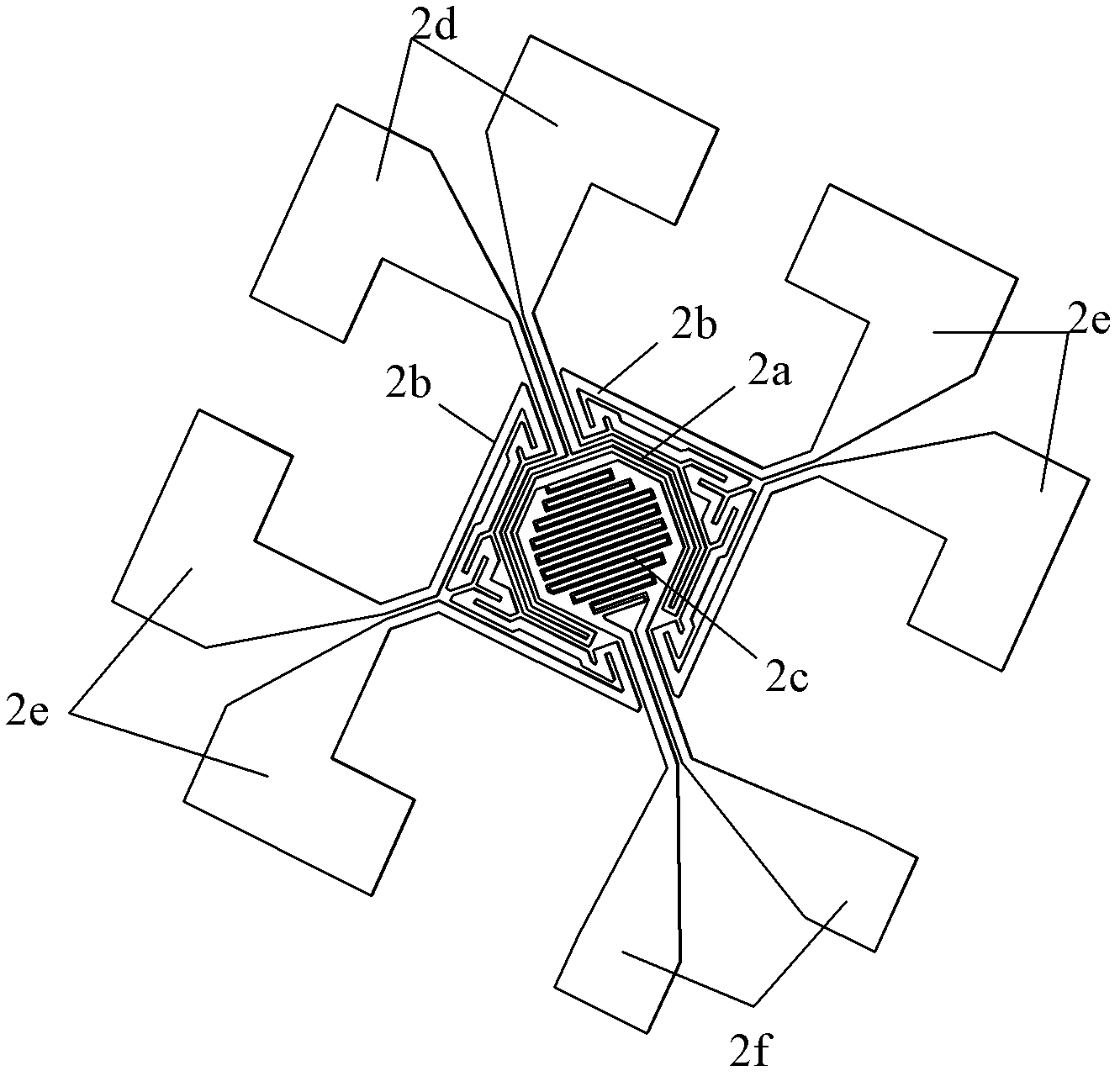

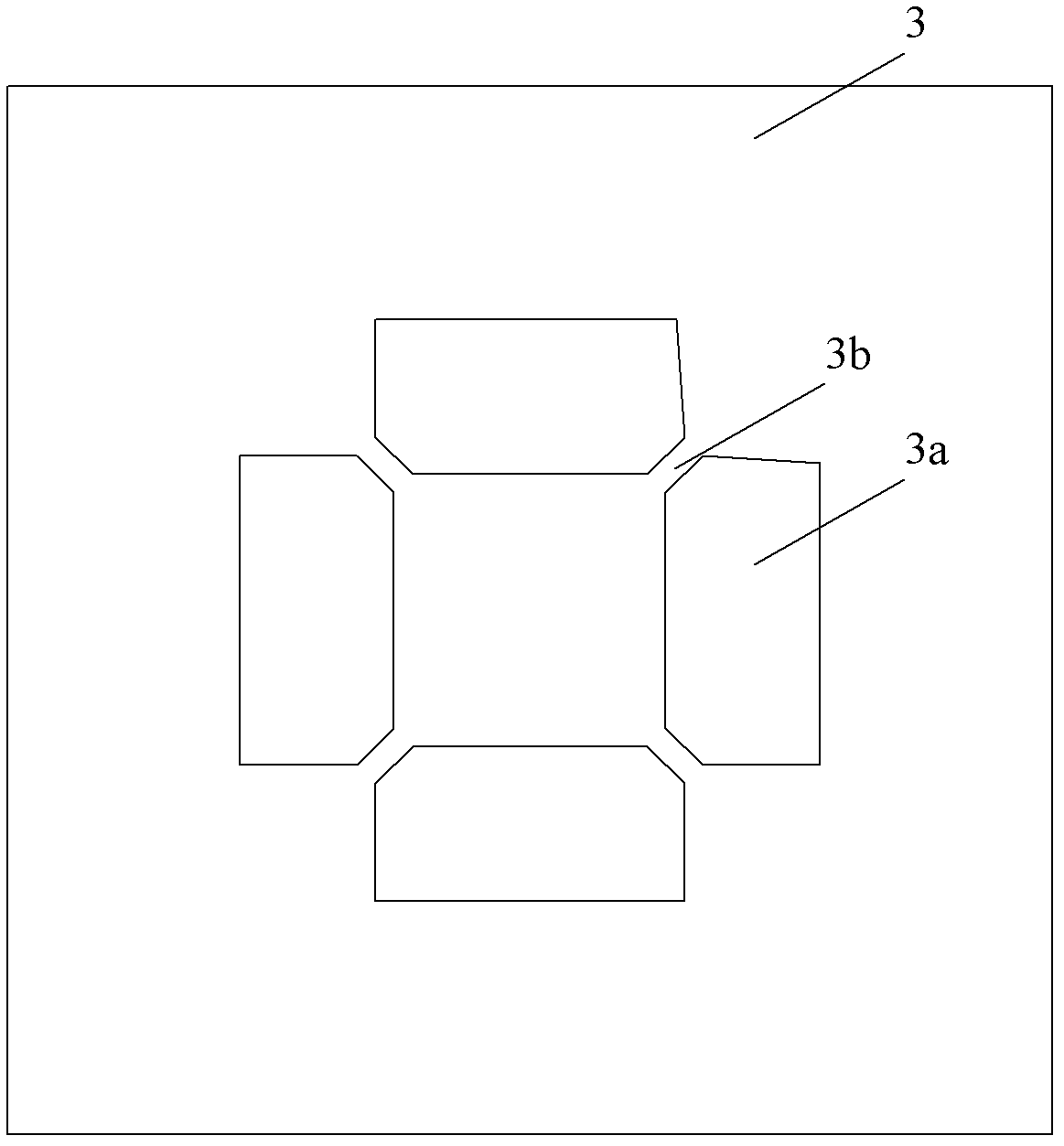

[0043] Such as figure 1 , figure 2 as well as image 3 As shown, the metal oxide semiconductor nanometer film gas sensor of the present invention includes a single crystal silicon substrate 4, a silicon dioxide layer 3 on the upper surface of the silicon substrate, an interdigital signal electrode 2c, a temperature measuring electrode 2a, and a heating electrode 2b; The silicon substrate 4 has a through-hole structure, which is a square through-hole whose wall is perpendicular to the upper and lower surfaces of the substrate. The silicon dioxide layer 3 is provided with windows 3a, and the part between adjacent windows constitutes a cantilever structure 3b. The upper surface of the silicon dioxide layer 3 is provided with an electrode group 2 composed of an interdigital signal electrode 2c, a temperature measuring electrode 2a and a heating electrode 2b, and the upper surface of the electrode group 2 is provided with a tin dioxide gas-sensitive thin film layer 1 . The temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com